6. Fuel injection equipment

140

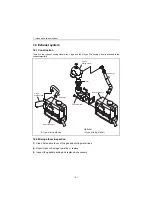

6.1.4 Removing a fuel injection pump

The procedure to remove a fuel injection pump from the gear case is shown.

[NOTICE]

Be sure to remove a flange and a fuel injection pump

drive gear with a pair without loosening the flange

bolts.

1) Remove fuel injection pipes, fuel pipes and a

remote control wire. Block the entrance with tape

so that trash may not enter the fuel injection pipes

and the fuel injection pump.

2) Mark the position of the timing marks of a fuel

pump and a gear case. Or, put a mark on the

gear case at the position to agree the timing mark

of a fuel pump.

3) Remove a pump cover from the gear case.

4) Give the marks on a fuel injection pump drive gear

and a idle gear with paint or the like.

5) Loosen fuel injection pump installation nuts (three nuts).

6) Loosen a installation nut of a fuel injection pump drive gear.

7) Pull a fuel injection pump drive gear and a flange with a pair to your side by gear puller.

8) Remove a pump drive gear nut and a washer.

9) Remove a fuel injection pump. Leave the pump drive gear in the gear case.

6.1.5 Installing a fuel injection pump

[NOTICE]

• Use a new O-ring on the fuel pump flange and apply grease.

• Confirm whether the marks of the pump drive gear and the idle gear is correct.

1) Turn a camshaft so that the key of the pump camshaft may almost agree in a position of the key

groove of a pump drive gear.

2) Insert a fuel injection pump into the installation hole of the gear case straight to prevent the

damage of the O-ring. Insert a fuel pump while confirming whether the key of a camshaft and the

key groove of a drive gear agree.

3) Assemble a pump drive gear nut and a washer together temporarily.

4) Turn a fuel injection pump to the position where the marks of the fuel injection pump and the gear

case agrees.

5) Fasten pump installation nuts (three nuts) on the fuel injection pump.

6) Tighten the pump installation nut by the specified standard torque.

Tightening torque of the pump drive gear nut (without lube oil)

6.1.6 Adjusting fuel injection timing

Refer to 2.2.6(1) in chapter 2.

Tightening torque

N•m(kgf•m)

58.8-68.8 (6.0-7.0)

Fuel injection pump

Flange

Flange bolt

Spring

washer

Pump drive gear nut

Fuel injection pump

drive gear

Don't disassemble

Содержание 3YM20

Страница 1: ...M9961 03E100 ...

Страница 41: ...2 Inspection and adjustment 26 Cylinder head Bracket Fuel filter Fuel pipe Fuel injection pump Clamp Fuel pipe ...

Страница 154: ...6 Fuel injection equipment 139 6 1 3 Fuel injection pump structure Section of a fuel injection pump governor for 3YM30 ...