2. Inspection and Adjustment

IMPORTANT:

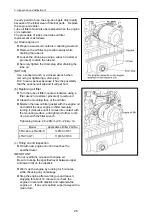

If the coolant water runs short quickly or when the radiator runs short of water with the Coolant

recovery tank level unchanged, water may be leaking or the air tightness may be lost. Increase in

the Coolant recovery tank water level during operation is not abnormal.

The increased water in the Coolant recovery tank returns to the radiator when the engine is cooled

down.

If the water level is normal in the Coolant recovery tank but low in the radiator, check loosened

clamping of the rubber hose between the radiator and Coolant recovery tank or tear in the hose.

Standard

Engine: The radiator shall be filled up.

(Unit: liter)

Model

Coolant water volume In an engine

3TNV82A 1.8

3TNV84(T)

3TNV88

2.0

4TNV84(T)

4TNV88

2.7

4TNV94L

4TNV98(T)

4.2

4TNV106(T) 6.0

Engine coolant water capacity may differ from the above

volume depending on an engine installed on a machine unit.

(5) Fuel pipe and coolant water pipe inspection and maintenance

Check the rubber hoses for fuel and coolant water pipes cracked. If the cracked hose is found,

replace it with new one. Check the loosened clamp. If found, tighten it.

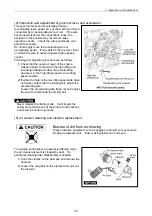

(6) Inspection and adjustment of governor lever and accelerator

Make sure the accelerator of the machine unit can be operated smoothly before starting the engine. If

it feels heavy to manipulate, lubricate the accelerator cable joints and pivots. Adjust the accelerator

cable if there is a dislocation or excessive play between the accelerator and the governor lever. Refer

to 3.2.3.

(7) Warning lamp & instruments function check

Before and after starting the engine, check to see that the alarm function normally. Failure of alarm

cannot warn the lack of the engine oil or the coolant water. Make it a rule to check the alarm operation

before and after starting engine every day. Refer to each manual for machine units in details.

2.2.2 inspection after initial 50 hours operation

Be sure to check the following points after initial 50 hours operation, thereafter every 250 hours or 3

months operation.

No. Inspection

Item

(1)

Lube oil and filter replacement

(2)

V-belt tension check

(1) Lube oil and filter replacement (1st time)

When an engine is still hot, be careful with a splash of engine oil which

may cause burns. Replace engine oil after the engine oil becomes warm.

It is most effective to drain the engine oil while the engine is still warm.

25

Содержание 3TNV Series

Страница 1: ...4TNV106 4TNV106T 4TNV94L 4TNV98 4TNV98T 3TNV82A 3TNV84 T 4TNV84 T 3TNV88 4TNV88 ...

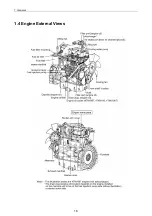

Страница 31: ...1 General 1 4 Engine External Views 16 ...

Страница 32: ...1 General 1 5 Structural Description 17 ...

Страница 127: ...6 Cooling System 6 COOLING SYSTEM 6 1 Cooling Water System 6 2 Cooling Water Pump Components 112 ...

Страница 156: ...9 Starting Motor 9 1 2 Components 141 ...

Страница 157: ...9 Starting Motor 9 1 3 Troubleshooting 142 ...

Страница 172: ...9 Starting Motor 9 2 3 Troubleshooting 157 ...

Страница 175: ...9 Starting Motor 2 Removal of magnetic switch Remove the M6 bolts 10mm 2 160 ...

Страница 185: ...9 Starting Motor 3 Brush 1 Check wear of the brush and the brush spring force 170 ...

Страница 194: ...10 Alternator 179 10 1 6 Troubleshooting ...

Страница 195: ...11 Electric Wiring 180 11 ELECTRIC WIRING 11 1 Electric Wiring Diagram ...

Страница 213: ......