3180-10

6

60706-238

GASOLINE

When using gasoline, always use fresh, clean,

unleaded fuel. This engine is certifi ed to operate on

unleaded gasoline with a minimum octane rating of

86 or higher. Gasoline containing no more than 10%

ethanol is acceptable.

CAUTION: EQUIPMENT DAMAGE

Do not use unapproved gasoline, such as E15 or

E85. Do not mix oil in the gasoline. Use of unap-

proved fuels will damage the engine components

and void the engine warranty.

Use of fuels with content of ethanol greater than

shown above may cause starting and/or perfor-

mance problems. Always ensure that the fuel is

clean and free of all impurities.

WARNING: FIRE DANGER

Gasoline and its fumes are VERY explosive when

proper precautions are not taken.

Never use gasoline that has been stored for an ex-

tended period of time as the fuel will lose its volatile

properties and you will be left with varnish residue.

The varnish like substance will clog the carburetor

and will not burn properly.

The use of fuel additives, such as STA-BIL, or an

equivalent will minimize the formation of fuel gum

deposits. If a unit has been out of operation for an

extended period of time, it is best to drain old fuel

from the engine and replace with fresh fuel before

attempting to start.

NG FUEL INSTALLATION

The information in this instruction is offered to assist

you in providing the proper Natural Gas (NG) fuel

supply for your engine. This information is only pro-

vided to advise you of the engine’s requirements and

the decisions you must make. In no case should this

information be interpreted to confl ict with any local,

state or national code. If in doubt, always follow local

codes.

DANGER: FIRE - PERSONAL INJURY -

All fuel lines must be installed by a qualifi ed fuel

supplier

.

The fuel source should be as close as possible to

the outdoor operating location. This will reduce the

installation cost of fuel runs. Connect the fuel supply

line to the inlet of the fuel demand regulator on the

unit using a locally approved fl exible fuel line (see

table for recommended line size).

The pressure

supplied to the demand regulator must be 4 TO 6

OUNCES or 7 to 11 INCHES W.C. (water column).

The primary regulator at the fuel supply must be

capable of delivering the proper volume of fuel at this

pressure.

Have your local fuel supplier install a protected fuel

connection at the outside operating location. They

should also install a lockable fuel shut off valve at the

connection point. An approved fl exible fuel line must

be installed between the engine generator set and

the supply line.

DANGER: FIRE - PERSONAL INJURY -

The NG fuel supply line must always be shut off

when the engine is not running. Failure to do so may

allow fuel to leak at the unit.

INSTALLING THE FUEL LINE

DANGER: PERSONAL INJURY

Units that are intended to be run unattended MUST

have an electric fuel solenoid installed. This solenoid

MUST be wired to AUTOMATICALLY turn off the fuel

whenever the engine stops.

Unit location will determine the size of fuel line that

is required to supply the engine with a constant fuel

pressure. Refer to the tables below for fuel line size,

and recommended tank size. The line size from the

table below applies to the distance from the second

regulator to the demand regulator.

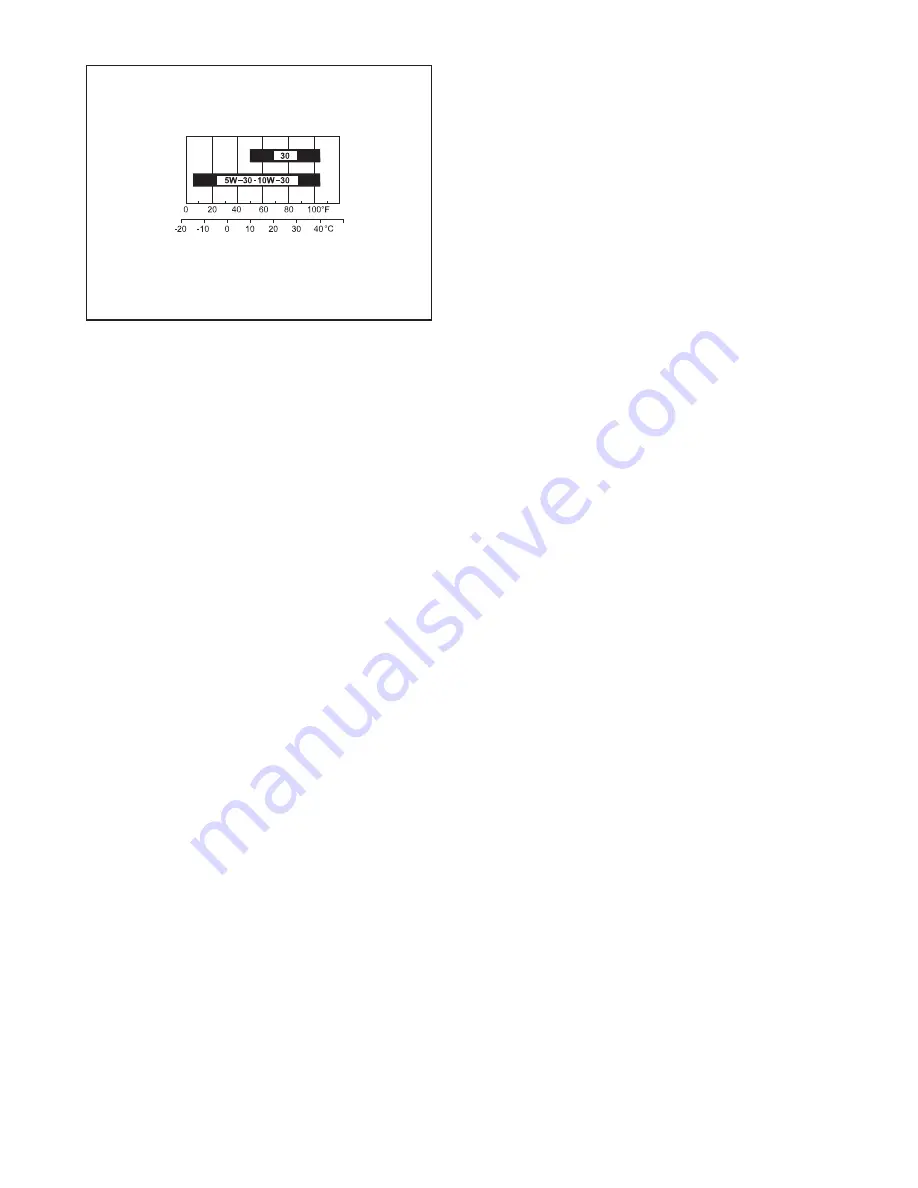

AMBIENT TEMPERATURE

Use 4-stroke motor oil that meets or exceeds the requirements for

API service classification SJ or later (or equivalent). Always check

the API service label on the oil container to be sure it includes the

letters SJ or later (or equivalent).

SAE 10W-30 is recommended for general use. Other viscosities

shown in the chart may be used when the average temperature in

your area is within the indicated range.