Section VES-R00-20A

030-101639 Rev. B

R

8

0802IARB

13.

Attach cover (optional).

If the installed model contains a

cover, attach the cover at this time (model VESR-14 only).

3.5

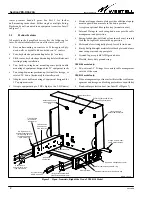

Mounting Equipment in the SwingRack

Customer-supplied equipment that is either 1 or 2 Rack Units

(RUs) high and designed for either 19" or 23" rack mounting

can be mounted on the SwingRack. If

two

1-RU-high units will

be mounted in the SwingRack, mount the first unit in the bot-

tom or lower position first (when the arms are in the down or

horizontal position). To mount 23" equipment, go to Paragraph

3.5.1. To mount 19" equipment, go to Paragraph 3.5.2

3.5.1

Mounting 23" Equipment in SwingRack

Equipment designed for 23" rack mounting mounts directly to

the ends of the swing-arms of the SwingRack. For 23" mount-

ings, the adapter ears are not needed, unless the race-way

and/or external-arm D-rings are to be installed in one RU.

- RACE-WAY OR D-RING MOUNTING NOTE -

The provided adapter ears serve three purposes: 1) They enable 19" equip-

ment mounting, 2) they enable mounting of the 19" race-way, and 3) they

enable mounting of the external D-rings. If the 23" equipment being

mounted in the SwingRack occupies only 1 RU, then the adapter ears can

be used in the second available RU position for one of the above three

items. If the 23" equipment being mounted in the SwingRack occupies 2

RUs, then the adapter ears, race-way, or D-rings cannot be used.

1.

Place arms in down position.

If the SwingRack’s arms are

in the up (closed) position, maintain contact with the arms

while sliding their latch-release knobs inward to disengage

the latches. Gently place the arms in the down (open or hor-

izontal) position.

2.

Determine proper equipment orientation.

Lift the equip-

ment to be mounted and, per company practice, determine

what orientation it will have when attached to the swing-

arms. Westell recommends that the front panel face the

center of the room, in the arm-down position (or face up,

in the arm-up position). For most equipment, this will place

important options, switches, LEDs, or jacks for testing and

monitoring purposes at the easiest position for installer ac-

cess and viewing.

3.

Align mounting holes and attach equipment to SwingRack

arms.

Align the correct mounting holes of the equipment

to be installed with the proper, bottom-most, threaded

holes at the end of each swing-down arm (see Figure 8). A

support plate helps to temporarily support the equipment

during this process. Attach the equipment (or the equip-

ment’s mounting ears) to the arms by inserting the provided

screws through the aligned holes and tightening the screws.

4.

Install external D-rings, if applicable.

Equipped with the

VESR-00 model are two, external-arm, 3" D-rings. If de-

sired, these D-rings can be installed at this time (see

Figure 3 or Figure 8 for the external D-ring mounting loca-

tion). As stated in the NOTE in Paragraph 3.5.1, if

2-RU-high equipment is installed, then the adapter ears

cannot be used to mount the D-rings. However, if space

permits (1 RU is available), attach the D-rings to the

center

set of holes

in the installed adapter ears: first mount the

adapter ears to the swing-arms, then mount the D-rings to

the ears using the provided hardware.

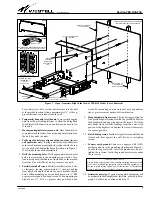

5.

Install race-way (slotted duct), if applicable.

For the

VESR-14 model only, if desired (and if one RU is avail-

able), the provided cable race-way can be installed at this

time in the top RU position, for cable management pur-

poses.

As stated in the NOTE in Paragraph 3.5.1, if the

equipment installed is 2 RUs high, then the race-way cannot

be used, as their mounting holes in the adapter ears are not

available.

Before installing the 19" wide race-way (see

Figure 7), first attach the adapter ears to the top RU posi-

tion at the ends of the swing-arms, using the provided

hardware. Then, to install the race-way, first orient the

race-way so the front cover faces the installer, or the center

of the room. Slide off the front cover. Locate the slots or

mounting holes on the back wall of the race-way (at both

ends) and align the slots with the corresponding inner-most

set of holes in the installed adapter ears, then attach the

race-way to the ears with the provided hardware. If cable

placement and routing will be performed at this time, post-

pone the re-attachment of the race-way’s front cover until

all cable installation and routing is complete.

6.

Install cable boots, if applicable.

The VESR-14 model is

shipped with two bend-radius cable protection boots (see

Inset B of Figure 7). Install the boots near the connector

end of the fiber cable by weaving and gently pressing the

cable into the slot provided in the boot, then slide the boot

up the cable as far as it will go, making it snug up against the

strain-relief of the connector. Repeat for each boot.

- CAUTION -

Always observe proper fiber cable bend radius requirements,

per company practice, and per cable and equipment

manufacturer instructions, to avoid fiber damage.

7.

Perform all cable routing and installer connections.

Tie-

down slots and factory-installed internal-arm D-rings are

provided in the SwingRack for convenient cable routing

and management. Some models also provide a 2-piece fi-

ber-management spool for cable routing or slack purposes,

and a flexible, orange, fiber-cable protection tube at the

back of the arm near the back plate. Fiber cables are typical-

ly routed first through the flexible orange tube, then looped

around the spool in the swing-arm (see Paragraph 2.2.2 if

greater spool slack or storage capacity is desired), routed

through the internal-arm D-rings, brought around the end

of the swing-arm, through any installed external-arm D-

ring and cable race-way, then attached to the appropriate

connector on the mounted equipment. If splicing of fiber

cables is desired at the SwingRack location, use the Westell

splice tray kit (which is mounted inside the swing-arm), per-

form all splicing per company practice, mount the tray in

the arm, and continue with cable routings and connections.

Use all of the aforementioned features to perform all cable

routings, management, connections, fiber splicing, and

cable slack management procedures, per company prac-

tice. Additional D-rings and cables are available (see

Table 3).