PMP-112 Multiposition

Oil Furnaces

–

Furnace Manual

18

11/13

5.

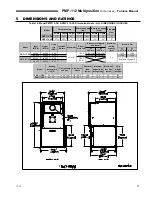

DIMENSIONS AND RATINGS (continued)

Table 11: Model PMP112-DD & PMP-112-VS Burner data

Model

Input

BTU/h

(*)

Firing

rate

USGPH

(*)

AFUE

(***)

Nozzle

(Delavan)

(**)

Pump

pressure

(PSIG)

(*)

Head

Low firing

rate baffle

Burner tube

insertion

length

(Inch)

Static

disc

ATC

Head/Air

setting

95,200

0.68

85.3%

0.60 - 60W

140

Yes (3708)

10/0

112,000

0.80

85.4%

0.65 - 60B

150

No

10/0

95,200

0.68

85.3% ‡ 0.60 - 60W

140

Yes (3708)

10/0

112,000

0.80

85.4% ‡

0.65 - 60B

150

No

10/0

Model

Input

BTU/h

(*)

Firing

rate

USGPH

(*)

AFUE

(***)

Nozzle

(Delavan)

(**)

Pump

pressure

(PSIG)

(*)

Head

Low firing

rate baffle

Burner tube

insertion

length

(Inch)

ATC

Head/Air

setting

95,200

0.68

85.8%

0.60 - 60A

130

No

3,5

112,000

0.80

85.3%

0.70 - 60A

130

No

2,5

95,200

0.68

85.8% ‡

0.60 - 60A

130

No

3,5

112,000

0.80

85.3% ‡

0.70 - 60A

130

No

2,5

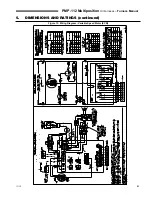

BECKET BURNER; MODEL AFG (Chimney)

BECKET BURNER; MODEL NX (Chimney or DV)

2 - Slot

L2

1 3/4"

6 - Slot

LQ

1 3/4"

3 3/8 U

AFG70MQSS

PMP112-DD

PMP-112-VS

PMP112-DD

PMP-112-VS

NX56LQ

Model

Input

BTU/h

(*)

Firing

rate

USGPH

(*)

AFUE

(***)

Nozzle

(Delavan)

(**)

Pump

pressure

(PSIG)

(*)

Burner

tube

insertion

length

(Inch)

Combustion air

adjustment

(Turbulator

/Damper)

95,200

0.68

85.8%

0.60 - 70A

130

1/2,6

112,000

0.80

85.4%

0.70 - 70A

130

2/3,1

95,200

0.68

85.8% ‡

0.60 - 70A

130

1/2,6

112,000

0.80

85.4% ‡

0.70 - 70A

130

2/3,1

Model

Input

BTU/h

(*)

Firing

rate

USGPH

(*)

AFUE

(***)

Nozzle

(Danfoss)

(**)

Pump

pressure

(PSIG)

(*)

Burner

tube

insertion

length

(Inch)

Combustion air

adjustment

(Head/Air)

95,200

0.68

85.2%

0.55 - 70A

145

,60 / ,65 - 18%

112,000

0.80

85.3%

0.65 - 70A

165

0,75 - 21%

95,200

0.68

85.2% ‡

0.55 - 70A

145

,60 / ,65 - 15%

112,000

0.80

85.3% ‡

0.65 - 70A

165

,60 / ,65 - 30%

RIELLO BURNER; MODEL 40-F3 (Chimney)

PMP112-DD

PMP-112-VS

2 3/4"

CARLIN BURNER; MODEL EZ-LF

PMP112-DD

PMP-112-VS

2 3/4"

C US

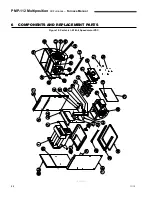

PMP furnaces are CSA

design certified for installation

on combustible flooring.

‡=

* INPUT & OUTPUT ADJUSTMENT

- Pump pressure can be adjusted to maintain proper firing rate.

- Increase pump pressure if flue gases temperature are under 400°F.

- Adjust the total flue gas temperature between 400°F and 575°F (330°F and 505°F) net approximately)

** Default Installed Nozzle in bold characters.

*** AFUE

values established after minimum 20 hours of operation.