2. Inspection and Adjustment

(4) Intake/exhaust valve clearance adjustment

Make measurement and adjustment while the engine

is cold.

(a) Valve clearance measurement

1) Remove the rocker arm cover above cylinder

head.

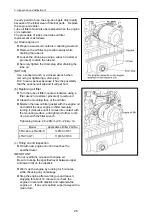

2) Set the No.1 cylinder in the compression TDC

Turn the crankshaft to bring the piston of the

No.1 cylinder to its compression top dead center

while watching the rocker arm motion, timing

scale and the top mark position of the crankshaft

pulley.

(Position where both the intake and exhaust

valves are closed.)

Notes:

The crankshaft shall be turned clockwise as seen

from the radiator side.

The No.1 cylinder position is on the opposite side

of the radiator and the ignition order shall be

1-3-4-2-1 at 180

°

intervals.

Since the intake and exhaust valve rocker arms

are operated the same and there is a clearance

between the arm and valve generally at the top

dead center, the position can be checked by

means of the play when the arm head is held with

a hand. Also see that the crankshaft pulley top

mark is positioned at zero on the timing scale. If

there is no valve clearance, inspection in the

disassembled state is necessary since the valve

seat may be worn abnormally.

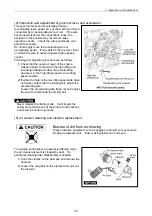

3) Valve clearance measurement

In case of 2-valve cylinder head insert a

thickness gage between the rocker arm and

valve cap, and record the measured valve

clearance.

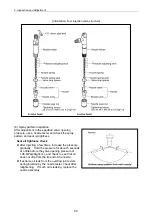

In case of 4-valve head insert a thickness gage

between the rocker arm and the valve bridge,

and record the measured valve clearance.

(Use it as the data for estimating the wear state.)

4) Adjusting other cylinders

In case of 4-cylinder engines, turn the crankshaft

180 and make adjustment for the No.3 cylinder.

Then adjust the No.4 and No.2 cylinders in this

order.

The cylinder to be adjusted first does not have to

be the No.1 cylinder. Select and adjust the

cylinder where the piston is the nearest to the top

dead center after turning, and make adjustment

for other cylinders in the order of ignition by

turning the crankshaft 180 each time.

In case of 3-cylinder engines, turn the crankshaft

240 and make adjustment for the No.3 cylinder.

Then adjust the No.2 cylinder in this order.

40

Содержание 3TNV Series

Страница 1: ...4TNV106 4TNV106T 4TNV94L 4TNV98 4TNV98T 3TNV82A 3TNV84 T 4TNV84 T 3TNV88 4TNV88 ...

Страница 31: ...1 General 1 4 Engine External Views 16 ...

Страница 32: ...1 General 1 5 Structural Description 17 ...

Страница 127: ...6 Cooling System 6 COOLING SYSTEM 6 1 Cooling Water System 6 2 Cooling Water Pump Components 112 ...

Страница 156: ...9 Starting Motor 9 1 2 Components 141 ...

Страница 157: ...9 Starting Motor 9 1 3 Troubleshooting 142 ...

Страница 172: ...9 Starting Motor 9 2 3 Troubleshooting 157 ...

Страница 175: ...9 Starting Motor 2 Removal of magnetic switch Remove the M6 bolts 10mm 2 160 ...

Страница 185: ...9 Starting Motor 3 Brush 1 Check wear of the brush and the brush spring force 170 ...

Страница 194: ...10 Alternator 179 10 1 6 Troubleshooting ...

Страница 195: ...11 Electric Wiring 180 11 ELECTRIC WIRING 11 1 Electric Wiring Diagram ...

Страница 213: ......