12

P/N 10001646 Rev. AA

June 2015

Using other than Columbus McKinnon supplied load chain may

cause the chain to jam in the hoist and/or allow the chain to break

and the load to drop.

TO AVOID INJURY:

Due to size requirements and physical properties, use only

Columbus McKinnon supplied load chain in the Yale Yalelift 360™

ATEX hand chain hoist.

Used motor oils contain known carcinogenic materials.

TO AVOID INJURY:

Never use used motor oils as a chain lubricant. Only use Lubriplate

®

Bar and Chain Oil 10-R as a lubricant for the load chain.

Worn chain can be an indication of worn hoist components. For

this reason, the hoist’s chain guide, stripper and liftwheel should be

examined for wear and replaced as necessary when replacing worn

chain (See “DISASSEMBLY AND ASSEMBLY”).

Also, the load chain is specially heat treated and hardened and

should never be repaired.

IMPORTANT: Do not use replaced chain for other purposes such

as lifting or pulling. Load chain may break suddenly without visual

deformation. For this reason, cut replaced chain into short lengths to

prevent use and then dispose of it.

NOTE: The above method of inspecting load chain can also be used

to inspect the hand chain for stretch and wear.

Chain Lubrication

A small amount of lubricant will greatly increase the life of load chain.

Do not allow the chain to run dry. Keep it clean and lubricate at

regular intervals with Lubriplate

®

Bar and Chain Oil 10-R (Fiske Bros.

Refining Co.) or equal lubricant. Normally, weekly lubrication and

cleaning is satisfactory, but under hot and dirty conditions, it may

be necessary to clean the chain at least once a day and lubricate it

several times between cleanings.

When lubricating the chain, apply sufficient lubricant to obtain

natural run-off and full coverage, especially in the interlink area.

Also check chain for stretch and wear using a vernier caliper as

shown in Figure 5. Select an unused, unstretched section of chain

(usually at the loose end) and measure and record the length over 11

chain links (pitches). Measure and record the same length on a worn

section of chain. If the result (amount of stretch and wear) is greater

than 0.145 inch, the chain must be replaced.

Figure 5 - Chain Inspection

Use only a “Knife-Edge” caliper to eliminate the possibility of a false

reading by not measuring full pitch length.

LUBRICATION

Hoist normally requires no additional lubrication except when it had

been disassembled for cleaning or repairs.

IMPORTANT: Brake is designed to operate dry. Do not use any

grease or lubricant on the braking surfaces. When lubricating parts

adjacent to the brake, do not use an excessive amount of lubricant

which could seep onto the brake surfaces.

MAINTENANCE (CONTINUED)

If hoist is disassembled for service, repair or inspection, remove and

clean existing grease from unit and replace with approximately 1

oz. of Poliplex 2 (Century Lubricants Co.) grease or equal lubricant

to the exterior surface of the drive shaft, gears, internal thread of

brake hub, surface of liftwheel bushings (1/2 ton unit), bushings in

the gear side plate and gear cover, internal and external surfaces of

handwheel bushings and rim of handwheel cover.

IMPORTANT: To assure long life and top performance, be sure to

lubricate the various parts of the hoist using the lubricants specified

above. If desired, these lubricants can be purchased from Columbus

McKinnon (See Figure 7, page 15).

REPLACING LOAD CHAIN

To replace the load chain, remove the lower hook block from the

chain. Disconnect the chain from the loose end connector and

operate the hoist in the lowering direction to run the chain out of the

hoist. Feed a length of soft wire up and over the liftwheel. Attach

the wire to the new load chain so that the chain will be entering the

center of the hoist frame. Position the chain so that the first link

to engage the liftwheel is an upstanding link and the weld on all

upstanding links will be away from the liftwheel. Pull on the wire until

the chain engages the liftwheel. Rotate the handwheel until the chain

comes out on the loose side of the hoist. Attach the chain to the

loose end connector and attach the lower hook block assembly to

the chain so that the lower hook is directly below the upper hook.

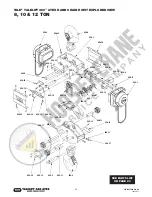

DISASSEMBLY AND ASSEMBLY

The parts list and exploded view on pages 15 to 27 show the general

arrangement and name of the parts of the Yale Yalelift 360™ ATEX

hand chain hoist. These should be used when disassembling and

reassembling the hoists so that all parts are properly installed.

1. To inspect or replace parts of the load brake system, it is

necessary to partially disassemble the hoist. Remove the hand

chain wheel cover and slide it down the hand chain . Lift the hand

chain out of the hand chain wheel pockets. Remove the cotter

pin, castle nut and washer from the drive shaft. Remove hand

chain wheel by turning hand chain wheel counter clockwise.

Inspect the friction surface of the brake hub and replace it if

the surface excessively scored. (see page 13, “HANDWHEEL

OVERLOAD CLUTCH ASSEMBLY”). Slide front brake disc, ratchet

disc assembly and rear brake disc from pressure disk. Remove

retaining ring and remove pressure disc by turning counter

clockwise. Inspect both brake discs and replace if excessive wear,

scoring, glazing or contamination is found. If brake discs are worn

down to the following thickness, replacement is required:

Capacity

Thickness Min.

in. (mm)

¼, ½, 1, 1½ & 2

.043

(1.09)

3, 4, 5, 6, 8, 10 & 12

.063

(1.60)

Inspect ratchet disc assembly and pressure disc

friction surfaces, replace if excessively scored.

After the brake discs are inspected or replaced, reassemble

the hoist in reverse to the order given above.

Using any grease or lubricant on the braking surfaces will cause

brake slippage and loss of load control which may result in injury

and/or property damage.

TO AVOID INJURY:

Do not use any grease or lubricant on braking surfaces. The brake is

designed to operate dry.