WINCH MANUAL

IMpORTANT SAFETY INSTRUCTIONS

3

IMpORTANT SAFETY INSTRUCTIONS

DANGER

DO NOT EXCEED RATED CAPACITY.

INTERMITTENT USE ONLY - COOL BETWEEN USES.

DO NOT

use winch for lifting/moving people or live animals.

A minimum of five wraps of cable around the drum barrel is necessary

for pulling and holding the rated load. The cable clamp is not designed

to hold the load without the 5 wraps of cable around the drum.

(usually marked red on the drum end of the cable)

DANGER

Keep yourself and others a SAFE DISTANCE to the side of the cable

when under tension.

NEVER

stand or step over a cable, or near a cable under load using a

winch blanket or sail is strongly recommended.

DON’T

move the vehicle to pull a load (towing) on the winch cable.

This could result in cable breakage.

DANGER

DO NOT

exceed maximum pull rating. Avoid “shock loading” by using

the remote lead switch intermittently to take up the slack in the wire

rope. “Shock loading” can far exceed the rated capacity for the wire

rope and drum and will result in damaging winch and brake. By doing

so will void any warranty.

DANGER

DO NOT

use you winch as securing device it is not designed for this

and will result in damaging winch and brake and will void any warranty.

DO NOT

exceed maximum line pull ratings shown on the tables.

DO NOT

use as a hoist. Do not use for overhead lifting.

DANGER

NEVER

cut, weld, or modify any part of the winch or cable. By doing

so will void any warranty

DANGER

When re-spooling the cable

Ensure that the cable spools in the

under-wind position with the cable entering the drum from the

bottom, not the top. To re-spool correctly, and while wearing gloves,

keep a slight tension on the cable while pushing the remote control

button to draw in the cable. Walk toward the winch

NEVER

allowing

the winch cable to slide through your fingers or hands.

DO NOT

let your hands get within 12”(30cm) of the winch while re-

spooling. Turn off the winch and repeat the procedure until a few feet

of cable is left. Disconnect the remote control and finish spooling by

hand by rotating the drum manually with the clutch disengaged. Keep

hands clear of the fairlead and drum while the winch is under power.

DANGER

Failure to read and understand these warnings may result in personal

injury and/or property damage.

Always use gloves to protect hands when handling any type or cable/

rope. Never let the cable slide through your hands.

NEVER

connect the cable back to itself.

Always apply blocks/chocks/straps to the wheels of the vehicle/

equipment when on an incline and in transportation.

No modifications, alterations, or deviation to the winch are authorized

by the manufacturer and MUST NOT be made. By doing so will void

any warranty.

Duration of winching pulls should be kept as short as possible. If

the motor becomes uncomfortably hot to the touch, stop winching

immediately and let it cool down for approx 8 mins minutes. Do not

winch for more than two minutes at or near the maximum rated load

without resting for 8 minutes.

DANGER

If the motor stalls

DO NOT

maintain winching. Winches are designed

and made for intermittent use and should be used in conjunction with

their duty cycles.

NEVER

release the free-spool clutch when there is a load on the

winch as the load will roll backwards.

Use hand saver hook when handling the hook for spooling or un-

spooling the wire rope.

NOTICE

The winch and its all-derivative types are rated at rated capacity when

spooling the first rope layer on the drum. Overloading can damage

the winch / motor / or wire rope.

For loads over 70% of rated line pull, we recommend the use of the

pulley block / snatch block to double the wire rope line and reduce the

strain. This will aid in two ways:

It will reduce the number of rope layers on the drum and reduce the

load on the wire rope by as much as 50%. When doubling the lineback

to the vehicle, always attach to the frame or another load bearing

point..

Содержание 13JR02H-CAD

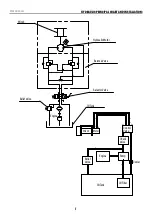

Страница 12: ...Winch Manual SPECIFICATIONS 12 WINCH ASSEMBLY DRAWING 13JR02H CAD...

Страница 15: ...Winch Manual SPECIFICATIONS 15 WINCH ASSEMBLY DRAWING 15JR02H CAD...

Страница 18: ...Winch Manual SPECIFICATIONS 18 WINCH ASSEMBLY DRAWING 20JR02H CAD...

Страница 21: ...Winch Manual SPECIFICATIONS 21 WINCH ASSEMBLY DRAWING 25JR02H CAD...

Страница 24: ...Winch Manual SPECIFICATIONS 24 WINCH ASSEMBLY DRAWING 30JR02H CAD...