8

Section 2: PUMP FEATURES AND PRINCIPLES OF OPERATION

2.1 General Description

The Model 8890 Vacuum Pump is a two-stage, direct-drive gerotor pump featuring:

a. Capacity of 28 Liters/Minute (1 CFM).

b. Ultimate pressure of 0.1 mm Hg (100 microns)

c. Intake isolation valve available on certain models

d. Continuous operation at intake pressures from 100 microns too atmospheric.

For clarity, the modular vacuum pump assembly is referred to as the pump in this section.

2.2 Principles of Vacuum Pump Operation

The main purpose of a vacuum pump is to reduce the pressure in a vessel or a closed system. The degree of

pressure reduction is dependent upon the requirements of the application and the type of vacuum pump employed.

Mechanical, rotary, oil-sealed pump operation is described in this section because of its similarities to the

pumping action of this gerotor gear pump.

Pressure reduction in a closed system is accomplished by repeatedly removing a portion of the original volume of

gas contained in the system. Removal is performed by the action of the rotating elements of the pump which

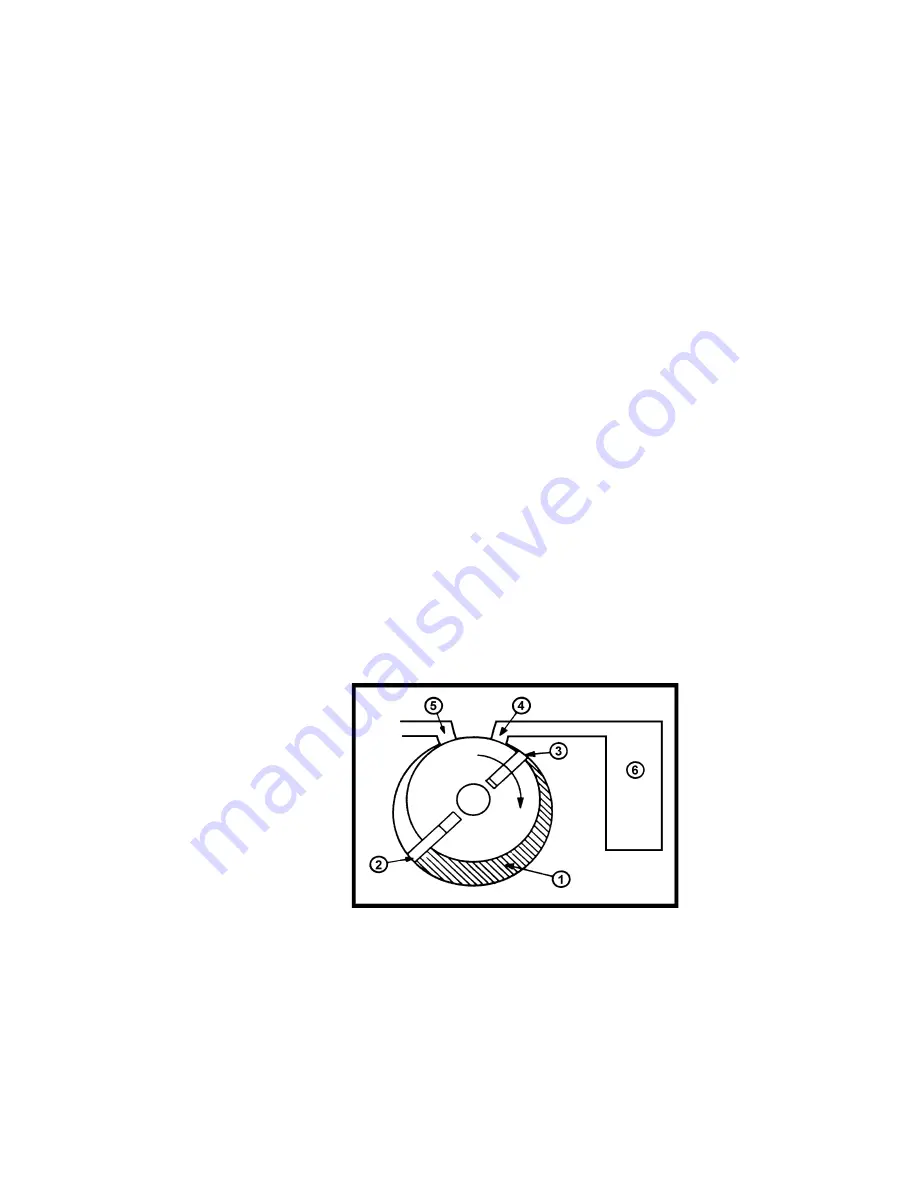

cause a given space to be successively enlarged and diminished. Figure 2-1 illustrates a section through a typical

stage of a rotary vane pump. Note that this figure is not intended to illustrate the internal components of a gerotor

pump such as the Model 8890; its purpose is to illustrate the general operating principles of vacuum pumps.

The rotary action of the pump creates a hollow space or chamber (1) which expands as the pump rotates. As the

chamber expands, the pressure in the chamber decreases. As a result, gas is drawn into the chamber due to the

difference in pressure between the chamber and the inlet (4) to the chamber. (The inlet is the only place where

gas can flow into the chamber.)

Figure 2.1

Typical Rotary Vane Pump,

Schematic Diagram

Once the vane (3) moves past the inlet (4), it seals the inlet against the chamber (1), and the gas becomes trapped

between the vanes (2 and 3). The chamber (1) formed by the enclosed space between the vanes then begins to

decrease in volume as the rotor revolves, compressing the gas. The pressure of the compressed gas becomes

greater than atmospheric pressure. When the vane (2) moves past the exhaust port (5) the compressed gas in the

chamber is forced out through the exhaust port.

This expansion/compression cycle constitutes one complete cycle of pump operation. This cycle is repeated as the

vane (2) passes the intake port and seals it against the atmosphere. Therefore, two pump cycles are performed

during each revolution of the pump rotor.

Содержание 8890

Страница 19: ...19 TROUBLESHOOTING 6 4 Trouble Shooting Guide ...