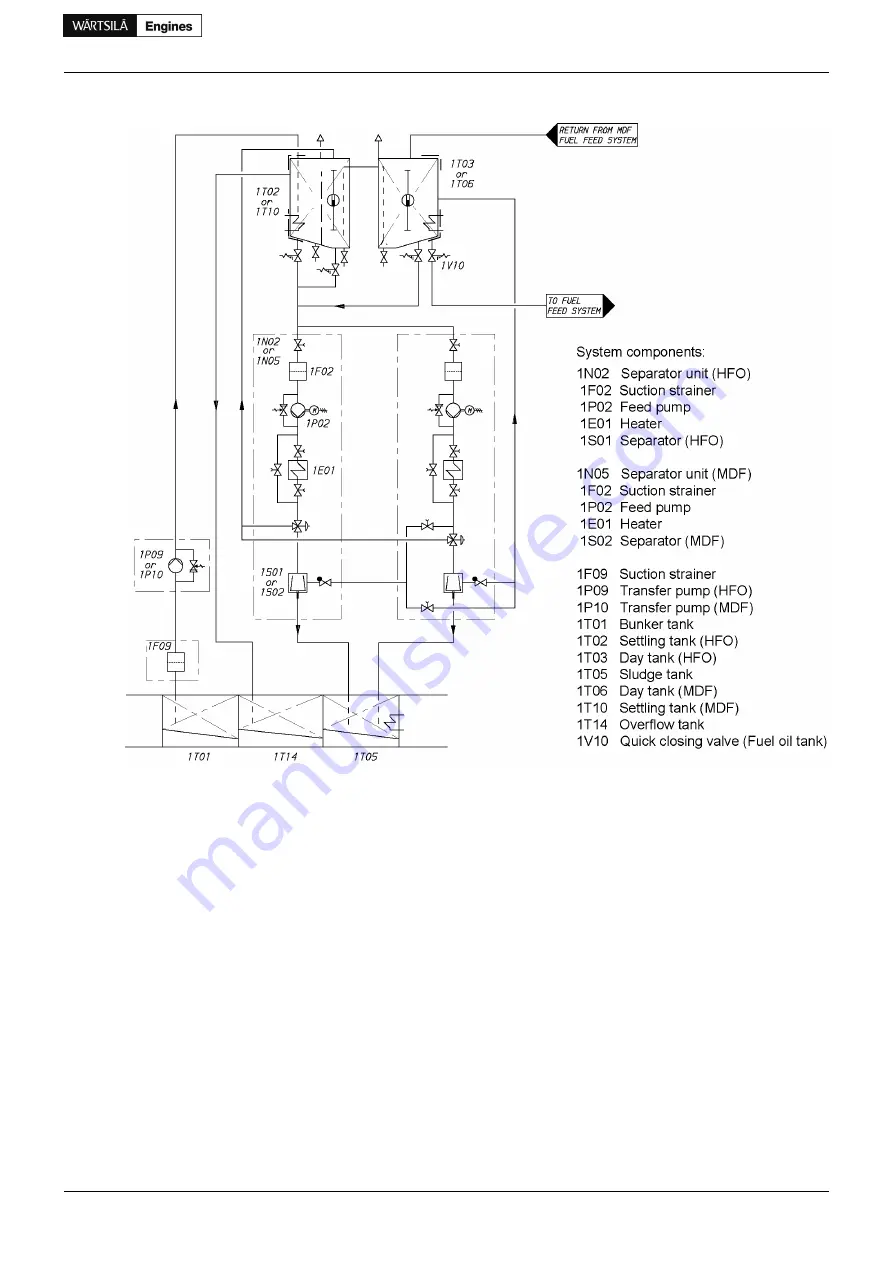

Figure 6.9

Fuel transfer and separating system (3V76F6626d)

Separator feed pumps (1P02)

Feed pumps should be dimensioned for the actual fuel quality and recommended throughput of the separ-

ator. The pump should be protected by a suction strainer (mesh size about 0.5 mm)

An approved system for control of the fuel feed rate to the separator is required.

MDF

HFO

Design data:

0.5 MPa (5 bar)

0.5 MPa (5 bar)

Design pressure

50°C

100°C

Design temperature

100 cSt

1000 cSt

Viscosity for dimensioning electric motor

Separator pre-heater (1E01)

The pre-heater is dimensioned according to the feed pump capacity and a given settling tank temperature.

The surface temperature in the heater must not be too high in order to avoid cracking of the fuel. The tem-

perature control must be able to maintain the fuel temperature within ± 2°C.

Recommended fuel temperature after the heater depends on the viscosity, but it is typically 98°C for HFO

and 20...40°C for MDF. The optimum operating temperature is defined by the sperarator manufacturer.

The required minimum capacity of the heater is:

Product Guide Wärtsilä 34DF - 3/2012

55

Product Guide

6. Fuel System