Service Procedures

©2012 Viking Preferred Service

37

ALARMS

There are five alarms that signify faulty conditions,

they will each be covered in detail.

1. High Temp Alarm

Freezer High Temp alarm

When the freezer temperature reaches the high temp

level (15

o

F) ,set in the EEPROM at factory, for a

predetermined time (3 hours), also set in EEPROM,

the "HIGH TEMP" indicator will come on and the

"FREEZER" indicator will flash. You will also get

a continuous audible alarm, consisting of a beep

pattern (ON - 0.5 sec, OFF 2 sec's).

If the condition(s) change and the units temperature(s)

are brought back within limits as described above,

the audible alarm will turn off. The "HIGH TEMP"

and the appropriate zone (Refrigerator or Freezer)

indicator will continue to operate as described above.

To cancel the audible alarm when condition first

occurs, press and release "ALARM OFF", this will

result in shutting off the audible alarm only. To clear

the "HIGH TEMP" and flashing zone light (FREEZER

), the temperature must be brought down below the

limit temperature as described in the appropriate

zone above. Then pressing and releasing "ALARM

OFF" once will clear the "HIGH TEMP" off the screen

and the zone indicator will stop flashing.

2. Open Thermistor Alarm

The controller will sense an open thermistor condition

within 15 seconds of power on.

Open Freezer Thermistor Alarm

When the control senses that the units' thermistor

is open, "oPn" is displayed on the control along

with the zone, "FREEZER". If the control was in

the Refrigerator zone when the condition occurred,

it automatically switches over to the faulty zone

("FREEZER"). You also receive an audible alarm

consisting of five beeps that occurs only one time.

The visual alarms as described above will continue

until the condition is corrected.

The unit will continue to execute temperature control

and defrost operations as required until the condition

is corrected. The control does this through software

programming, acting as if the cut-out temperature

is never reached in the faulty zone, temperature

control in the other zone is unaffected.

The visual alarms will reset by themselves within

15 seconds of the open thermistor condition being

corrected and temperature control reverts back to

normal operation.

Содержание Quiet Cool VCFB5301

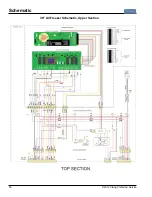

Страница 48: ...Schematic 48 2012 Viking Preferred Service 30 All Freezer Schematic Upper Section...

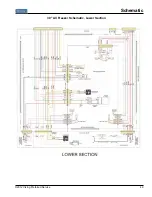

Страница 49: ...Schematic 2012 Viking Preferred Service 49 30 All Freezer Schematic Lower Section...

Страница 50: ...Schematic 50 2012 Viking Preferred Service 36 All Freezer Schematic Upper Section...

Страница 51: ...Schematic 2012 Viking Preferred Service 51 36 All Freezer Schematic Lower Section...

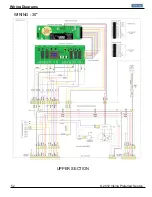

Страница 52: ...Wiring Diagrams 52 2012 Viking Preferred Service UPPER SECTION WIRING 30...

Страница 53: ...Wiring Diagrams 2012 Viking Preferred Service 53 LOWER SECTION WIRING 30...

Страница 54: ...Wiring Diagrams 54 2012 Viking Preferred Service UPPER SECTION WIRING 36...

Страница 55: ...Wiring Diagrams 2012 Viking Preferred Service 55 LOWER SECTION WIRING 36...