a “x1k” ohm range. Inspect the CDI & ignition coil unit

for continuity between plug cap and ground. If the tester

reading shows 4-10k

Ω

, secondary winding are in proper

condition.

Ignition coil secondary resistance

4-10k

Ω

Caution :

As the diode, condenser and SCR are provided in the

primary circuit, the primary circuit cannot be checked

by using an ohmmeter.

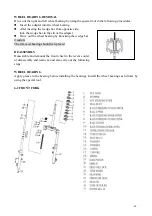

STATOR OIL

Using the pocket test, measure the resistance between

the B/R lead wire and stator base. If the resistance checked

is incorrect, replace the coil.

Standard resistance B/R –stator base (ground).

155

±

20%

Ω

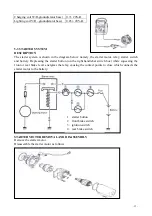

5-2 CHARGING AND LIGHTING SYSTEM

The charging system uses the flywheel magneto as shown in the figure. The charging and lighting

coils are mounted on the magneto stator and generate AC as the flywheel rotor turns. The charging

and lighting system incorporates two circuits, for charging and lighting. These circuits are engaged

by setting the ignition key to ON position. AC generated in the charging coil flows to the

regulator/rectifier where it is charged to DC and charging voltage is regulated. This DC then

charges the battery. On the other hand, lighting coil supplies AC current to the head light, meter

light and high beam indicator light under the regular condition.

CHARGING PERFORMANCE CHECK

Open the seat and disconnect the battery

○

-

lead. Set the pocket tester knob to DC ampere range

20A.

- 31 -