43

3064300_201703

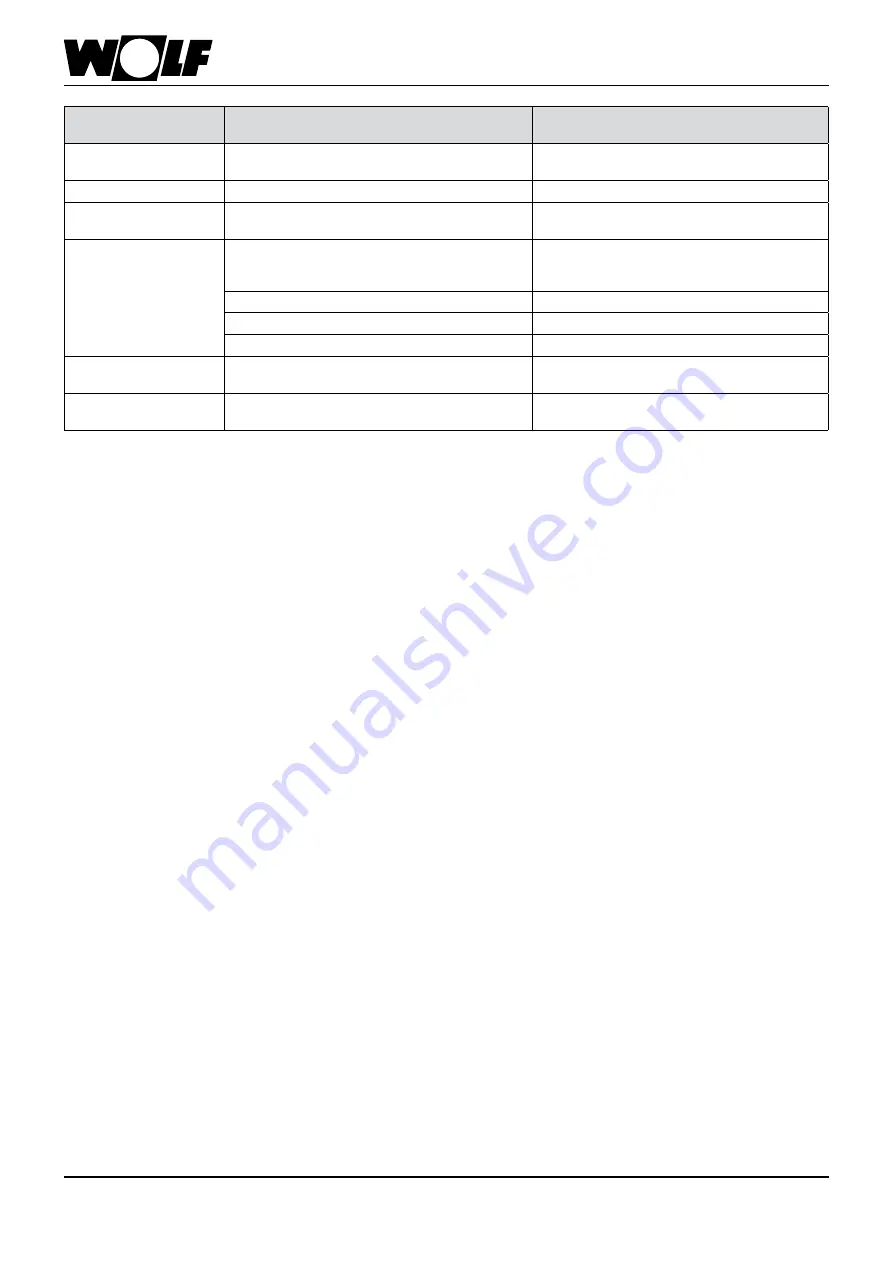

Fault

Cause

Remedy

Leak in floor-standing

DHW cylinder

Flange leaking

Tighten bolts to a torque of 20-25 Nm, working

diagonally; replace gasket

Pipe connections leaking

Re-seal the connections

Heat-up time too long

Heating water temperature too low (measure at

floorstanding cylinder flow, not at heat generator)

Increase temperature (adjust controller)

Heating water volume too low (resulting in a wide

spread, i.e. return temperature too low)

Larger pump

Pay attention to back pressure from parallel

heating circuits

Internal indirect coil not vented

Vent several times with the pump switched off

Build up of scale on heating surface

Descale heating surface

Cylinder sensor not in sensor well

Check position of cylinder sensor

DHW temperature too low

Thermostat switches off too early

Thermostat or control unit

Adjust thermostat or increase set temperature

at control unit

Return temperature too low (e.g. spread too wide) Larger charging pump or increase speed of pump

in the appliance via the control unit

37. Troubleshooting – DHW cylinders

CEW-1-200, CEW-2-200, SEW-1, SEM-1W