Operation

52

4.2 Starting Up

The following starting/stopping procedure is a simple example (not binding) and it‟s based on a

simple starting control panel equipped with starting key. Please refer to the genset and/or

genset control panel use & maintenance manual for the starting operation mode.

Before starting the engine, operate the

stop control lever to ensure flexible

motions, and the crankshaft can rotate

smoothly.

Before starting, it is required to

pre-lubricate the oil pump to ensure that

the oil pressure of the main oil channel

reaches 2bar before starting. Failure to

pre-lubricate will easily cause the main

bearing damage and the turbocharger

bearing damage.

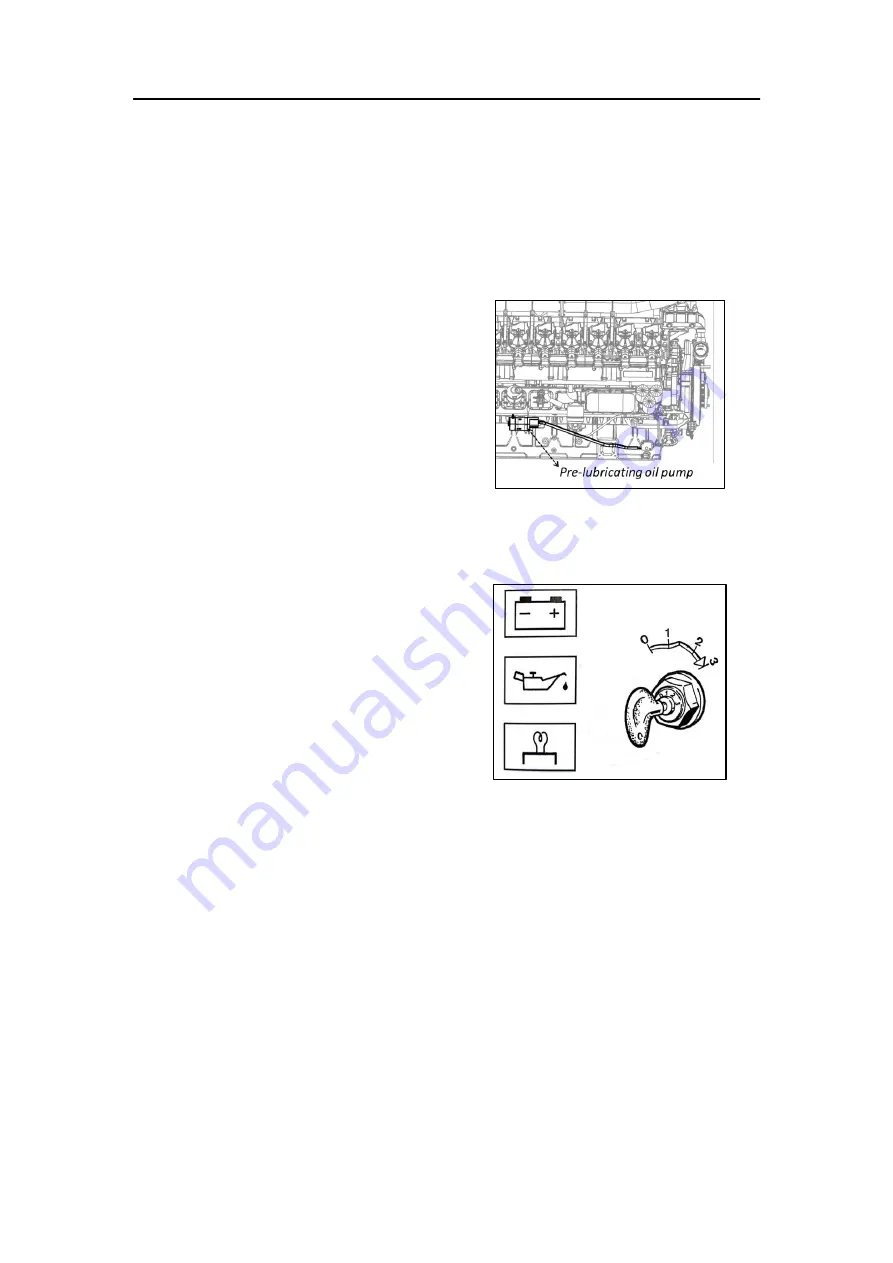

Turn the key to position “1” to power on

the control panel. The “oil pressure

warning lamp" automatically will turn on

for 10s (Safety line test of ultra-low en-

gine oil pressure). It‟s recommended to

test the indicator lamps, bulbs, and but-

tons once (by pressing the touch button

10 on the control panel).

Turn the key to

position “START” to

start the engine and then release the

key. The key will automatically return to

position “1”.

Figure 4.2.A-Pre-lubricating oil pump

Figure 4.2.B-Switch

NOTE

At the start of engine, if the engine fails to start within 10s, immediately release the button

and wait for 1min before retry.

If the engine can‟t be started by three consecutive attempts, stop the attempt and find out

and solve the malfunction before retry.

During the working of

engine, the “oil pressure warning lamp” and the "battery power”

indicator lamps are all off.

All indicator lamps are off during normal running of engine.

In event of abnormality, the “horn” will issue warning sound.

The auxiliary starter shall be used to start the engine under cold temperature.

By activate the electric heating flange via relay, the engine can be started success-

fully under low-temperature environment.

于千钧

“1005098300 - Operation_and_Maintenance_Manual_for_PowerKit_16M33_Series_Gas_Engine, A”

林世龙

许太法

宋安泽

20200425

于千钧

张安勇/Zhang Anyong

王巧荣