- 12 -

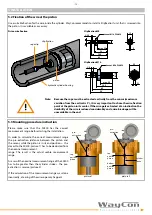

5 INSTALLATION

5�1 General Information Notes

The installation of the transducer to the hydraulic cylinder must be done by trained and qualified fitters only.

5�1�1 Wiring and electrical connections

To avoid damage due to wrong wiring we strongly recommend to do the electrical connection according to the wiring

instructions of the encoder.

All existing safety devices for electrical installations have to be ready for operation and must be checked regularly.

►

Before setting in operation, connect all required strands as per data sheet. To prevent short-circuits, neatly insulate the ends

of all strands which are not required.

►

When pre-assembling the mating connector, comply with any instructions accompanying the connector.

►

Our recommendations regarding cable lengths:

• in case of asymmetrical transmission, i.e. inverted signals are not used, cable length max. 10 m.

• in case of symmetrical transmission (e.g. to RS 422), cable length max. 50 m (cable with twisted pairs of wires).

►

Plug in or pull out mating connector at the encoder only when encoder is de-energized.

►

Make certain that the operating voltage is correct and the max. permissible output current is not exceeded (see data sheet).

►

The operating voltage for encoder and succeeding device must be turned on and off together.

ln order to maintain CE-Conformity the EMC installation conformity must be followed. Shielded cables should be used or control

lines. The cable shield should, if possible be connected fully enclosed (360º) by shielded connectors or cable bushings. This has

to be done at the encoder and transmission end.

►

The protection earth should be put with low impedance on both face and back of the encoder and the transmission end.

►

In case of earth loop problems, the protection earth of the encoder side has to be removed. On this occasion the encoder

should be placed electrically isolated opposite the actuation.

►

The encoder lines should run separately from cables with high noise levels. Consumers with high disturbance levels, e.g.

frequency converters, solenoid valves, contactors etc. should not be connected to the same voltage supply. Otherwise, a

suitable voltage filtering has to be installed.

Note: Please refer to the additional encoder instruction guidelines�

5�1�2 Fixing devices and screws

The bolts, nuts and stud bolts used for fixing the transducer to the cylinder must be at least of quality 8.8. Please refer to the

cylinder manual.

5�1�3 Mounting position and accessibility

Generally the transducer can be installed in any mounting position desired. However the mounting position shall be chosen in such a way that

a good accessibility with respect to later maintenance is ensured. For proper ventilation the testpoint or screwed sealing plug must be the

highest point of the sensor.

5�1�4 Applying extra weight to the transducer

The transducer must always be installed in such a way to the cylinder that no extra load is applied to the transducer. This means that no other

parts or holders are allowed to be fixed to the transducer. If an additional housing is required, it must be fixed directly to the hydraulic cylinder,

not to the transducer.

Note: The transducer must always be installed to the cylinder in such a way that no

extra load is applied to the transducer� This means that no other parts or

holders are allowed to be fixed to the transducer� Do not move or lift the

cylinder by exercising force to the transducer