11

P/N 10001646 Rev. AA

June 2015

MAINTENANCE

INSPECTION

To maintain continuous and satisfactory operation, a regular

inspection procedure must be initiated so that worn or damaged

parts can be replaced before they become unsafe. The intervals of

inspection must be determined by the individual application and are

based upon the type of service to which the hoist will be subjected.

The inspection of hoists is divided into two general classifications

designated as “frequent” and “periodic.”

Frequent Inspections:

These inspections are visual examinations by the operator or other

designated personnel. The frequent inspections are to be performed

daily and shall include the following items (no records required):

a. Braking mechanisms for evidence of slippage daily.

b. Load Chain for lubricant, wear, damaged links or foreign

material-daily (See pages 11, 12 & to 15).

c. Cracks or damage to housing, abnormal noises or operation,

damaged hooks (see Hook Inspection below).

d. All capacity and warning labels legible and present.

Any deficiencies noted are to be corrected before the hoist

is returned to service.

Periodic Inspections:

These are inspections by an appointed person who makes records

of apparent external conditions to provide the basis for a continuing

evaluation. For normal service, the periodic inspections are to be

performed yearly and for heavy service, the periodic inspections

are to be performed semi-annually.

Due to the construction of the hoist, it will be necessary to partially

disassemble the unit to perform the periodic inspections. The

periodic inspections are to include those items listed under frequent

inspections as well as the following:

a. Chain for excessive wear or stretch (See pages 11 to 12).

b. Worn, cracked or distorted parts such as hook blocks, hand

chain guides, chain guide, stripper, loose end connector, shafts,

gears, bushings and bearings.

c. Inspect for wear on the tip of the driver, stops on handwheel

and pockets of the liftwheel and handwheel.

d. Loose or missing screws, nuts, pins or cotter pins.

e. Inspect brake components for worn, glazed or contaminated

brake disc and scoring of the brake hub and brake plate. If the

thickness of the friction washer is less than 1/32 inch, it should

be replaced.

f. Replace missing or damaged warning labels.

g. Corroded, stretched or broken brake spring.

h. Hooks-dye penetrant, magnetic particle or other suitable crack-

detecting inspections should be performed at least once a year,

if external conditions indicate there has been unusual usage.

Any deficiencies noted are to be corrected before the hoist is

returned to service. Also, the external conditions may show the need

for more detailed inspection which, in turn, may require the use of

nondestructive-type testing.

Any parts that are deemed unserviceable are to be replaced with new

Columbus McKinnon parts before the unit is returned to service. It is

very important that the unserviceable parts be destroyed to prevent

possible future use as a repair item and properly disposed of.

