Installation and operating instructions WILO Mather and Platt

–

Sump Pumps 27

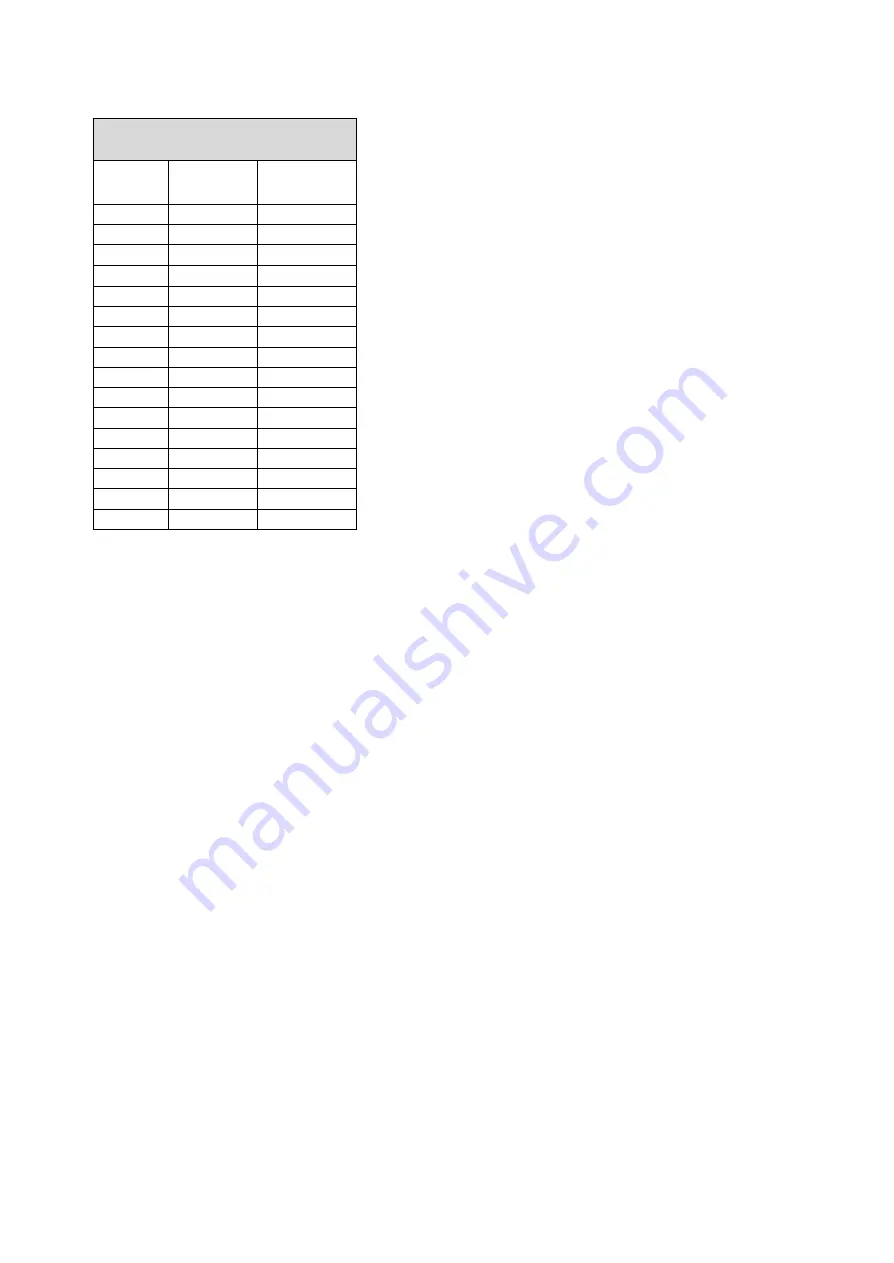

Recommended Tightening Torques for

fasteners (Nm)

Thread

Size

Material

Class 8.8

Material

Class 10.9

M4

3

4.3

M5

6

8.9

M6

10.3

15.1

M8

25

37

M10

50

74

M12

67

128

M14

139

205

M16

214

316

M20

431

615

M22

586

835

M24

745

1060

M27

1090

1560

M30

1480

2105

M33

2013

2865

M36

2586

3680

M39

3348

4760

10.2 Overhaul maintenance

•

After a long period of service, wear will occur in parts of the

pump, necessitating the renewal of a few components. Logbook

records will indicate wear as gradual deterioration of

performance is noticed. Once this is known, pumps should be

taken for overhaul. It is recommended that yearly stripping &

checking of wear & tear and clearances should be done and

overhauling where required.

