Ku nst sto ffschweißtec hni k

Equipment care / maintenance / repair

Chapter 7

02.08.2011

Working Instructions WIDOS 4900 CNC 3.5

Page 42 of 68

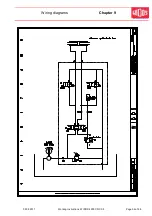

7.5. Venting the hydraulic cylinders

•

Venting the hydraulic cylinder

is not required

if

•

the hoses have been disconnected from the quick-action couplings at the control unit

because the remaining oil in the hose is being kept by valves and for this reason no air

can enter.

•

The hydraulic cylinder

must be vented

if

•

there has been too less oil in the tank and air has been attracted

•

there were leaky parts in the hoses or in the connections

•

the hoses were unscrewed from the basic machine.

•

Eliminate the cause of the air entrance.

•

Switch the machine on, legitimate with the card, then the main menu appears.

With buttons <+> and <->, the machine can be opened or closed.

•

Press button <-> and open the machine completely.

•

First unscrew the lower vent screw (Z1) for closing (lefthand side).

•

Connect the transparent venting hose and insert it in the collecting vessel.

•

Close by pressing button <+> until there is no more air visible in the venting hose.

•

Tighten again the vent screw (Z1).

•

Press button <+> and close the machine completely.

•

Then unscrew the lower vent screw (A1) for opening (righthand side).

•

Connect the transparent venting hose and insert it in the collecting vessel.

•

Open by pressing button <-> until there is no more air visible in the venting hose.

•

Tighten again the vent screw (A1).

•

When the venting procedure at the lower vent screws is finished, repeat the same at the

upper vent screw (Z2) for closing (lefthand side), and the upper vent screw (A2) for opening

(righthand side).

The lower vent screws always have to be vented at first because there is a direct

connection between the upper and the lower cylinders.

•

If air remains in the lower cylinder, it will ascend in the upper cylinder when

pressure is applied.

There must always be enough oil in the tank (see chapter 7.4).

Z2

A2

Z1

A1