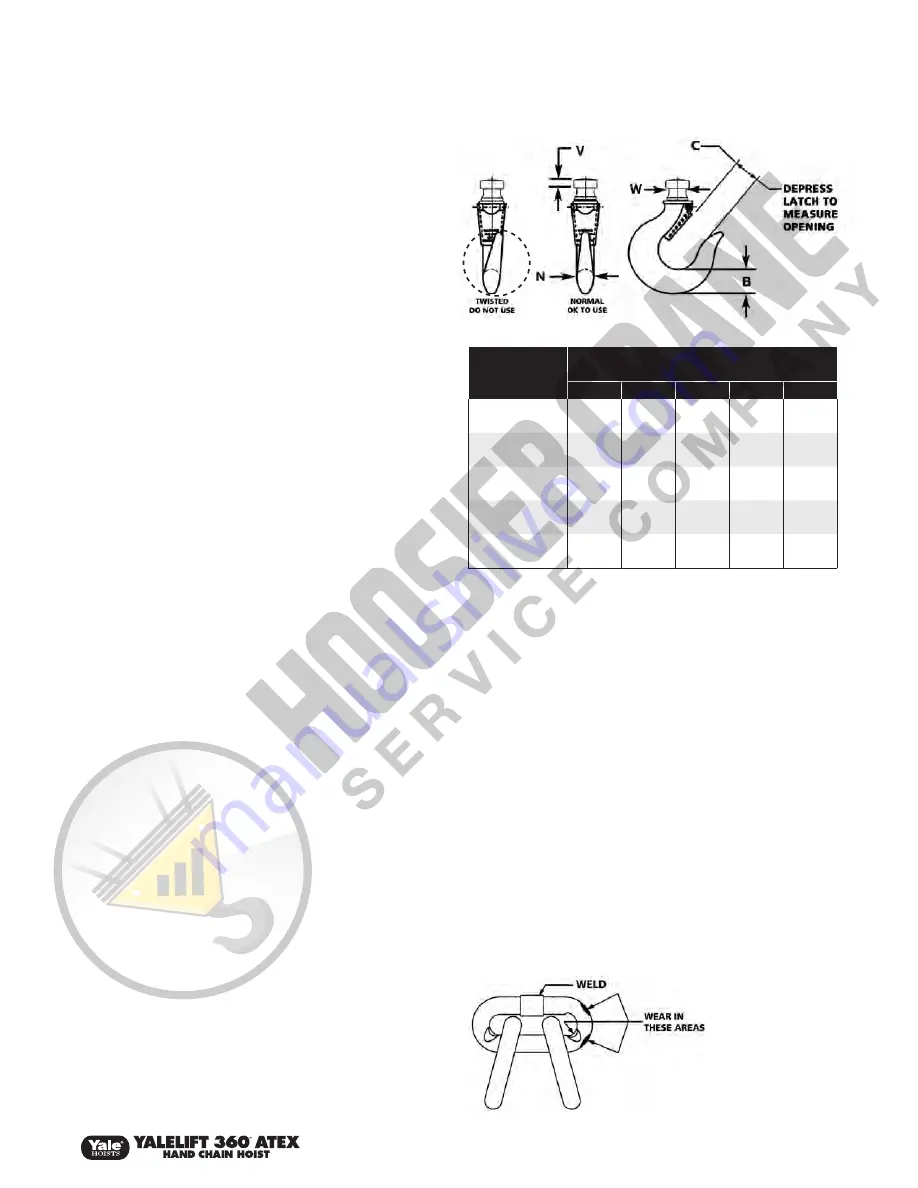

Hook Inspection

Hooks damaged from chemicals, deformation or cracks, or that have

a twist, excessive opening or seat wear, must be replaced. Also,

hooks that are opened to the extent that the latch does not engage

the tip must be replaced. Any hook that is twisted or has excessive

throat opening indicated abuse or overloading of the hoist. Other

load sustaining parts should be inspected for damage.

Check to assure the latch is not damaged or bent and that it operates

properly. It should have sufficient spring pressure to keep it tightly

against the tip of the hook and allow it to spring back to the tip when

released. If the latch does not operate properly, replace the latch.

LOAD CHAIN

Chain should feed smoothly into and away from the hoist. If chain

binds, jumps or is noisy, first clean and lubricate it (See next page). If

trouble persists, inspect chain and mating parts for wear, distortion

or other damage.

Chain Inspection

First clean chain with a non-caustic/non-acid type solvent and make

a link by link inspection for nicks, gouges, twisted links, weld spatter,

corrosion pits, striations (minute parallel lines), cracks in weld areas,

wear and stretching. Chain with any one of these defects must be

replaced.

Slack the portion of the chain that normally passes over the

liftwheel. Examine the interlink area for the point of maximum wear

(polishing). Measure and record the stock diameter at this point of

the link. Then measure stock diameter in the same area on the link

that does not pass over the liftwheel (use the link adjacent to the

loose end connector

for this purpose).

Compare these two

measurements. If the

stock diameter of the

worn link is 0.010 inch,

or more, less than the

stock diameter of the

unworn link, the chain

must be replaced.

TROLLEY

(YLITP/YLITG MODELS)

Check to make sure the side plates are parallel to each other.

Also, all wheels must be in contact with the beam flange.

ATTENTION: The trolley must never be used on beams with flange

widths that exceed the maximum adjustable width of the trolley.

Check the travel path before starting work to allow for unit to run

faultless on the beam. Any existing obstacles must be removed.

In addition, check the correct fastening and position of the end stops.

Figure 3 – Hook Inspection

Figure 4 - Chain Inspection

Capacity

(ton)

Critical Hook Dimensions

in.

(mm)

B

C

N

V

W

¼, ½ & 1

0.87

1.14

0.75

0.24

0.59

(22)

(29)

(19)

(6)

(15)

1½ & 2

1.50

1.58

1.18

0.43

0.87

(38)

(40)

(30)

(11)

(22)

3 & 4

1.77

1.85

1.46

0.47

1.10

(45)

(47)

(37)

(12)

(28)

5 & 6

2.68

2.68

1.97

0.67

1.38

(68)

(68)

(50)

(17)

(35)

8, 10 & 12

3.35

2.52

2.21

0.51

1.77

(85)

(64)

(56)

(13)

(45)

Hooks shall swivel freely under no load conditions. If there is any

binding, the hooks must be replaced. Also, replace hook if opening

is greater than “C” or if the thickness at “B”, “N”, “W”, or “V” is less

than the dimensions listed in the chart (see Figure 3).