VSW40 Wood Stove

60300060

11

OPERATION

OPERATION

Do not use a grate or elevate fire. Build wood fire directly

on firebrick. When the stove is used for the first time the

solvents in the paint will smoke off.

Wood

This heater is designed to burn natural wood only. Higher

efficiencies and lower emissions generally result when

burning air dried seasoned hardwoods, as compared to

softwoods or to green or freshly cut hardwoods.

Only use dry seasoned wood. Green wood, besides

burning at only 60 percent of the fuel value of dry wood,

deposits creosote on the inside of your stove and along the

chimney. This can cause an extreme danger of chimney

fire. To be called “seasoned,” wood must be dried for

a year. Regardless of whether the wood is green or

seasoned, it should be stored in a well-sheltered ventilated

area to allow proper drying during the year to come. Wood

should be stored beyond recommended clearance from

combustibles.

Fuel

Even the best stove installation will not perform well with

poor fuel. If available, always use hardwood that has been

air-dried (seasoned) 12-18 months. Softwood burns more

rapidly than hardwood and has a high pitch content that

can result in creosote. Decayed wood of any type has little

heat value and should not be used.

Unseasoned (green) wood has a high moisture content.

Much of its heat value will be used to evaporate moisture

before the wood can burn. This significantly reduces the

amount of energy available to warm your home, as well

as the intensity of the fire and temperature of the exhaust

gas. Incomplete combustion and cool flue temperatures

promote creosote formation and weak draft.

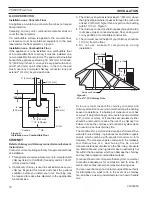

You can judge the moisture content of wood by its

appearance and weight or use a commercially available

moisture meter for exact measurement. Unseasoned wood

will be a third heavier than dry wood. Also look for cracks

(checking) in the ends of the log that result from contraction

as the wood dries. The longer and wider the cracks are,

the dryer the wood is.

Creosote

Creosote is a by-product of low-temperature stove operation,

weak draft or both. It is a tar that results when unburned

gases condense inside the flue system at temperatures

below 290 degrees F. Creosote is volatile and can generate

a chimney fire. All of the installation characteristics that

adversely affect chimney draft also promote creosote

condensation. Consequently, you can minimize creosote

accumulation with an effective chimney design and the use

of operational techniques that encourage good draft and

complete combustion.

Inspect your chimney frequently and clean it whenever

accumulation exceeds 1/4".

dO NOT BURN:

Treated Wood, Solvents, Trash, Coal,

Garbage, Cardboard, Colored Papers

NEVER USE GASOLINE, GASOLINE-TYPE LANTERN

FUEL, kEROSENE, ChARCOAL LIGhTER FLUId, OR

SIMILAR LIQUIdS TO START OR “FREShEN UP” A

FIRE IN ThIS hEATER. kEEP ALL SUCh LIQUIdS

WELL AWAY FROM ThE hEATER WhILE IT IS IN USE

INSTRUCTION FOR FIRST BURN – CURING

ThE STOVE PAINT

Your stove has been painted with the highest quality stove

paint and has special break-in procedures. The heat

generated by the normal operation of the stove, will serve

to harden the paint.

Ventilate the house

during the first three times the

stove is used. The paint on the stove will give off smoke,

carbon dioxide and an odor. Without adequate ventilation,

concentrations of smoke could irritate, or be upsetting.

Open doors and windows and use a fan

if necessary.

After the initial burns the paint will be cured and there

should be no more smoke. Each of the initial burns should

be conducted as follows:

1. The first 2 burns should be at approximately 250° F

(120° C) for approximately 20 minutes.

2. The 3

rd

burn should be between 500° F and 700° F

(260° to 370° C) for at least 45 minutes. The important

fact is the paint should be cured slowly. Avoid hot fires

during the curing process.

The best way to achieve the first burn is with kindling fires.

Prolong the fires as needed by adding more kindling.

During the curing process the paint may be gummy. Once

cured the paint will remain hard.

It is normal

to see flat

spots on painted surfaces of the stove. The flat spots on

the paint surface indicate the hotter surfaces of the stove,

and is caused by the heat radiating through the paint.

It is

also expected that shiny spots

caused by friction from

the packaging materials, will disappear during the curing

of the stove.

So . . .

1. Remember to ventilate well.

2. Allow the stove to cure before burning for long periods

at high temperatures.

3. Flat spots on the painted surfaces are normal.

4. Shiny spots on the paint surface before burning is

normal.

5. Call your dealer if you have any questions.