WARNING

• All 8504 models contain four (4) LED heads. At a close distance, never look directly at the heads when

the power supply is turned on. Momentary blindness and/or permanent eye damage could occur.

• The power supply produces LOW VOLTAGE. Never touch or remove any of the LED heads while in

operation. Wait no less than 5 minutes after disconnecting the power supply from it’s power source

to attempt to handle LED heads or troubleshoot.

• DO NOT connect the power supply to the vehicle’s battery or any other power source until ALL LED heads

are mounted and wired to power supply.

FAILURE TO FOLLOW ALL SAFETY WARNINGS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO

PRODUCT, VEHICLE OR COULD CAUSE SERIOUS INJURY TO YOU AND

PASSENGERS!

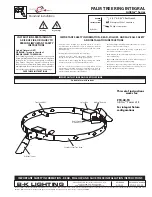

INSTALLATION OF POWER SUPPLY Fig. A

CAUTION

The power supply is NOT waterproof and must be mounted in a dry location

inside vehicle. The power supply should NEVER be exposed to weather

conditions such as rain, snow, water and etc. The power supply should be

mounted in a well-ventilated location. Never mount the power supply in the

vehicle’s engine compartment near a heater duct or close to the engine

components that will get hot.

IMPORTANT

The power supply should be mounted on a metal surface to help prevent radio

interference and to act as a heat sink. Doing such will reduce heat from the power supply protecting the

electronic components. Make sure that the mounting surface does not get hot from normal vehicle operation.

1. Place the power supply on the mounting surface. Using the mounting bracket as a template, mark the four

hole locations onto the mounting surface and drill to size using a 1/8” drill.

2. The installer must carefully inspect both sides of the selected mounting location to ensure that there are no

components, wires and or any other vehicle part that could be damaged by the drilling.

3. Position the power supply to the mounting surface and secure using the sheet metal screws provided.

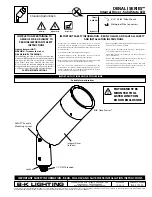

INSTALLATION OF THE LED HEADS INTO THE HEADLIGHT and TAILLIGHT ASSEMBLIES

Fig. B

IMPORTANT

• The LED heads are going to share the same reflector and lens as the headlight and taillight. Before drilling

any hole into the light assembly you must make sure that the

position of the LED head will not interfere with the operation or

visibility of the vehicles original equipment light.

• The LED head must have a minimum of one (1) inch of open

space from the OEM factory bulb.

• Never install the LED head directly above the OEM factory

bulb.

• Before drilling the hole for the LED head, the installer should

remove the OEM factory light assembly and reflector.

4. Select a position in the headlight or taillight assembly that is

flat to ensure a good watertight seal with the rubber gasket

that is placed between the LED head and the light assembly.

5. Using a 1” hole saw, cut a hole into the light assembly in the selected location and de-burr hole.

6. Install the LED head into light assembly.

Fig. A

Fig. B

1/8”

SCREW