12

Section 4: TROUBLE-SHOOTING GUIDE

4.10

Poor Vacuum Readings

1. Disconnect vacuum pump from your vacuum system.

2. Obtain 1 gallon of DUOSEAL oil, 1 gallon or larger clear plastic container, clear drain hose

(1/4 inch ID by at least 2.5 feet long), rubber gloves, goggles, apron and pliers.

3. Carry out a forced oil flush (See Section 3.3b) if motor can turn pumping mechanism without

excessive noise. If pumping mechanism cannot be turned by motor, have pump sent into

factory repair center.

4. Check ultimate vacuum with thermocouple gauge. If reading is still unsatisfactory, consult with

Welch Technical Service after checking for leaks in your connections.

4.20

Noisy Pump

1. Locate noise source on your vacuum pump (motor, belt, pump).

2. If motor makes noise:

. Check for loose bolts on motor mount.

. Motor may need to be replaced

3. If belt makes noise:

. Pulley may be bent. If so, replace.

. Loose belt, tighten by loosening bolts on motor and moving motor away from pump until belt

exhibits a 1/2 inch deflection.

4. If pump makes noise: vanes may be sticking, carry out a forced oil flush.

5. If noise level is still unsatisfactory, consult with WELCH Technical Service at (847)676-8800, Ext. 1.

4.30

Excessive Oil Mist

1. Check oil level. Maintain the level between the two lines on the oil window during operation.

Too high a level will cause excess oil mist.

2. Determine the vacuum level in your system with a thermocouple gauge or manometer.

Be sure the pump is operating at a pressure of 10 Torr or lower for continuous operation.

3. A system leak(s) or degassing can cause excessive oil mist. Locate and seal the vacuum leaks.

High vapor loads may require a larger pump to compensate.

4. An oil eliminator can be installed for coalescing the oil mist from the exhaust gases. If an oil mist eliminator

is already installed, the element may need to be replaced if saturated with oil.

Open up oil mist eliminator and examine the element; replace if needed.

5. Check the oil condition for any visible change in color or consistency. Contaminants in the oil can

add to the amount of oil exhausted. Carry out a forced oil flush if contamination is discovered.

(See Section 3.3b.)

CAUTION

If not, discuss application with Welch Technical service before

proceedingto prevent oil from overheating and breaking down

resulting pump failing.

Содержание DUOSEAL 1399B-01

Страница 14: ...14 Section 6 DIMENSIONAL DRAWING ...

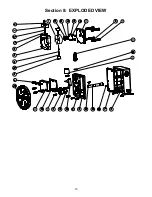

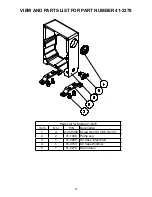

Страница 16: ...16 Section 8 EXPLODED VIEW ...