Commissioning and operation

INTORQ | BA 14.0201 | 04/2016

26

6.1.2

Microswitch

These spring-applied brakes are equipped with two microswitches. One microswitch is for release monitoring

and one is for wear monitoring (see Figure 1). The microswitches are either connected in series (NC con-

tacts, black and grey wire strands) or in parallel as NO contacts (black and blue wire strands).

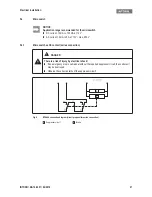

Checking the release control

Fig. 9

Release monitoring

Check the setting of the microswitch for release monitoring using a feeler gauge with thickness "Y

max

and

Y

min

" between hexagon head cap screw (1) and microswitch tappet (2).

NOTICE

Each of the two microswitches should be checked for correct operation when the brake is

applied (not actuated). During the check, the other microswitch must not be actuated.

NOTICE

The brake is deenergized, the transport screws are removed.

1

Hexagon head screw

2

Microswitch tappet

Feeler gauge thickness

NC contact

N/O contact

Y

max.

= s

L

- 0.10

Switch open

Switch closed

Y

min.

= s

L

- 0.25

Switch closed

Switch open

Commissioning and operation

INTORQ | BA 14.0201 | 04/2016

27

Checking the wear monitoring

Fig. 10

Wear monitoring

1. Measure the air gap "s

L

" between brake disc (1) and friction linings (2) using a feeler gauge (with brake

energized, refer to

25).

2. Switch off the voltage supply

3. Calculate the thickness "X" of the feeler gauge: 0.75 - "s

L

" = X

4. Insert a feeler gauge of thickness "X" between microswitch tappet (3) and friction lining carrier (2) (with

brake deenergized). The feeler gauge must lie flat. The switch must be actuated.

5. Use a feeler gauge with a thickness lower by 0.05 mm and check if the switch remains in the original

switch position. The feeler gauge must lie flat.

6.1.3

Test that the manual release functions

1

Brake disc

2

Friction lining

3

Microswitch tappet

NOTICE

This operational test is to be carried out additionally!

DANGER

The drive system must be free of loads. The motor must not run!

NOTICE

When the maximum permissible working air gap "s

Lmax

" (

14) is exceeded during brake

operation, the braking torque is considerably reduced by the manual release. Proper brake

function is no longer ensured.

Содержание WSG-25

Страница 82: ...Notes INTORQ BA 14 0201 04 2016 36 Notes...