27-05-19 UNI-SAN Domestic Instructions Page 11

DO NOT DISCHARGE LIQUID INTO THE PUMP IF IT IS NOT OPERATING.

NOTE In the warranty period, any work not described in this manual must be carried out by Wallace Pumps Service

Agents otherwise your warranty and the product's durability period will be invalidated.

ALWAYS ensure isolation and disconnection of the power supply

to the pump before and whilst carrying out

any servicing work on the unit. Also ensure no liquid will flow into it during servicing.

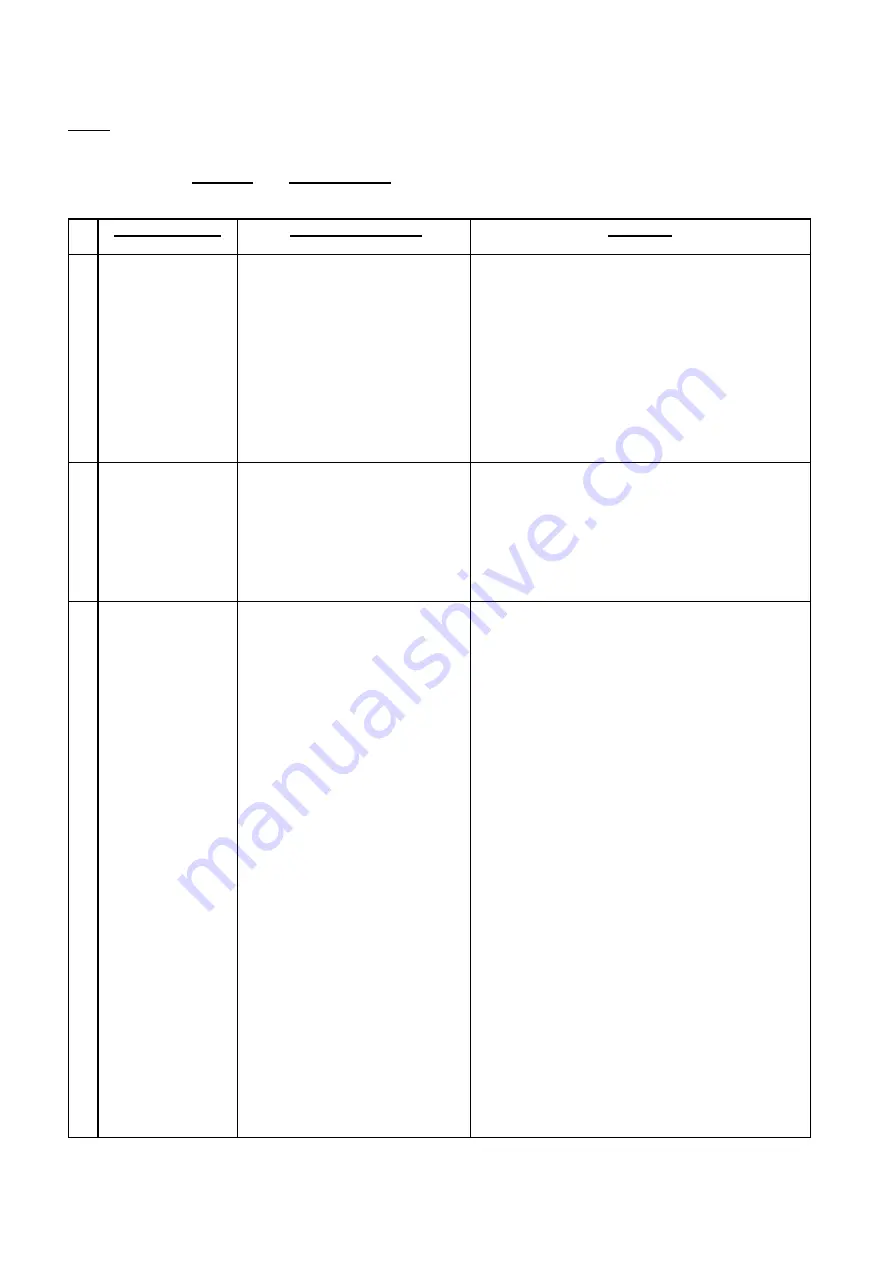

OCCURRENCE

POSSIBLE CAUSE

REMEDY

1. -Motor

runs

continuously

without clearing

the liquid.

- Switch operated by water level

remains in the ON position

because :

a. pipework is blocked; or

b. pump is blocked; or

c. tank is blocked; or

d. check valve installed back to

front

e. delivery hose is kinked.

-Check that the pipework is clear.

-Turn off the power and check that the pump can

rotate freely in both directions by turning the

shaft at the top end of the motor with a

screwdriver.

-If blocked, clear the obstruction.

- Reverse the valve.

-PVC Pipes are recommended.

2.

-Pump runs but

delivers little or no

liquid.

-Delivery head (combination of

vertical and horizontal pipe

lengths, pipe bends and size) is

too high for the unit.

-Check the system against the pump operating

parameters. Refer Section 5 (Building design). If

the building or application design is in excess of

the pump capability shown on the chart, call our

office for advice.

-Check that the pump is not pumping the water

level down too low. ( Refer fault 9 below ).

3.

- Pump starts but

takes over 10

seconds to reduce

the liquid level in

the tank

( as seen through

the inspection lid).

-Delivery line is partially blocked

or too small.

-Wrong type of delivery valve

used ; eg spring poppet type

-Float level switch is too long.

-Float level switch is hung up.

-Float or pressure switch is

faulty.

-Pump is not venting.

-Tank is not venting

-Unblock and/or change the pipework to the

minimum ID. Refer Section 5( Hydraulic

capability ).

-Always use a 25 swing check valve in a vertical

position within 1 metre of pump.

-Check that the pump is not pumping the water

level down too low. (Refer fault 9 below).

-Remove the obstruction via the inspection lid.

-Replace the switch.

-Visually check that the tank vent pipe is clear ;

or by releasing the pipe from the tank and blow

down it; or by removing it and flush clean.

-Check that the vent functions:

. Liquid should rise in the vent tube until the

pump starts;

.When the pump runs, little or no liquid should

flow through the vent tube. Remove the

inspection lid to check the return flow into the

tank;

.When the pump stops, the liquid in the vent

tube should draw down to empty.

-Check that the pump is not pumping the water

level down too low. (Refer fault 9 below).