Section VES-R00-20A

030-101639 Rev. B

R

5

0802IARB

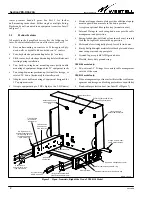

four ears. Always mount ears and equipment to the lowest RU

position first, for best equipment access and support. Each

adapter ear contains 6 holes (3 sets of two holes). When the

ears are positioned as shown in Figure 3, use the outside set of

holes to attach the ears to the end of the swing-arms. The 19"

equipment is then attached to ear’s inside set of holes. Mount-

ing screws are provided. The middle set of holes in each

adapter ear is designed to accept an external 3" D-ring, two of

which are provided with the VESR-00 model, one for each

swing-arm.

2.2

Fiber Management and Protection Features

Additional features are provided on or with the VESR-14 mod-

el to facilitate cable management. These features are described

in Paragraphs 2.2.1 through 2.2.4 below.

2.2.1

Protection Tube

To help protect fiber cables as they enter the arms of the Swing-

Rack, a short length of orange, flexible, fiber-cable protection

tube is factory-installed near the back of the right arm. After

equipment is mounted in the swing-arms, route and dress the

fiber connector cables. When routing cables, start near the low-

er right corner of the back plate, insert the fiber cable into the

free end of the flexible tube, feed it through the tube, then con-

tinue to route the cable through the entire length of the arm’s

inside channel to the end of the arm, using the spool, if desired

(described below), per company practice, and the D-rings. Per

company practice, and if desired, the free end of the flexible

protection tube can be loosely secured to the wall, to restrict ex-

cessive tube movement, with a customer-supplied tie strap and

saddle (see Figure 8).

2.2.2

Fiber Cable Management Spool

A 2-piece fiber cable management spool is factory-installed in-

side and near the back of the right swing-arm. After verifying

how much cable length is needed to reach the appropriate

equipment connectors, wrap any surplus lengths of each fiber

cable around this reel or spool, per company practice. If more

slack management capacity is desired, half of the spool can be

moved to the center of the swing-arm. This is accomplished by

removing the center D-ring, then detaching and moving the

front half of the 2-piece spool to the empty D-ring mounting

holes. In addition, the spool can be detached and moved to the

left or other arm, if desired.

2.2.3

Cable Race-way (Duct)

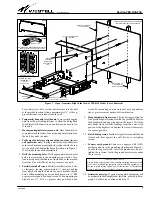

A protective cable race-way (slotted duct) is provided on the

VESR-14 model only. The race-way mounts to the inner set of

holes in the adapter ears, which are first mounted to the ends

of the swing-arms. The race-way can be used only when the

mounted equipment occupies only 1 RU, leaving the other RU

for the adapter ears and race-way. Numerous top and bottom

slotted holes are provided in the race-way for neat and orga-

nized cable management. After cables are routed through the

swing-arms, remove the cover of the race-way by sliding it off,

place the rear wall of the race-way against the adapter ears,

align the holes, then attach the race-way to the ears with the

provided hardware. Route cables through the race-way to the

slotted hole or tab closest to the equipment’s desired connec-

tor, and press on the race-way slot’s flexible tab to create space

to enable the cable to enter the slotted hole. When all cables are

connected or installed, replace the cover of the race-way by

snapping or pressing it in place, from the race-way’s front side

(or alternately, slide it in from the side).

2.2.4

Bend-Radius Protection Boots

Two, right-angle, bend-radius protection boots (see Inset B of

Figure 7) are provided to help protect fiber cables at their

cable-to-connector strain-relief junction. This junction can be

subject to sharp turns or bends, or frequent bending and twist-

ing during cable routing, installation, and equipment

maintenance and testing procedures. A properly installed boot

also protects the cable from any sharp edges it may contact (in-

cluding ducts or mounted equipment). Each boot provided

contains an open slot along its length that accepts the jacketed

fiber cable. Before mating fiber cable connectors to equipment

connectors, install any protection boots just under the cable’s

connector, per company practice. Gently press the cable into

the boot’s slot, then slide the boot up the cable to the connec-

tor’s strain-relief, as far as it will comfortably but firmly go,

until it is snug.

2.3

Other Features

2.3.1

Locking Cover

A removable but locking cover is provided on the VESR-14

model which both locks the swing-arms in the up position and

restricts hand and visual access to the front of the equipment

mounted in the SwingRack. Place the swing-arms in the up

position. Align the two tabs at the bottom of the locking cover

with the two corresponding slots in the top of the support plate,

then lower or set the cover into place at the front of the Swin-

gRack. Lock the cover with the provided key. To lock or unlock

the cover, insert the key and turn it 1/4-turn to rotate the lock’s

tab either into or out of the slot provided for it in the top flange

of the back plate.

2.3.2

External-Arm 3" D-Rings

On the VESR-00 model, two external-arm 3" D-rings are pro-

vided for additional cable management. These D-rings are

similar in function to the internal-arm D-rings, but mount out-

side the swing-arms, and are only 1 RU tall. These flexible but

sturdy D-rings have a split front edge which can be pressed to

allow ingress and egress of long cables, if desired. These D-

rings mount to the middle set of holes in the adapter ears, as

shown in Figure 8. The D-rings can be used only when 19"

equipment is mounted in the SwingRack, or if any 23" equip-

ment occupies only 1 RU, leaving the other RU for the adapter

ears and D-rings.

3.

INSTALLATION

Installation consists of inspecting the equipment for damages,

following proper safety precautions, gathering the required

tools and equipment, determining the mounting location, and

mounting the SwingRack. The following paragraphs provide de-

tailed instructions for performing these procedures.