4. Disassembly, Inspection and Reassembly of Engines

107

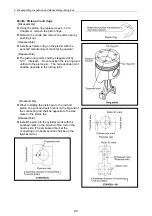

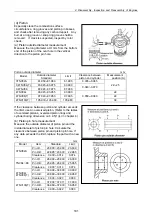

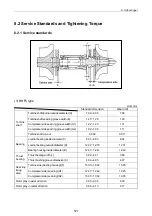

3) Apply the honing fluid to the Flex-Hone and turn

the electric drill at 300 to 1200 rpm. Then insert

the Flex-Hone into the cylinder bore while turning

it, and move it up and down for about 30 sec. to

obtain a honing mark with a cross hatch angle of

30 to 40 .

[NOTICE]

1) Avoid faster revolution than 1200 rpm since it

may cause breakdown.

2) Do not insert or extract the Flex-Hone in

stopped state because the cylinder will be

damaged.

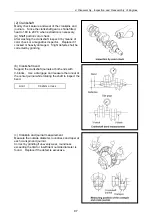

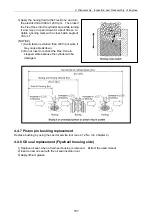

4.4.7 Piston pin bushing replacement

Replace bushing by using the special service tool (see 4.1.2 No.3 in Chapter 4).

4.4.8 Oil seal replacement (Flywheel housing side)

1) Replace oil seal, when a flywheel housing is removed. Extract the used oil seal.

2) Insert a new oil seal with the oil seal insertion tool.

3) Apply lithium grease.

Содержание 3TNV Series

Страница 1: ...4TNV106 4TNV106T 4TNV94L 4TNV98 4TNV98T 3TNV82A 3TNV84 T 4TNV84 T 3TNV88 4TNV88 ...

Страница 31: ...1 General 1 4 Engine External Views 16 ...

Страница 32: ...1 General 1 5 Structural Description 17 ...

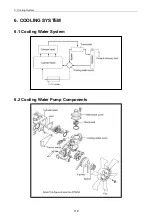

Страница 127: ...6 Cooling System 6 COOLING SYSTEM 6 1 Cooling Water System 6 2 Cooling Water Pump Components 112 ...

Страница 156: ...9 Starting Motor 9 1 2 Components 141 ...

Страница 157: ...9 Starting Motor 9 1 3 Troubleshooting 142 ...

Страница 172: ...9 Starting Motor 9 2 3 Troubleshooting 157 ...

Страница 175: ...9 Starting Motor 2 Removal of magnetic switch Remove the M6 bolts 10mm 2 160 ...

Страница 185: ...9 Starting Motor 3 Brush 1 Check wear of the brush and the brush spring force 170 ...

Страница 194: ...10 Alternator 179 10 1 6 Troubleshooting ...

Страница 195: ...11 Electric Wiring 180 11 ELECTRIC WIRING 11 1 Electric Wiring Diagram ...

Страница 213: ......