5

introduction

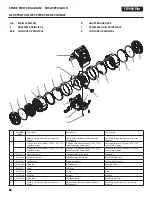

fc9900 Plus

2

introduction

This High Volume/Low Pressure (HVLP) spray system is designed

for applying coatings to surfaces that can be sprayed faster

than brushing or rolling and are too small for traditional airless

sprayers. Components of this system include a power switch, a

power cord, a filter warning light, a circuit breaker switch, a dual

filtration system, a cup holder, an air hose, and an air outlet.

The turbine is also equipped with a tool box. It is located on the

reverse side of the turbine and can be used to store projector

sets or any other small spare parts.

4

6

7

8

5

2

3

1

1.

Circuit breaker switch

2.

Filter warning light

3.

Filter

4.

Air inlet

5.

Cup holder

6.

Filter (in the end of can)

7.

Power switch

8.

Air outlet

* Air hose not pictured.

With this HVLP spray system, you can achieve the highest

quality professional finish possible with little or no preparation

or setup time. Please review all the information contained in

this manual before operating the system.

2.1

technical data

Voltage

100-110V~, 50/60 Hz or

220V-240V~, 50/60 Hz

Power consumption P1

1836 W

Max. current comsumption

100-110V~

220V-240V~

13,4A

9,0A

Max. air ram pressure

0,72 bar (10,5 psi)

Rpm

21 000 rpm

Turbine weight

15 kg

Mains cable

3 m

Container capacity

1 liter

Air hose

9,1 m

Whip hose length

1,5 m

Nozzle set (standard)

No. 4 (1.8 mm)

Max. permissible coating

temperature

43ºC

Typical coating flow rate

0,35 l/min

Max. noise level

turbo-blower

75 dB (A) *

paint spray gun

76 dB (A)

* Measuring location: 1 m in distance from the unit 1.60 m

above the floor, reverberant floor.

** Measuring location: 2.5 m distance from the unit 1.60 m

above the floor.