TEMPERATURE PROBE TEST

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

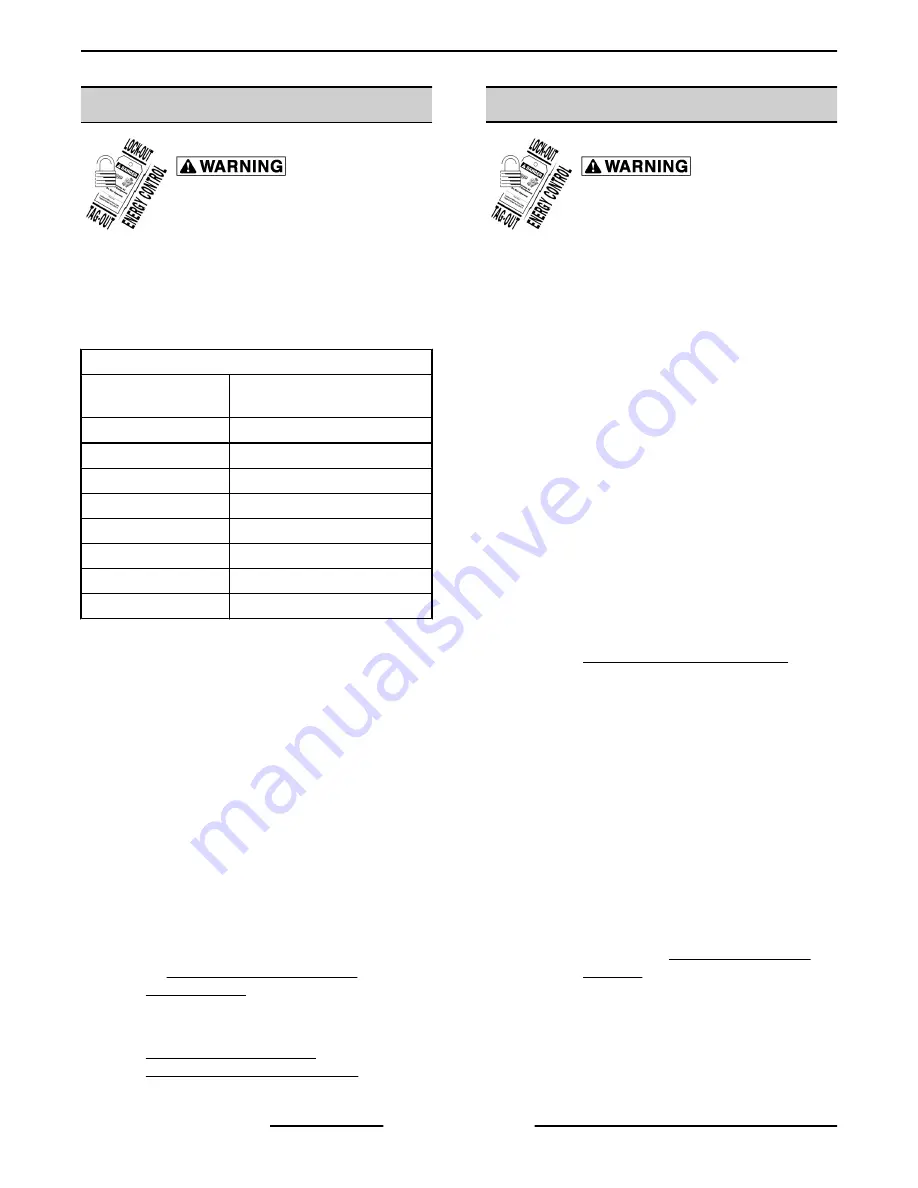

Temperature to Resistance Chart

Degrees

(Fahrenheit)

Resistance

77°

90k - 100k

200°

8354

250°

3794

300°

1903

250°

1032

400°

609

450°

374

500°

241

1.

Place a shielded thermocouple in center of oven

cavity.

2.

Turn oven on and set to 350° Fahrenheit.

3.

Remove temperature control knob.

4.

Hold down "-" (minus) button for 3 seconds to

enter diagnostic mode.

NOTE:

Display should now show oven temperature

reported by probe.

5.

Allow temperature to stabilize (typically 3 cycles).

•

If thermocouple temperature is within 5°

Fahrenheit of display temperature, probe is

functioning properly.

•

If temperature difference between

thermocouple and display is greater than 5

degrees but less than 20° Fahrenheit, refer

to: TEMPERATURE CONTROL

CALIBRATION to calibrate.

•

If temperature difference is greater than 20°

Fahrenheit turn off oven, replace

TEMPERATURE PROBE, then repeat

TEMPERATURE PROBE TEST.

HEATING ELEMENT TEST

Certain procedures in

this section require electrical test or

measurements while power is applied

to the machine. Exercise extreme

caution at all times and follow Arc Flash

procedures. If test points are not easily

accessible, disconnect power and

follow Lockout/Tagout procedures,

attach test equipment and reapply

power to test.

1.

Turn the power switch ON and set the oven

temperature control to the highest setting.

2.

Measure the voltage at the heating element

terminals and verify it against the data plate

voltage.

A.

If voltage is incorrect, find the source of the

problem.

B.

If voltage is correct, check current draw

(amps) through the heating element lead

wires.

NOTE:

This method is preferred over a resistance

check when a clamp on type amp meter is available.

1)

If current draw is correct then heating

element is functioning properly. See

HEATING ELEMENT VALUES table.

2)

If current draw is not correct, turn the

power switch OFF and disconnect the

electrical supply to the oven.

a.

Replace heating element, then

proceed to step 3.

C.

If unable to check current draw, a resistance

check may indicate a malfunctioning

element.

1)

Turn the power switch OFF and

disconnect the electrical supply to the

oven.

2)

Remove the lead wires from the

heating element and check resistance

(ohms). See HEATING ELEMENT

VALUES table.

3.

Check for proper operation.

VC5ED FULL SIZE ELECTRIC CONVECTION OVEN - SERVICE PROCEDURES AND ADJUSTMENTS

F45652 (0217)

Page 16 of 31