27

WAGNER Project Pro 117 - 0418B

Components and Description

The shipping carton for your painting system contains the following:

• Suction tube and return tube (including inlet filter and 3 clips)

• Spray tip assembly

• Basic unit

• 7.5 m, 6.35mm internal diameter pressure hose

• Spray gun with two filters (L-XXL; one in gun, one separate)

• Oil flask

• Instruction manual

Figure 1 - Controls and Functions

(further, detailed descriptions of the individual items can be found in the relevant section of the operating instructions)

Item

Component

Description

A)

ON / OFF Switch ............................The ON/OFF switch turns the power to the sprayer on and off (O=OFF, l=ON).

B)

PRIME / SPRAY Knob

....................

The PRIME/SPRAY knob directs fluid to the spray hose when set to SPRAY or the return tube when set

to PRIME. The arrows on the PRIME/SPRAY knob shows the rotation directions for PRIME and SPRAY.

The PRIME/SPRAY knob is also used to relieve pressure built up in the spray hose (see Pressure Relief

Procedure).

C)

Quickflo™ Valve

.............................

The Quickflo™ valve is designed to keep the inlet valve open and from sticking to dried materials.

The Quickflo™ valve is activated manually by the user.

D)

PressureTrac™

................................

The PressureTrac™ regulates the amount of force the pump uses to push the fluid.

E)

Pump Section .................................

A piston in the pump section moves up and down to create the suction that draws fluid through the

suction tube.

F)

Suction Tube ..................................Fluid is drawn through the suction tube into the pump.

G)

Return Tube

....................................

Fluid is sent back out through the return tube to the original container when PRIME/SPRAY knob is in

PRIME position.

H)

Inlet filter ..........................................The inlet filter strains the spray material to prevent the system from becoming clogged.

I)

Spray Gun ........................................For application of the coating material and regulation of the pump capacity.

J)

Spray Hose ......................................The spray hose connects the gun to the pump.

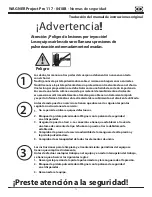

When working outdoors:

Danger

Vapors containing solvents may not be allowed to

blow toward the unit.

Note the direction of the wind.

Set the unit up in such a way that vapors containing

solvents do not reach the unit and build up there.

A minimum distance of 5 m between the unit and

spray gun is to be maintained.

U

Cleaning the unit

Danger

Danger of short circuit through penetrating water!

Never spray down the unit with high-pressure or

high-pressure steam cleaners.

U

Cleaning units with solvents

Danger

When cleaning the unit with solvents, the solvent

should never be sprayed or pumped back into a

container with a small opening (bunghole). An

explosive gas/air mixture can be produced. The

container must be earthed.

Do not clean the device or accessories with

flammable solvents with a flash point below 21 °C.

U

Earthing of the object

The object to be coated must be earthed.

Technical Data

Pump type

Piston pump

Power source

220 V

~

60 Hz

Power consumption

670 W

Fusing

Only connect to sockets protected

with an FI fuse (16 A)

Double insulation

Max. spray pressure

200 bar

Max. delivery rate

1,0 l/min

Sound pressure level

71,4 dB (A)

Oscillation level

< 2,5 m/s²

Max. temperature of coating

substance

40°C

Max. nozzle size

XL (0,019")

Hose length

7,5 m

Weight

7,8 kg

Coating Materials Suitable for Use

Water-based and solvent-containing lacquers and glazes.

Paints, oils, release agents, synthetic enamels, PVC lacquers,

undercoats, base coats, fillers and anti-rust paints.

Dispersion and latex paints for interior use.

Coating Materials Not Suitable for Use

Materials that contain highly abrasive components, facade paint,

caustic solutions and acidic coating substances.

Materials with a flash point below 21°C.

i

In order to ensure compatibility of the coating substance

with the materials used to manufacture the device, please

contact Wagner Service in cases of doubt.

Содержание 0418B

Страница 39: ...35 WAGNER Project Pro 117 0418B...