•

If related pair of components show a marked degree of wear in

relation to the rest of the unit, then it may be sufficient to renew

only the heavily worn components. If the wear is uniform

throughout the pump, then all wearable components may

require renewal.

•

Measurements should be taken and recorded of all wearable

components at the first, and every subsequent overhaul period.

Reference to these records will enable an accurate assessment

of the rate of wear to be made, and a reasonably accurate

forecast regarding when a particular component may require

renewal can be made.

•

Information regarding original design dimensions and clearances

is furnished in data sheet. Any other information, if needed, can

be requested from Service Department, WILO Mather Platt. Such

requests must quote name plate number and type of the pump

in question.

The parts most likely to be affected are:

•

Impeller

•

Neck Rings

•

Sleeves

•

Stuffing Box Bush

•

Bearings

•

Coupling Bushes

Before commencing dismantling operations, ensure that the

following tools and tackles are available:

•

A crane / chain pulley block suitable for handling the weight

of pumping unit.

•

A selection of ring and open-ended spanners in Metric sizes.

•

Eyebolts in Metric sizes.

•

Cotton rope, wire rope and slings.

•

Hardwood and metal packing blocks.

•

Miscellaneous tools including a set of Allen keys, screw

drivers, files etc.

•

Extractor / puller for bearing and coupling.

•

The torque value to be set for a particular size of screw is

dependent upon:

•

Material of screw

•

Parent metal

•

Whether the screw is untreated or plated

•

Whether the screw is dry or lubricated

•

The depth of the thread

10.3 Disassembling the Pump

10.3.1 Disassembling the top Motor

•

Isolate the pump motor electrically

•

Isolate the pump system hydraulically

•

Clear the area of any equipment that might impede the free

lifting of the pump

•

Disconnect and remove the driving coupling

•

Disconnect the electrical supply cables from the motor

terminal block

•

Attach slings and lifting apparatus to the motor lifting

attachments

•

Remove the screws / bolts, or nuts, from the motor flange

and lift the motor off from the motor stool.

•

Support the motor on timber packing blocks with the

coupling hub clear off the ground

10.3.2 Removing pump from pit

•

Dismantle the discharge pipeline, delivery valves and non-

return valve from the delivery pipe.

•

Then remove the complete pump assembly along with

mounting plate away from the sump.

10.3.3 Disassembling of pump parts

•

Remove the coupling key & take off the coupling half from

top pump shaft.

•

Remove Adjusting ring from the shaft.

•

Dismantle the delivery pipe (TOP) from the casing.

•

Remove bearing cover, unscrew lock washer and remove

bearing cartridge along with bearing from top shaft.

•

Unscrew the fasteners and remove the motor stool

•

Remove casing from the bottom support pipe along with the

strainer.

•

No need to remove the strainer from casing unless it is to be

cleaned or replaced.

•

Remove the locking screw and unscrew the impeller nut

•

Remove the impeller

•

Unscrew the fasteners and remove the back cover along

with the bush bearing

•

Remove shaft sleeve from the shaft.

•

Remove intermediate assembly consists of the support

pipes and intermediate shafts and bearing brackets.

•

Remove muff coupling assembly

•

Remove the intermediate bracket/support pipe assembly

fasteners and remove top support pipe.

Содержание 4/5 TYPE 17

Страница 24: ...Installation and operating instructions WILO Mather and Platt Sump Pumps 24 ...

Страница 39: ...Installation and operating instructions WILO Mather and Platt Sump Pumps 39 NOTES ...

Страница 40: ...Installation and operating instructions WILO Mather and Platt Sump Pumps 40 NOTES ...

Страница 41: ...Installation and operating instructions WILO Mather and Platt Sump Pumps 41 NOTES ...