7

2.20

Operation and System Optimization

2.21

High Pressure Operation

DUOSEAL two-stage pumps are designed to be most efficient when operated at or near their ultimate blanked off

pressure. The pump is designed to remove air from a vacuum system at atmospheric pressure to a deep vacuum.

When the pump is operated at elevated pressures up to about 10 Torr for long periods of time, the pump will run

hotter. At elevated ambient temperatures under these conditions, the thermal protection switch on single phase

motors may cut out. Use of an exhaust filter with coalescing element is required.

Leaky vacuum systems, too large a vacuum chamber for pump size or high gas loads to the vacuum systems

are causes for extended runs of the pump at elevated pressure. If you need additional information, please contact

Welch Vacuum at 847-676-8800, extension 1, for further information and precautions.

2.22

Principle of Gas Ballast

2.221 Effects of Unwanted Vapor

Systems which contain undesirable vapors cause difficulty both from the standpoint of attaining desirable ultimate

pressures as well as contamination of the lubricating medium. A vapor is defined as the gaseous form of any

substance which is usually a liquid or a solid. Water, oil and a mercury vapors are three of the more common

vapors encountered in typical vacuum systems. When such vapors exist in a system, the vapors or mixtures of

gas and vapor are subject to condensation within the pump; the precipitated liquid may thus ultimately dissolve

or become emulsified with the lubricating medium. This emulsion is recirculated to the chambers of the pump

where it is again volatilized causing increased pressure within the system.

2.222 Presence and Removal of Condensate

Condensation takes place particularly in the compression stroke of the backing or second stage of a two-stage

pump. The compression stroke is that portion of the cycle during which the gas drawn from the intake port is

compresses to the pressure necessary to expel it past the exhaust valve. Condensation takes place when the ratio

between the initial pressure and the end pressure of the compression is high, that is, when the mixture of vapor

and gas drawn from the intake port is compressed from a low pressure to high pressure. By adding air though the

gas ballast valve to the mixture of vapor and gas being compressed, the pressure required for delivery past the

exhaust valve is reached with a considerably smaller reduction of the volume of the mixture; this, depending upon

the amount of air added, condensation of the vapor is wither entirely avoided or substantial reduced.

2.223 Pump Function With Gas Ballast

In a pump functioning on a contaminated system and operating without the gas ballast, compression within the

stage takes place in the normal manner until the saturation pressure of the contaminating vapor contained within

the mixture of gas and vapor is reached. The saturation pressure of water vapor is that pressure and corresponding

temperature at which the dew point of the vapor is reached and condensation occurs. The saturation pressure of

water vapor at an ambient temperature of 20°C is 17.5 Torr, while at 60°C, the approximate operating temperature

of a pump, the saturation pressure is 149 Torr. The external side of the exhaust valve is subjected to atmospheric

pressure. Consequently a compressive force somewhat greater than atmospheric pressure is required to open the

valve and permit expulsion of the gas. Sometime during increased compression of the mixture of gas and vapors,

the saturation pressure of 149 Torr for the water vapor is reached and the vapor condenses. The condensate is

then allowed to emulsify with the oil which is recirculated within the pump stages this providing continued

contamination of the system.

2.224 Pump Function With Gas Ballast

On the other hand, when ballast air at atmospheric pressure is supplied to the compression stroke by means of the

gas ballast, the partial pressure of the unwanted vapor becomes a very small part of the total pressure of the

mixture of gas, vapor and newly supplied air. The vapor is thus prevented from reaching its saturation pressure

corresponding to the temperature of the pump and is finally expelled form the pump as a vapor.

2.225 Controlled Ballast Flow

Some degree of variation in ballast flow may be obtained by the amount of opening applied tot he gas ballast.

Two or more turns of the gas ballast are sufficient to open it wide. With the gas ballast open, the sound of the

exhaust is similar to that of a pump operating against a large leak. Because of the increased pressure introduced

into the compression stroke, the pump must work a little hard to function, thus resulting in an increased

operating temperature of approximately 8°C over a prolonged period of time. Tests have shown that continuous

and prolonged operation for several weeks under these conditions is not injurious to the pump.

CAUTION

Do not run this pump for prolonged periods of time at or above

10 Torr. The pump will overheat, excessive oil mist will be

emitted from the exhaust and the pump will eventually seize.

Содержание DUOSEAL 1399B-01

Страница 14: ...14 Section 6 DIMENSIONAL DRAWING ...

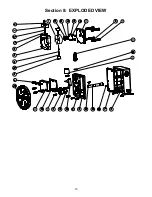

Страница 16: ...16 Section 8 EXPLODED VIEW ...