12

C

L

E

A

N

I

N

G

A

N

D

S

A

N

I

T

I

Z

I

N

G

I

N

S

T

R

U

C

T

I

O

N

S

EQUIPMENT AND SUPPLIES NECESSARY

•

Clean 5 gallon bucket (1)

•

Clean cloth towel (1)

•

Safety goggles and rubber gloves

•

CLEANING SOLUTION

Kay-5

® Sanitizer/Cleaner, chlorinated alkaline product is approved for use as a

manual type cleaner or for use as a chlorinating sanitizer. Kay-5® is available in 1

oz. packets. Two, 1 oz. packets of Kay 5® mixed with 5 gallons of water, will

deliver the appropriate cleaner concentration.

PREPARATION:

Prepare sanitizing solution by adding two, 1 oz. packets of Kay-5® to 5 gallons of

potable water (not greater than 100°F) in a clean 5 gallon bucket. This produces a

100 PPM chlorine solution. Stir to ensure Kay-5

®

crystals are completely

dissolved.

CAUTION: Chlorinated detergents are corrosive. Wear rubber gloves and safety

goggles while performing all cleaning and sanitation procedures.

Note:

If a chlorinated sanitizer/cleaner other than Kay-5® is used, follow the manufac-

turer’s instructions for proper dilution to produce 100 PPM Sanitizer/Cleaner solution.

DO NOT USE BLEACH. Bleach is abrasive and harsh on the numerous plastic

components in our dispensing systems. We have confirmed that using a buff-

ered chlorinated detergent and following the prescribed procedures ensures

optimum sanitation and maintenance of dispensing equipment. This will limit

sanitizer odor/off-taste carryover that could be perceived as a hazard

CLEANING THE SHEATHING

Materials Required:

Cleaning Solution (see CLEANING SOLUTION, above)

