WINCH MANUAL

MAINTENANCE pRECAUTIONS

9

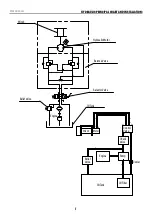

6. The opening pressure of the balancing valve must be 0.1-0.4Mpa

higher than the brake, or the winch will shake when lowering it down.

Our company has tested hoisting and adjusted balancing valves for

every winch before it leaves the factory. Therefore, there is no need

for users/operator to adjust it at all, But if there are special cases

where the users need to adjust it, the users can spiral the adjusting

screw outward, thus making the opening pressure higher, Never

try to adjust the balance valve yourself use a specialist person or

service agent.

7. If there is an abnormal pressure increase in the system, the users

must stop using the winch immediately. Check if there is leakage of

the oil, and if the hydraulic motor is normal. Usually, when hydraulic

motor works under the load, the leaked oil from the pipe must not

surpass 1m/m. Plenty of leakage demonstrates a damaged hydraulic

motor, which must be repaired or replaced immediately. Or, if the

hydraulic motor is in good condition, check other parts inside the

system.

8. Check the operation of the hydraulic winch and its systems regularly

during the work or weekly. In case of abnormal temperature rise,

leakage, abnormal noise and vibration or pressure fluctuation, the

user should stop the winch immediately to check the causes and

overhaul it.

9. Pay attention to the tank’s oil and its level. If there is much foam, the

users should stop immediately to check whether air leaks from the

oil inlet of hydraulic system, the return oil port below the water, and

whether hydraulic oil is emulsified by the entrance of the water.

10. If the winch is showing signs of degraded performance change the

hydraulic oil. Do Not mix old and new oil always replace all.

11. Put 90 # gear oil into the winch speed reducer before using it and

replace the oil after 100 accumulated working hours. First remove

the screw plugs on the drum, then slowly roll the drum to make

drum block hole aim at the block hole on the planetary gear reducer.

Carefully take the plug out with an Allen Key. Drain all the used oil

and add the new oil. Tighten each and every plug.

12. Regularly check the oil filter, which should be cleaned and replaced

regularly.

13. Standing under the winch hook is strictly prohibited.

Overhaul

When the hydraulic winch doesnt work or has malfunctioned is confirmed,

the operator/user can check and repair if qualified to do so. in instances

where user is not able to do this, then do not dismantle or repair. Contact

a professional repair specialist to overhaul. Be careful when dismantling

this hydraulic winch that you dont make scratches or indentations on

precision parts, especially to surfaces of moving and seal parts. Repair or

replace damaged parts immediately. Before assembling, all parts must be

cleaned, and coated with lithium grease (If applicable)

Lifting

These winches are not recommended to be used for lifting, if you use your

winch for hoisting (lifting) then you need to implement a safety factor 5:1.

Ensure when using for lifting there is a minimum of 1 layer on the drum at

any time and pay attention to fixations and drum capacity.

Storage

The Hydraulic winch should be stored in the warehouse where the air is

dry and no corrosive gas. Do not put it under high temperature 50°C or at

a -20°C environment for long-term storage, in case the aging of sealing

parts are accelerated.

If the Hydraulic winch is in a long-term storage, the user should drain all

the oil from it, and fill the machine fully with Turbine Oil with a low acid

value.

LUBRICATION:

–

All moving parts within the Winch having been Lubricated using high

temperature lithium grease at the factory. No internal lubrication is

required.

–

Lubricate Cable Assembly periodically using a light penetrating oil.

CABLE ASSEMBLY REpLACEMENT

If the wire rope has become worn or is beginning to show signs of strands

breaking, it must be replaced before being used again.

1. Turning clutch to the “CLUTCH OUT” position.

2. Extend cable assembly to its full length. Note how the existing cable

is connected to the drum.

3. Remove old cable assembly and attach new one as the ld cable

connected to the drum. Insert the end of the new rope and secure

the screw being tightly screwed

4. Turning clutch to the “CLUTCH IN” position.

5. Retract cable assembly onto drum, first five wraps being careful

not to allow kinking, then winch cable must be wound onto the drum

under a load of at least 10% rated line pull.

WARNING

Only replace the wire rope with the identical replacement part

recommended by the manufacturer. Ropes are not part of any

warranty offered and the sole responsibility of the operate / user to

maintain or change.

Содержание 13JR02H-CAD

Страница 12: ...Winch Manual SPECIFICATIONS 12 WINCH ASSEMBLY DRAWING 13JR02H CAD...

Страница 15: ...Winch Manual SPECIFICATIONS 15 WINCH ASSEMBLY DRAWING 15JR02H CAD...

Страница 18: ...Winch Manual SPECIFICATIONS 18 WINCH ASSEMBLY DRAWING 20JR02H CAD...

Страница 21: ...Winch Manual SPECIFICATIONS 21 WINCH ASSEMBLY DRAWING 25JR02H CAD...

Страница 24: ...Winch Manual SPECIFICATIONS 24 WINCH ASSEMBLY DRAWING 30JR02H CAD...