Malfunctions

40 English

9 Malfunctions

This chapter explains the remedies in case of malfunctions. The causes and remedies have been specified

in the tables. Contact the Winterhalter service engineer if you cannot eliminate the error yourself.

Danger

DANGER! Danger of life due to components that are energised!

Do not open any machine covers or machine parts if it requires tools. There is danger of shock.

Let a Winterhalter service engineer carry out work on the electrical system. The machine must

first be disconnected from the mains.

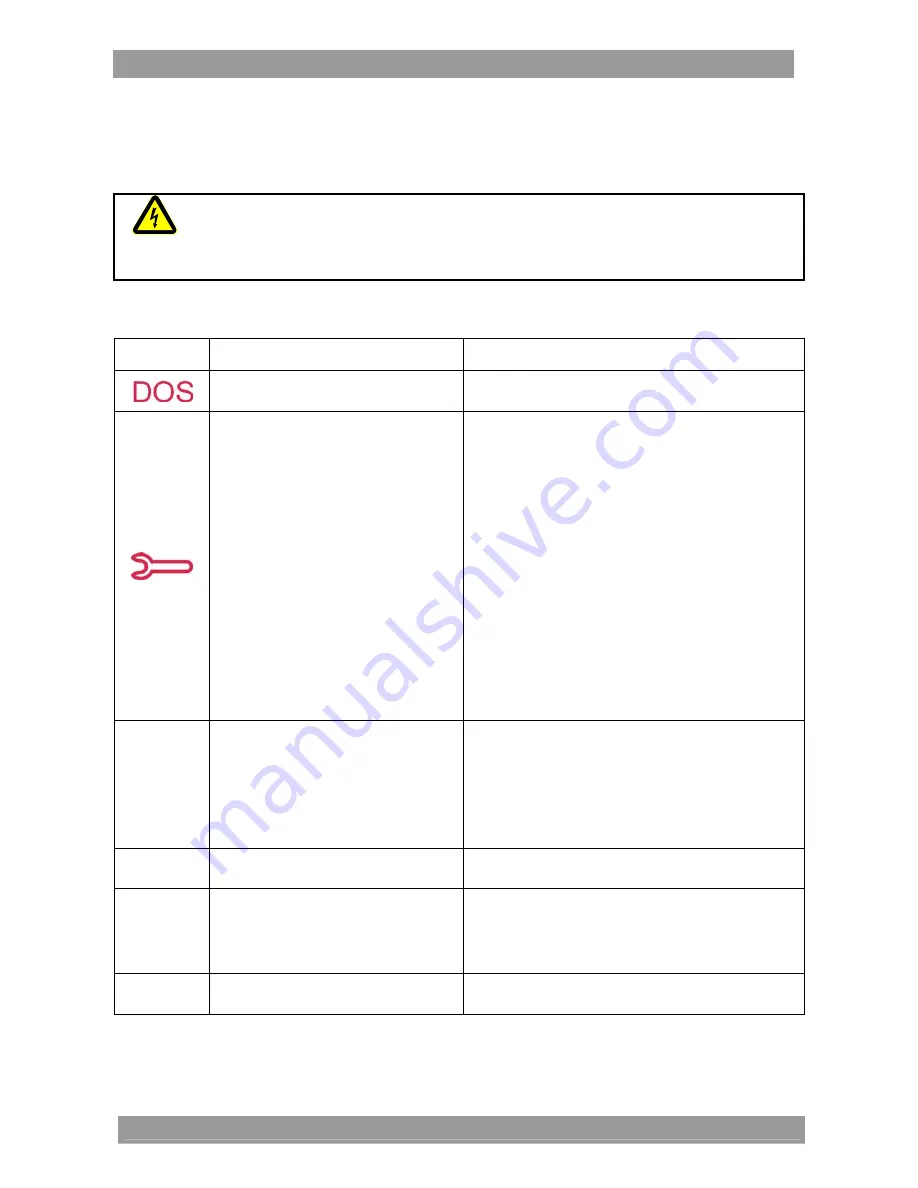

9.1 Malfunctions; display on the operating panel

Display

Meaning

Remedy

Insufficient detergent or rinse aid

Refill the detergent or rinse aid

Error message

Switch off the machine

An error code is displayed on the operating

panel

If Err 4, Err 5, Err 7-Err 10, Err 15 or Err 17-Err 18

is displayed:

Check whether the water shut-off valve is open

Switch on the machine again

If there is an error message:

Disconnect the machine from the mains and

close the water shut-off valve

Forward the error message to the Winterhalter

service engineer

If another error code is displayed:

In this table, check what the error code means

then follow the notes

Err 1

Err 12

Err 13

If error code

Err 1, Err 12

or

Err 13

is

displayed, it means that there is a

machine malfunction due to which the

machine automatically switches off

and can no longer be switched on.

Forward the error message to the Winterhalter

service engineer

Err 6

Machine-internal error or water supply

blocked

Inform the Winterhalter Customer Service or get

the blockage rectified.

Err 21

If the error code

Err 21

is displayed

when the machine is switched off, it

means that the water level in the

machine was too high. Water was thus

pumped off.

Close the water shut-off valve so that water no

longer flows into the machine

Forward the error message to the Winterhalter

service engineer

Err 23

Machine-internal error

Forward the error message to the Winterhalter

service engineer