Flexible soft plastic bristle brush

Clean, dry Bar Towel

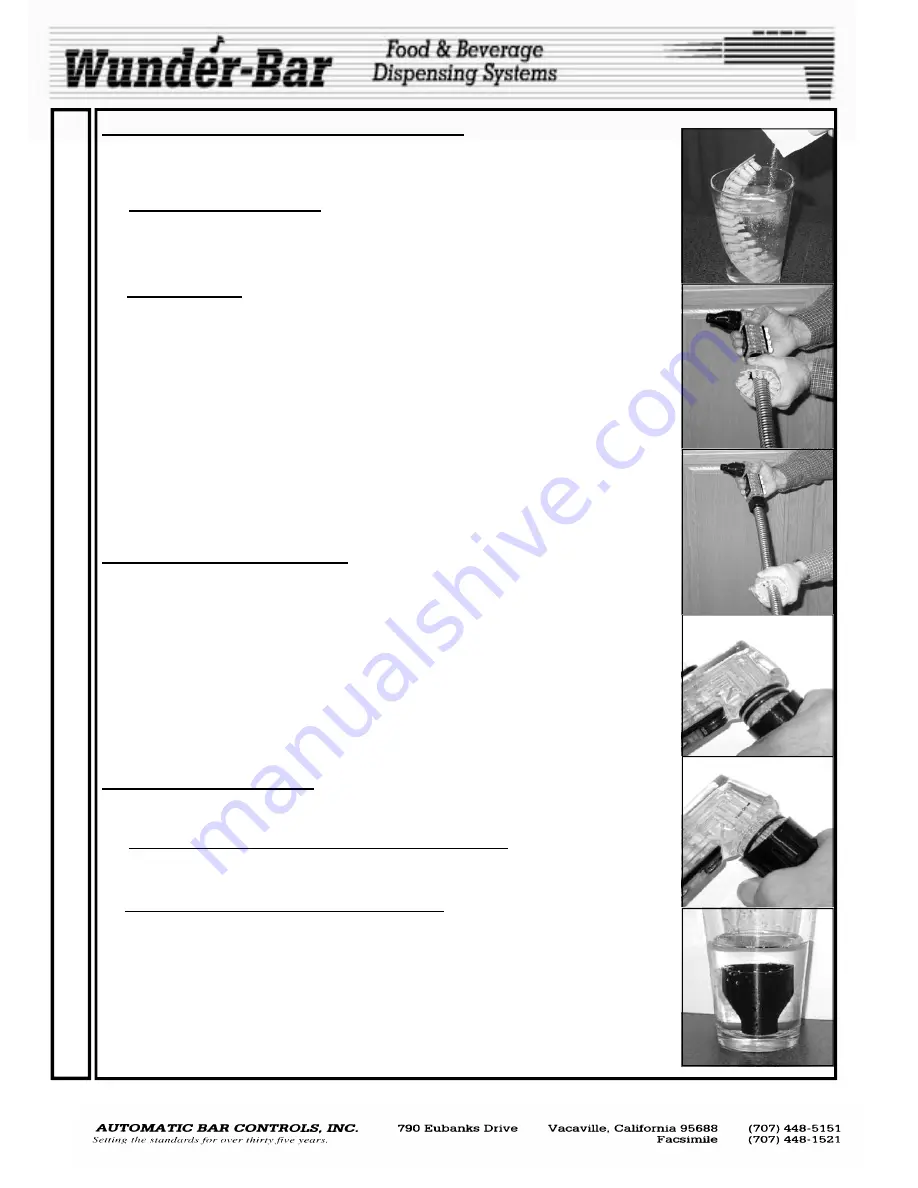

1.

Immerse the Brush in Cleaning Solution as shown in

Fig.1

.

2.

Wrap the brush around the sheathing at the Heel end (

Fig.2

). Move the brush up and down

the entire length of the Sheathing, from Heel to Manifold (

Fig.3

), a minimum of 6 times.

3.

Immerse the Brush in the Cleaning Solution. Rotate the Sheathing Brush 1/2 turn. Move

the Brush up and down the entire length of the Sheathing 6 more times.

4.

Immerse the Sheathing Brush in the Cleaning Solution. Rotate the Sheathing Brush an

other 1/2 turn. Move the Sheathing Brush up and down the entire length of the Sheathing

a minimum of 6 more times. Dry the entire length of the Sheathing with a clean bar towel.

CLEANING THE NOZZLE

Material Required:

Cup of Cleaning Solution (see

CLEANING SOLUTION

above)

1a.

SERIES II NOZZLE REMOVAL: (Compression Fit, two O-rings) (

Fig.4

)

Grasp the nozzle and twist back and forth while pulling the nozzle away from the

handle. If he nozzle is difficult to remove, immerse nozzle end of the handle in a cup of

carbonated water for five minutes before attempting removal again.

1b.

SERIES 2.5 and SERIES III: (Twist-Lock, one O-ring) (

Fig.5

)

Grasp and twist the nozzle counterclockwise to unscrew the nozzle from the Handle.

If the nozzle is difficult to remove, immerse nozzle end of the handle in a cup of

carbonated water for five minutes before attempting removal again.

2.

Remove nozzle and place in cup of cleaning solution (see CLEANING SOLUTION above)

for 2 minutes. Immerse a clean brush in the sanitizer solution. Scrub nozzle and diffuser

with a clean brush until any and all buildup is removed.

3.

Remove nozzle from sanitizer solution. Allow nozzle and diffuser to air dry.

4.

Reinstall nozzle onto diffuser.

5.

Dispense a beverage to confirm proper operation.

Fig.5

Fig.1

Fig.4

Fig.2

Fig.6

Fig.3

MARK 4 MANUAL

www.wunderbar.com

Содержание Mark 4

Страница 15: ...15 15 www wunderbar com ...

Страница 16: ...16 16 www wunderbar com ...

Страница 17: ...17 17 www wunderbar com FR 73 ...

Страница 18: ...18 18 www wunderbar com ...

Страница 19: ...19 20 www wunderbar com ...

Страница 20: ...20 19 www wunderbar com ...

Страница 21: ...21 21 www wunderbar com ...

Страница 22: ...22 www wunderbar com 22 FR 73 ...

Страница 23: ...23 23 www wunderbar com ...

Страница 24: ...24 24 www wunderbar com ...

Страница 25: ...25 25 www wunderbar com ...

Страница 26: ...26 26 www wunderbar com ...