160/180/200/250A MMA AC WELDING MACHINE ENG

OPERATING INSTRUCTIONS

Note:

Before using the welding machine, read the instruction manual carefully.

1. Intended use

This welding machine is made with traditional technology. It is intended for use for welding steel, stainless

steel.

2. Working environment

Under comparative dry environment, the environment temperature should be between -10

0

C and +40

0

C,

avoid working in the sun or rain, avoid working in the environment where there is much dust or corrosive

gas.

3.Power requirements

This welding machine is designed to operate on a properly grounded 220-240V or 380-400V (only for

WD060116018, WD060116020, WD060116025) 50Hz or 60 Hz, single-phase alternating current power

source. It is recommended that an electrician verify the actual voltage at the receptacle.

Warning:

If the actual power source voltage is less than 198V / 342V (only for WD060116018,

WD060116020, WD060116025) or greater than 253V / 440V (only for WD060116018, WD060116020,

WD060116025). Do not operate this welding machine.

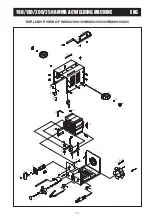

4. Installation

Note:

Only qualified persons should install, use or service this equipment. Protect yourself and others

from possible serious injury or death.

1) Connection of the power cable

a) This welding machine must be grounded while in use to protect the operator from electrical shock.

Make sure the power switch is off then connect your welding machine’s power cable to a properly

grounded.

Warning:

The green and yellow conductor in the cable is the grounding wire. Never connect the

green and yellow wire to a live terminal.

b) When you connect the cable of welding machine to 230V power source, brown wire must be

connected to live line terminal, and blue wire must be connected to zero line terminal (See Fig 1).

c) When you connect the cable of welding machine to 380V power source, brown and blue wire must be

connected to arbitrary two phase line terminal (

only for WD060116018, WD060116020, WD060116025)

(See Fig 2).

c) Use multimeter to check whether the voltage value varies in the given range.

2) Connection of output cable

a) Attach the work clamp to the workpiece, as close as possible to the area being welded. Clean with a

wire brush where necessary to ensure the connection is as clean as possible.

b) If the workpiece is too far away from the welding machine (Max distance is less than 5m), and the

secondary cable is too long, the section of the cable should be bigger to reduce the lower of the cable

voltage.

3) Checking

a) Whether the welding machine is connected to standard to earth.

b) Whether the power control screw is be adjusted to correct position.

11