Owner’s Manual #513642 Rev.4

10

CC Model Machines

4

Connect the refrigeration lines from the line sets

to the machine. Access the machine from the left

or right service panel. The refrigeration system

has a charge of dry nitrogen. Use caution when

connecting the lines. Connect the suction line fi rst

then connect the liquid line. Run the refrigeration

lines under the machine. There is approximately 6”

of clearance between machine and the fl oor. The

stainless steel legs are adjustable and can raise

the machine up to 7” off the fl oor if necessary.

Wrap the suction solenoid in a cold wet rag when

soldering to prevent damage to the solenoid. Also,

be aware of the electrical conduit inside custard

machine while soldering the refrigeration lines. A

liquid line dryer is supplied with the machine and

should be the last connection made in the system.

Use good piping techniques to keep the system

clean. Do not leave the lines open and exposed

for a long period.

5

After fi nishing the refrigeration connections,

connect power to the machine. Refer to “B. Running

Electrical Lines” for the proper procedures. Check

the rotation of the auger shaft. When looking at

the machine from the front, the shaft needs to

turn counterclockwise. If the shaft is turning the

wrong direction, shut off power to the cylinder and

switch the L1 and L3 wires. Check rotation again to

verify the shaft is rotating counterclockwise. Once

verifi ed, tighten the screws on the electrical box

cover.

If the machine is single phase and the auger shaft

rotation is clockwise, then complete one of the

following procedures. Check rotation after each

procedure.

A. Change the T1 and T3 output leads going to

the motor from the drive.

B. Change the leads inside the motor electrical

box.

6

Condensing units ship from the factory with 20

lbs of R-404A for up to a 50’ line set. Add 1 lb of

refrigerant for every 10’ increase to the line set.

Line set max 100’. Use good refrigeration practices

to add additional charge to the system if needed.

Make sure the suction solenoid is energized and

that the shut off valves are open.

F. RUNNING PRODUCT AND SETTING PRESSURES

FOR THE CUSTARD MACHINE

NOTE

Complete the Custard Machine Start-Up and Train-

ing Checklist located with the spare parts kit or in

the back of this manual and send it to Stoelting.

1

Remove all spare parts from the hopper before

running product. Unwrap the parts and check for

damage. Refer to the list in the back of this manual

to make sure no parts are missing. The cylinders

need to be under a load to set the pressures.

2

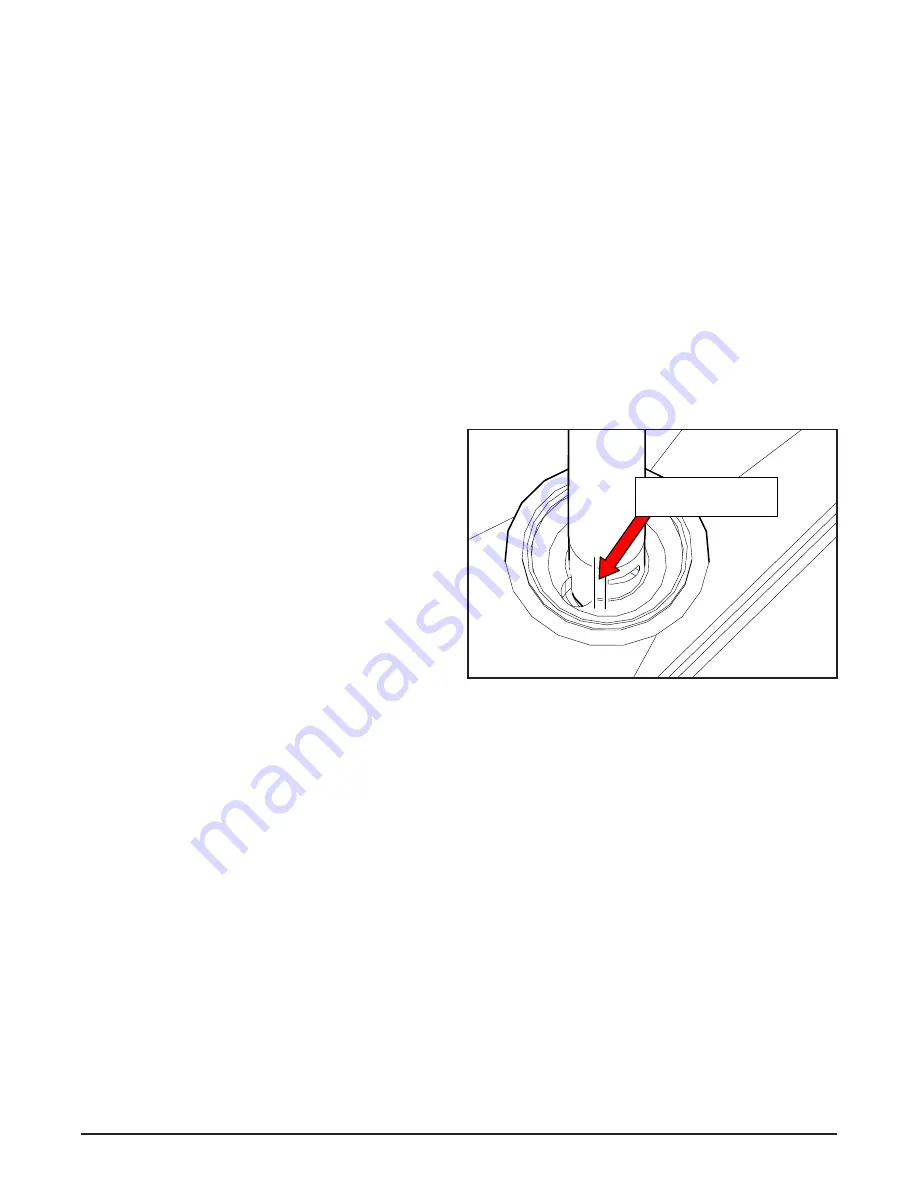

Install the fl ow valve and rotate it so the cutout

is about 3/32” from the cutout in the hopper (see

below). Fully close the fl ow control knob. Install

the fl ow rod. If the fl ow rod cannot be installed

without moving the fl ow valve, loosen the locknut

on the rod and adjust it. Make sure both rod ends

lay fl at, then tighten the locknut.

3

Disassemble, clean and sanitize each freezing

cylinder. Refer to the Section 3 for proper

instructions.

Approximate width

of nickel (ideally 3/32")

Approximate width

of nickel (ideally 3/32")

Содержание Stoelting CC Series

Страница 1: ...CC Model Machines OPERATORS MANUAL Manual No 513642 Rev 4 A VOLLRATH DIVISION...

Страница 2: ......

Страница 6: ......

Страница 12: ...Owner s Manual 513642 Rev 4 6 CC Model Machines...

Страница 18: ...Owner s Manual 513642 Rev 4 12 CC Model Machines...

Страница 32: ...Owner s Manual 513642 Rev 4 26 CC Model Machines...

Страница 36: ...Owner s Manual 513642 Rev 4 30 CC Model Machines...