11

Operations

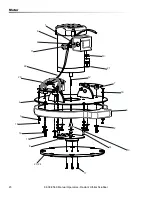

Brush Installation

Put the machine base in an upright position, sitting on

the foot of the bumper.

Remove the driver plate by removing the four counter-

sink screws in the center of the plate using an electric

screwdriver.

It is important to only use a Number 3 Phillips head

screwdriver bit. Smaller bit sizes can damage the screw

heads and leave sharp edges, which can tear or snag

the pads. Damaged screws can cause further damage.

Mount the brush with the same countersink screws

used for mounting the driver plates.

NOTE: Tighten the screws sufficiently to avoid

disengagement of the brush from the machine during

operation

To avoid stripping the screws do not over tighten. An

electric screwdriver with a clutch will ensure that

stripping will not occur.

Attaching and Removing the Driver Plates

Put the machine base in an upright position, sitting on

the foot of the bumper. Remove the driver plate by

removing the four countersink screws in the center of

the plate using an electric screwdriver.

8.638-856.0 Manual Operators - Radiant Orbital Scrubber

Содержание 1.005-297.0

Страница 1: ...8 638 856 0 B 06 13 17 RADIANT ORBITAL SCRUBBER Operator s Manual Floor Machine MODELS 1 005 297 0...

Страница 18: ...17 Notes 8 638 856 0 Manual Operators Radiant Orbital Scrubber...

Страница 19: ...18 Parts Parts RADIANT ORBITAL SCRUBBER 1 005 297 0 8 638 856 0 Manual Operators Radiant Orbital Scrubber...

Страница 22: ...21 Tank 8 638 856 0 Manual Operators Radiant Orbital Scrubber 5 8 4 14 6 13 9 3 1 12 2 13 10 11 12 7...

Страница 28: ...27 Spray Handle 8 638 856 0 Manual Operators Radiant Orbital Scrubber 1 2 11 3 10 4 5 5 6 6 12 12 13 13 7 8 9...

Страница 32: ...8 638 856 0 Printed in U S A...