PROGRAMMING (NOTE)

SANITIZING THE SYSTEM

12

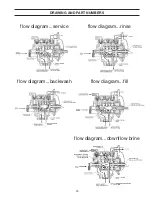

SET TIME OF DAY

The user can also set the time

of day. Time of day should only

need to be set after extended

power outages or when day-

light savings time begins or

ends. If an extended power

outage occurs, the time of day

will flash on and off which indi-

cates the time of day should

be reset.

STEP 1U –

Press SET CLOCK.

STEP 2U –

Current Time (hour): Set the hour of the day

using down or up arrow buttons. AM/PM toggles after 12.

Press NEXT to go to step 3U.

STEP 3U –

Current Time (minutes):Set the minutes of

the day using down or up arrow buttons. Press NEXT to

exit Set Clock. Press REGEN to returnto previous step.

POWER LOSS If the power goes out for less than two

hours, the system will automatically reset itself. If an

extended power outage occurs, the time of day will flash

on and off which indicates the time of day should be reset.

The system will remember the rest.

ERROR MESSAGE If the word “ERROR” and a number

are alternately flashing on the display contact the OEM

for help. This indicates that the valve was not able to

function properly.

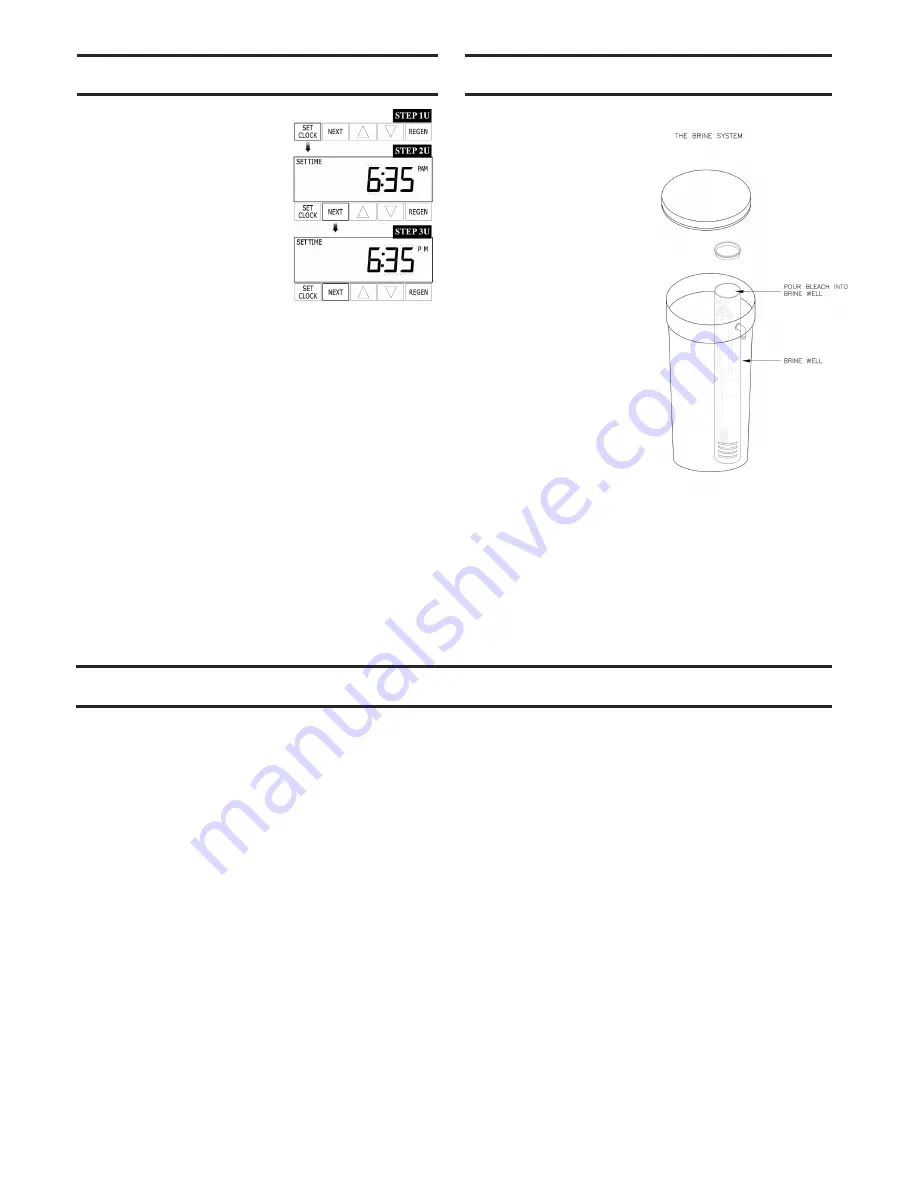

1.

At completion of softener

installation you should

sanitize the system.

2.

Take the lid off of the salt

tank and then take the

cap off of the brine well.

Pour about 3/4 to 1 1/2

ounce of 5.25% common

household bleach into

the brine well. Replace

cap and lid. (This can be

done with or without salt

in tank.)

3.

Press and hold regenera

tion button to start the

regeneration process

immediately.

Each water softener is

handled in a manner to

keep clean and sanitary. The

materials used will not con-

taminate your water supply

or cause bacteria to grow.

However, during shipping,

storage, installation, and

operation, bacteria growth

could develop

.

Some water

supplies may require period

ic

disinfecting.

Components:

The control valve consists of the following components

1.

Drive Assembly

2.

Drive Cap Assembly, Main Piston and

Regenerant Piston

3.

Spacer Stack Assembly

4.

Injector Cap, Screen, Injector Plug and Injector

5.

Refill Flow Control Assembly or Refill Port Plug

6.

Drain Line Flow Control and Fitting Assembly

7.

Water Meter or Meter Plug

8.

Installation Fitting Assemblies

9.

Bypass Valve (optional)

DRIVE ASSEMBLY

The drive assembly consists of the following parts:

•

Drive Bracket

•

Printed Circuit (PC) Board

•

Motor

•

Drive Gears

•

Drive Gear Cover

The drive bracket holds the PC board, the motor, the drive

gears and the drive gear cover in place.

The PC board receives and retains information, displays the

information,determines when to regenerate and initiates

regeneration. The display shows different types of information

in the initial system set up (for softeners or filters), installer

displays/settings, diagnostics, and valve history or user dis-

plays/settings.

The PC board’s two-prong jack connects wires to the direct

current (DC) motor. The motor is held in place on the drive

bracket by a spring-loaded clip and a

small bulge in the plas-

tic, which fits in one of the slots on the motor housing. The

motor turns drive gears that drive the piston to cycle positions

for backwashing, regeneration, rinsing, refill or service. The

motor is fully reversible (turns both ways) and changes direc-

tion of rotation to change the direction of piston motion. The

motor is easily replaced if necessary.

There are three drive gears held in place by the drive gear

cover. All three drive gears are the same size. A reflective

coating is applied to the gears. As the center drive gear turns

a light shines on the coating and a light sensing diode deter-

mines if a light pulse was returned. The PC board counts the

pulses and determines when to stop driving the motor.

SYSTEM COMPONENTS DESCRIBED

Figure 16:

The Brine System