3180-10

12

60706-238

OPERATING SPEED

The engine-generator must be run at the correct

speed in order to produce the proper electrical volt-

age and frequency.

CAUTION: EQUIPMENT DAMAGE

The output voltage should be checked to ensure

the generator is working properly prior to connecting

a load to the generator. Failure to do so could result

in damage to equipment plugged into the unit and

possible injury to the individual.

All engines have a tendency to slow down when a

load is applied. When the electrical load is con-

nected to the generator, the engine is more heavily

loaded, and as a result the speed drops slightly.

This slight decrease in speed, together with the

voltage drop within the generator itself, results in a

slightly lower voltage when the generator is loaded

to its full capacity than when running no load. The

slight variation in speed also affects the frequency of

the output current. This frequency variation has no

appreciable effect in the operation of motors, lights

and most appliances. However, electronic equip-

ment and clocks will be affected if correct RPM is

not maintained. See Load vs. Output chart.

Although individual units and models vary slightly,

the normal voltage and frequency of the engine-gen-

erator described in this manual are approximately as

follows, under varying loads:

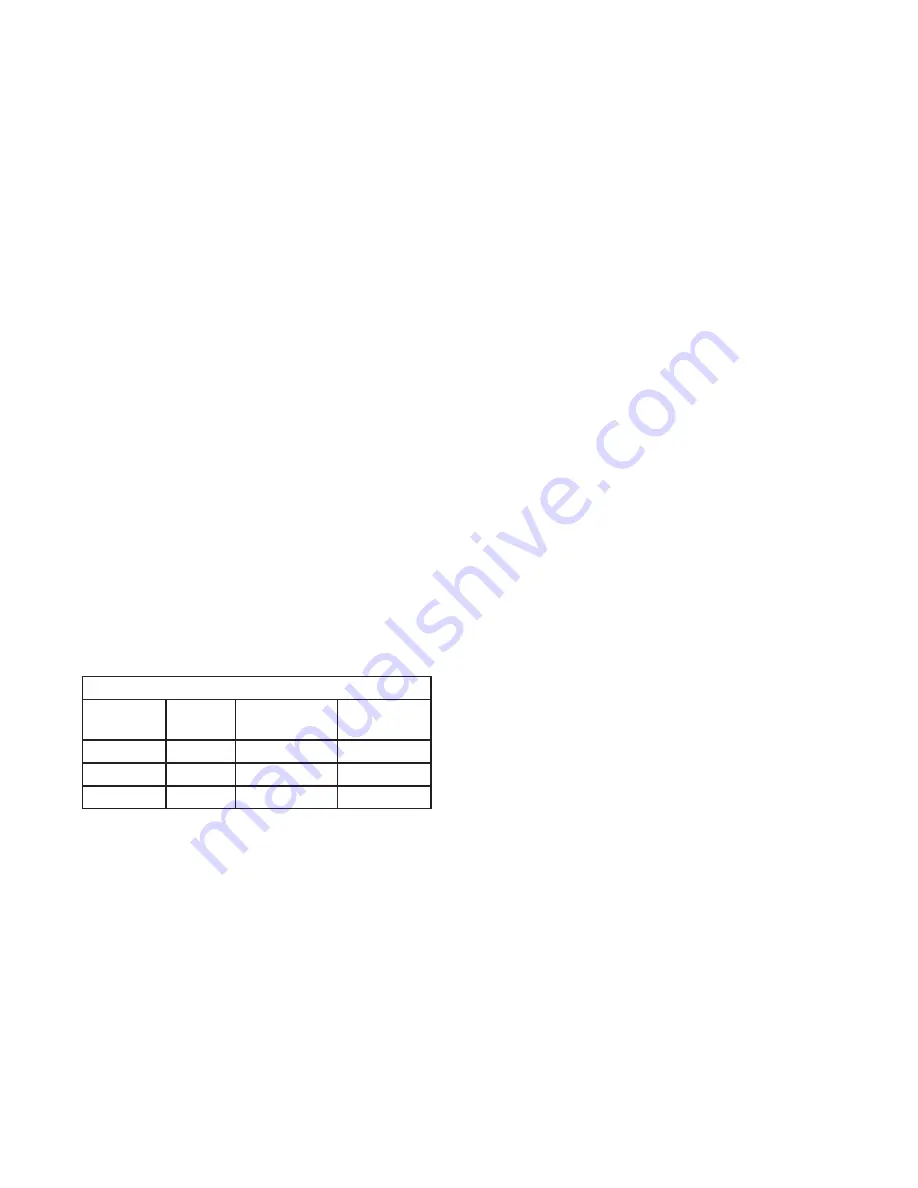

LOAD VS. OUTPUT

Generator

Load

Speed

(RPM)

Frequency

(Hz)

Voltage

None

3690

61.5

125V

Half

3600

60.0

120V

Full

3510

58.5

115V

The speed of the engine was carefully adjusted at

the factory so that the generator produces the prop-

er voltage and frequency. For normal usage, the

speed setting should not be changed. If the genera-

tor is being run continuously on a very light load, it is

often advisable to lower the operating speed slightly.

CAUTION: EQUIPMENT DAMAGE

SPEED ADJUSTMENTS SHOULD ONLY BE

MADE BY A QUALIFIED SERVICE TECH.

Whenever making any speed adjustments,

check the unit with a voltmeter and a frequency

meter or tachometer and be sure the voltage and

speed are correct.

Lower voltage may damage both the generator and

any load connected to it. Running the engine at ex-

cessively high speeds results in high voltage, which

may signifi cantly shorten the life of appliances being

used.

Output voltage should be checked periodically to

ensure continued proper operation of the generat-

ing plant and appliances. If the generator is not

equipped with a voltmeter, it can be checked with a

portable meter.

CONNECTING THE LOADS

Allow the engine to warm up for two or three minutes

before applying any load. This will allow the engine

to reach normal operating temperature and oil to cir-

culate throughout the engine. A short warm-up time

will permit the engine to work more effi ciently when

the load is applied and will reduce the wear in the

engine, extending its life.

Receptacles have been provided to allow loads to

be connected to the generator. The loads should

be added one at a time. If a large motor is being

started; or multiple motors are being started, they

should be started individually and the largest should

be started fi rst.

CAUTION: EQUIPMENT OVERLOAD

Keep the generator load within the generator and

receptacle nameplate rating. Overloading may cause

damage to the generator and/or the loads .

Most electric tools and appliances will have the volt-

age and amperage requirements on their individual

nameplates. When in doubt, consult the manufac-

turer or a local electrician. The nameplate amperage

rating for electric motors can be misleading. See

“Starting Electric Motors” in Unit Capabilities (page

4).

These engine-generator sets are inherently self regu-

lating based on engine speed. The engine governor

will automatically adjust itself to the load. No harm

to the generator will result if it is operated with no

load connected. Proper utilization of the receptacles

located on the control panel is necessary to prevent

damage to either the receptacles or the generator.

The generator is a limited source of electrical power,

therefore, pay special attention to the receptacle