26

Periodic inspection

To ensure efficient and smooth operation of the pump, periodically inspect the pump and

installation. When inspecting, overhauling, or if repair is necessary, stop the pump operation and

contact the supplier as necessary.

The overhauling and repair work for Walchem pumps must be performed by qualified personnel

who have been trained and certified by the pump supplier. User’s failure to observe this instruction

exempts Walchem from the responsibility for personal injury or damage to the equipment or facility

that result from its misuse.

1. Valve Unit

Check the valve balls, valve seats and valve guides every 6 months. If flaws or worn parts are

found, replace them.

2. Diaphragm

Check the diaphragm every 6 months if the usage is fairly light. The life of the diaphragm

depends on the characteristics, pressure, temperature, etc. of the liquid being pumped. If any

deformation or crack is found, the diaphragm should be replaced with a new one.

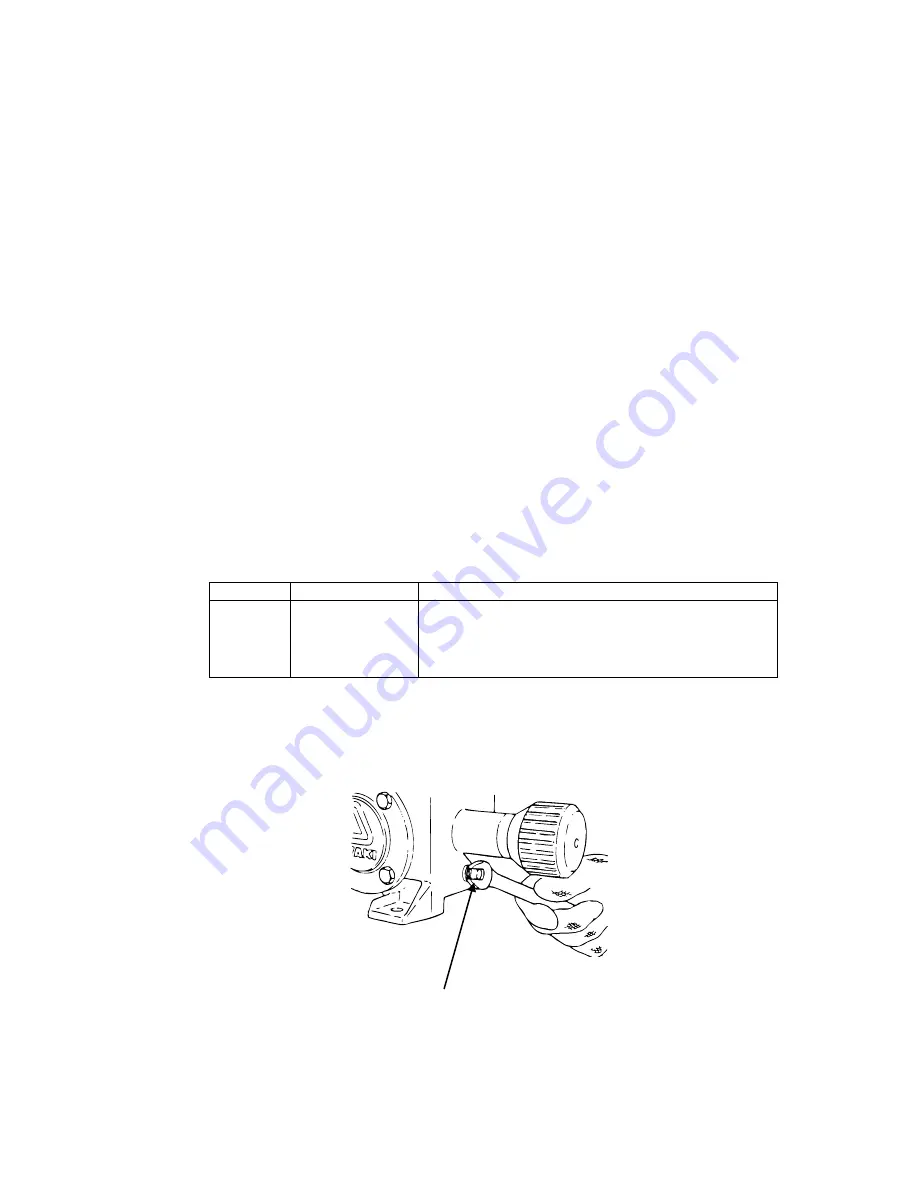

3. Oil

Change the oil in the drive unit once a year. If emulsification of the oil is found during

inspection, immediately change the oil. Remove the drain plug and drain the drive unit. Flush

the inside with oil to clean it. Then, add new oil up to the specified level of the oil gauge.

Ensure any replacement oil is SAE (80W-90) and must exceed API Service GL-4.

Model

Oil Qty

Recommended Oil

LKN

7.44oz

(220 mL)

Esso (Exxon) GP80W-90, Shell Spirax/EP80,

Mobil Pegasus Gear Oil 80

(Automobile Gear Oil SAE-80, API Grade GL-4),

Castrol Hypoy Gear Oil

Contact your Walchem distributor if the oil listed above is unavailable. Use of incorrect oil may

shorten the life-term of the gear unit.

Drain plug