WELD THE WORLD

Cod. 006.0001.1960

03/05/2019 V.2.2

Discovery 172T

24

ENGLISH

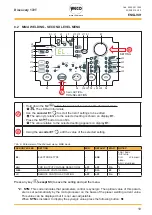

ACRONYM / LED

SETTING

MIN

DEFAULT MAX

USEFUL ADVICE

L18

WELDING CURRENT

MAXIMUM CURRENT WITH RE-

MOTE CONTROLLER

5 A

80 A

170 A

L19

SECOND CURRENT B-LEVEL

10 %

50 %

200 %

* 1

L20

BASE CURRENT

1 %

40 %

200 %

* 1 - * 5

SYn

SYn

SYn

* 6

L21

PEAK TIME

0.1 s

0.1 s

5.0 s

* 5

1 %

50 %

99 %

* 4

SYn

SYn

SYn

* 6

L 21 + L22

PULSED CURRENT FREQUENCY

0.1 Hz 100 Hz

2.5 kHz

* 4

SYn

SYn

SYn

* 6

L 22

BASE TIME

0.1 s

5.0 s

5.0 s

* 5

L 23

DOWN SLOPE

0.0 s

0.0 s

25.0 s

Recommended value 0.5

L 24

FINAL CURRENT

5 A

5 A

170 A

* 2

5 %

5 %

80 %

* 2

L 25

POST GAS TIME

0.0 s

10.0 s

25.0 s

* 3

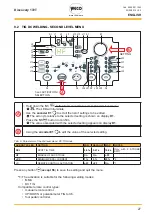

*1:

This parameter is set as a percentage referred to the value of the following parameter:

WELDING

CURRENT

*2:

The value of this parameter can be set as a percentage of the welding current or as an absolute

value expressed in Amperes.

*3: SYN

: This code indicates that parameters control is synergic. The optimal value of this parameter

is set automatically by the microprocessor on the basis of the preset welding current value. This

value can be displayed but it is not user-adjustable.

*4:

Available when parameter

“PUL”= FA.

*5:

Available when parameter

“PUL”= SLo.

*6:

Available in the following mode:

SYNERGIC TIG

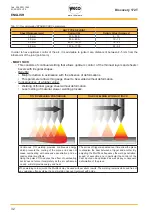

- The SYNERGIC PULSED TIG DC

enables a highly concentrated arc to be achieved. It is a very stable

arc and moves the pool with strong fluctuations. It is ideal for use in spot welding and the creation

of thin fillets. It is recommended for thin layers and in particular where a very stable arc is required

(viscous pools)

In this mode, the welding parameters are pulsed: BASE CURRENT; PEAK TIME; PULSED FRE

-

QUENCY are only displayed and cannot be modified.

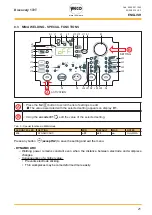

- PRE-GAS TIME

○ Time of gas delivery before the arc strike.

○ This adjustment is required when fixing points must be created or when welding in hard-to-reach

positions that call for the presence of inert atmospheres before striking the arc.

-

Consequences of a higher value:

•

This parameter allows a shielded environment to be created, thereby eliminating contaminants

at the start of the welding pass.

- STARTING CURRENT

○ Unit current output value immediately after the arc strike. The value of this parameter can be

set as a percentage of the welding current or as an absolute value expressed in Amperes. The

parameter is displayed but it is not used during the welding process when the following setting is

Содержание Discovery 172T

Страница 1: ...Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T Instruction manual ENG...

Страница 2: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 2 ENGLISH...

Страница 50: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 50 ENGLISH 13 WIRING DIAGRAM...

Страница 52: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 52 ENGLISH 14 SPARES 14 1 DISCOVERY 172T...

Страница 55: ...WELD THE WORLD Cod 006 0001 1960 03 05 2019 V 2 2 Discovery 172T 55 ENGLISH...