Revision 1.8 / June 2016

52

Oil change

In the case of the pumps of the series

MR120, MR125, MR130, MR135, MR150

the oil viewing glass (Pos.

27) in the bearing housing (Pos. 11) must be checked every day for damage and that there is enough oil in the power frame

component, in particular every time before the pumps are used. The oil viewing glass in the bearing housing must always be

filled up to the middle. Please use the following oil type that is applicable for your application! If the pump is to be used in an

area that is combustible where ATEX applies, the oil viewing glass is replaced by a screwed plug.

Standard first filling of Watson-Marlow MasoSine

Pumps

• For –10°C to 60°C

Klüberoil 4 UH 1-220 N (lube oil for the food and pharmaceutical industry)

Oil grades for ex-zones

Only the following oil type may be used in pumps operated in explosive areas:

Klüberoil 4 UH 1-220 N (lubrication oil for the food and pharmaceuticals industries)

Filling volumes

MR120 approx. 0,2 litre MR125 approx. 0,25 litre MR130 approx. 0,25 litre

MR135 approx. 0,3 litre MR150 approx. 0,5 litre MR160 approx. 0,5 litre

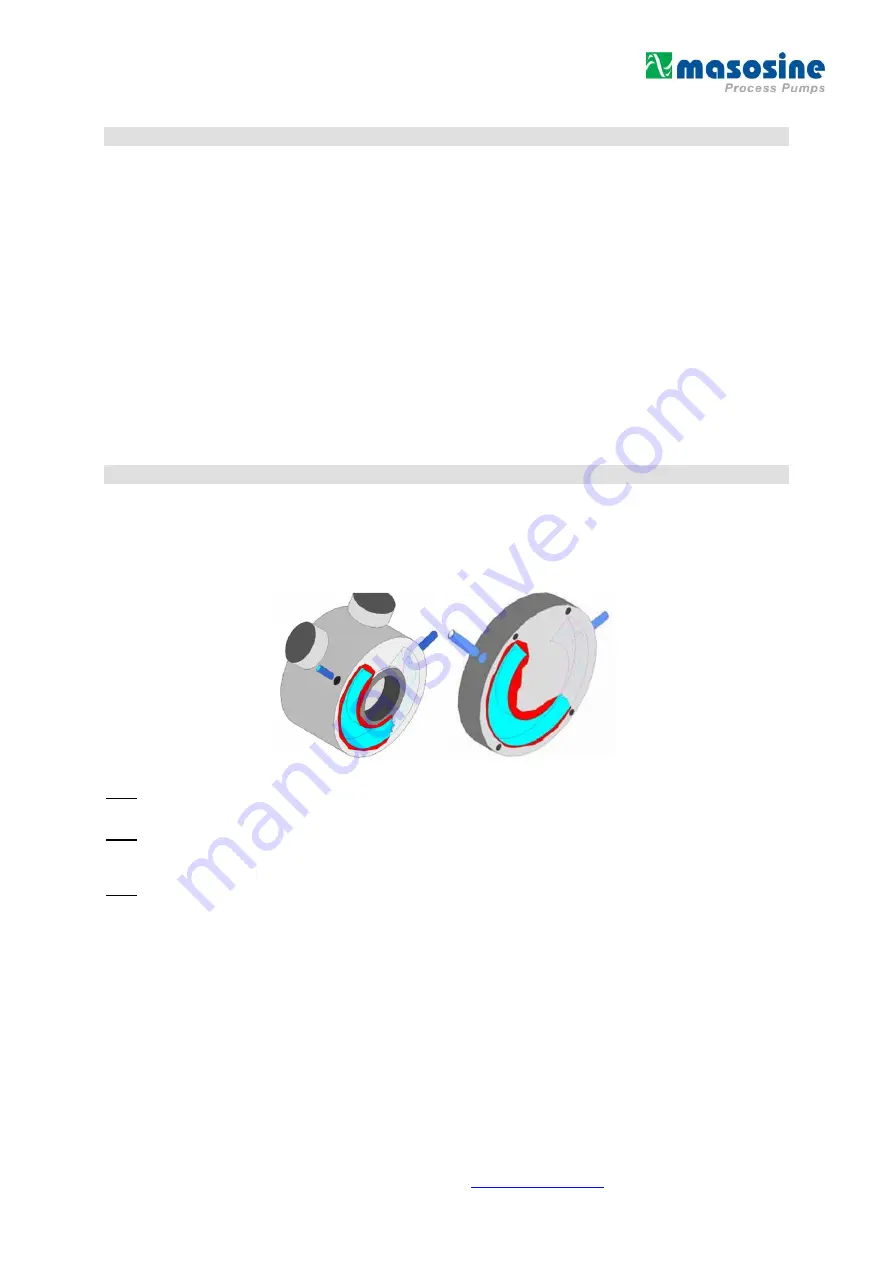

Heating and Cooling Option

Special versions of MasoSine

MR120, MR125, MR130, MR135, MR150

pumps can be heated or cooled to

provide the cor-rect temperature for your process - pumping chocolate or ice cream, for example

—by passing fluid at the tem-

perature required through crescent-shaped channels in the pump housing and the front housing. The pump has 1/4in or 1/8in

connections on two sides through which the heating or cooling agent flows. The position of the connections varies depending on

the model. Counter pressure should not exceed 1 bar.

Note:

Most pumps can be retro-fitted to allow heating and cooling.

Note:

The connections on the front cover may hinder some maintenance work at the pump. In most cases, the heating / cooling

of the pump housing is sufficient. Maintenance is not hindered by the connections..

Note:

If a heater is used to maintain a raised temperature, that temperature must be approved by MasoSine.