11

12

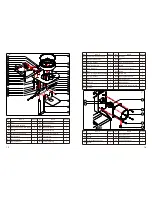

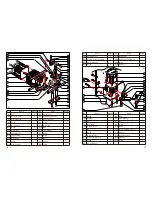

VIII. Explosive View for Dismounting

A

Fault

Code

Fault Status

Fault Cause

Solutions

E06

1. Appear during start up

1. Lower sensor fails or poor

contact of lower sensor plug.

2. Upper mold motor fails

1. Open the rear cover, then, pull

out and insert

DOWN

at the

adapter plate, and restart the

machine after confirmation.

2. Please contact the company.

2. While using, the upper

mold fails to drop to the

designated position.

3. The lower mold touches

the lower limit column.

E07

The warning indicator

lamp goes on, and the

lower mold extends out

along with continuous tick

sound

The safety door cannot be set at

the located position due to the

touch on safety door switch, the

safety door micro-switch fails or

there is a foreign matter

blockage.

1. Remove the foreign matter

which touches the safety door,

or move the safety door back

and forth to make it naturally

swing to the located position.

2. Please contact the company.

E19

All keys have no

response.

1.Main board fails.

2.The temperature of the heater

is above 250

℃

.

Please contact the company.

None

The film-sealing pattern

is uneven on left and right

sides.

Incorrect film photo sensor

position

Adjust the film photo sensor

position, for pattern deviation to

the left, please adjust the film

photo sensor upwards. For

pattern deviation to the right,

please adjust the film photo

sensor downwards.

None

After film-sealing

operation, the film is

melted to the cup mouth.

The temperature is too high.

It is suggested to adjust the

operating temperature

according to the film or properly

reduce the set temperature.

None

The sealing film is not

tight, water or air

leakage.

1. The film is incompatible with

the cup material.

Adopt the film applicable to the

cup material.

2. The heater is adhered with

syrup or foreign matter.

Cut off the main power, and

scrub the heater with slightly wet

cloth after it is completely

cooled.

3. The cup-sealing time is too

short.

Increase P-3 film-sealing time.

4. The set temperature for cup-

sealing is too low.

Increase P-1 film-sealing

temperature.

5.The cup may be deformed due

to improper storage

Replace the normal cup

6.The paper cups film is too

thin to sealing

Replace the normal cup

None

Draggy film cutting

The film cutter is not sharp

enough, or the film cutter is

adhered with foreign matter.

Continuously execute the cutter

soaking program, and then

remove the foreign matter.

None

The film cannot be

completely cut off.

Film chip or foreign matter exists

between the film cutter and the

heater.

Cut off the main power, and

remove the foreign matter after

it is completely cooled.

No.

Name

Quantity

No.

Name

Quantity

A1

Nut

2

A2

spring-washer

2

A3

Film support rod

2

A4

Screw

2

A5

Spring-washer

2

A6

Film support rod bracket

1

A7

Screw

4

A8

Film cutter

1

A9

Screw

4

A10

Flat-washer

4

A11

Spring

4

A12

Film-pressing cup

1

A13

Screw

4

A14

Film-sealing spring

4

A15

Heater

1

A16

Screw

1

A17

Temperature sensor

1

A18

Screw

3

A19

Support plate

1

A20

Film cutter holder

1

A21

Sealing cap

1