5

1. Introduction

To homogenize or disperse the sample can be carried out quickly and safely

by using the dispersing tools inside the beaker containing the sample.

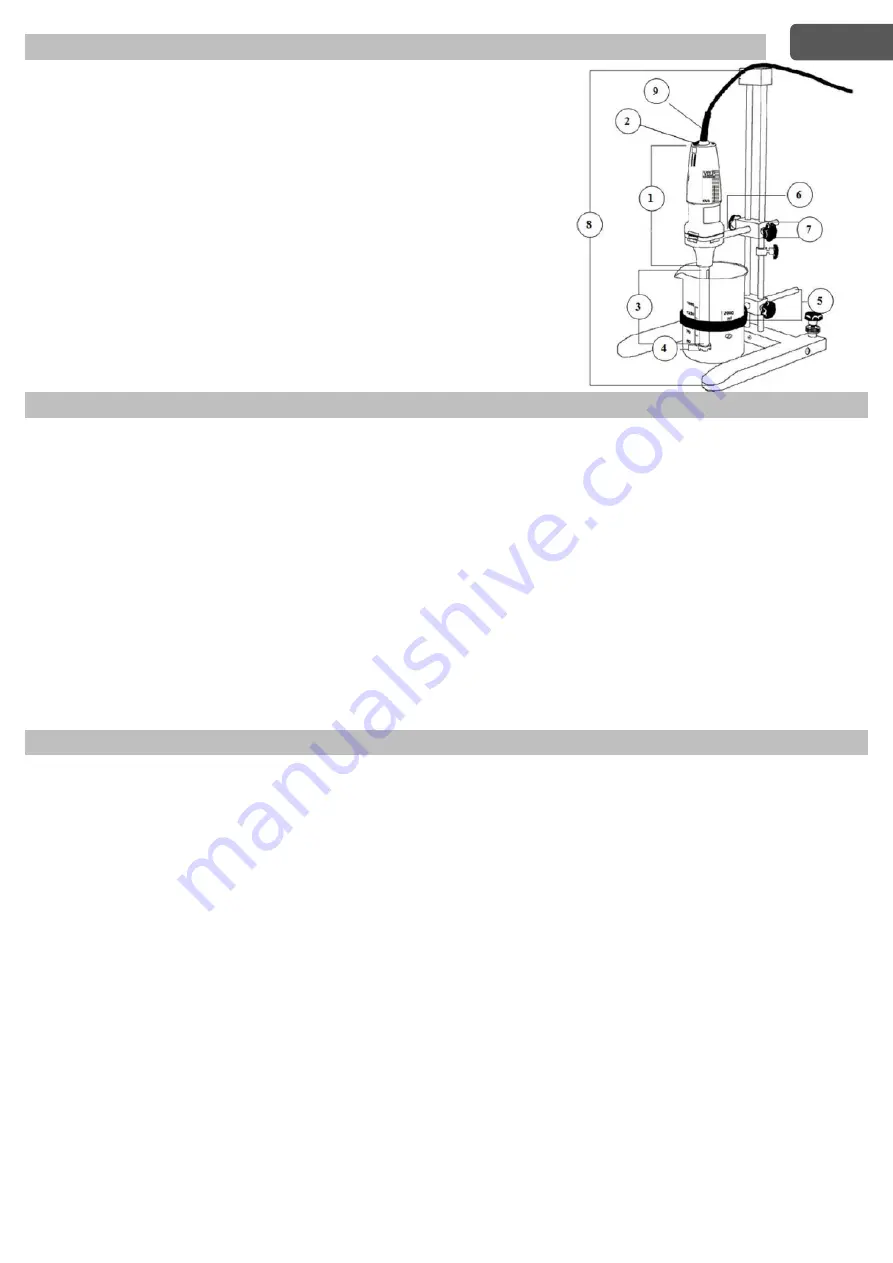

The OV5 homogenizer is composed by a smooth motor (1) with integrated

electronic speed control and permits to work in a very homogeneous way

up to 30,000 rpm.

Smooth start, thanks to general switch (2), prevents unnecessary spills

and an additional feature of automatic overload protection increases the

life span of the motor. The OV5 homogenizer has only one shaft model (3)

suitable for all the applications and configurable with different models of

rotors and stators (4) in a very safe and comfortable way.

1. Motor

2. General switch

3. Dispersing tool (shaft)

4. Rotor/Stator

5. Strap clamp

6. Homogenizer support rod

7. Bosshead

8. H-stand

9. Speed controller

2. Assembly and installation

Check the integrity of the unit after unpacking. The box includes:

•

OV5 Homogenizer

•

Instruction manual

2.1 Electrical connections

After having unpacked the instrument, place the unit on the laboratory bench.

Before connecting the instrument to the power supply, make sure that the values on the rating plate correspond to those of

the power supply. Connect the unit to the power supply using the transformer supplied.

Ensure that the socket and the relative cut-off device conform to current safety norms and are easy to reach.

2.2 Start-up

Screw the support rod into the flange of the drive motor and tighten it. For correct use the OV5 must be secured to a stand

with a bosshead. For safety reason the container with the sample should be fixed with a strap clamp.

Insert the dispersing tool into the drive flange by pressing upwards and turning clockwise until it locks into place. To remove

the dispersing tool from the flange, hold the dispersing tool and turn anticlockwise and remove the dispersing tool

downwards. The distance between the bottom of the vessel and the shaft should not be less than 10 mm. Check that the

knob of the speed control is in position “A”. Use the general switch on the front of the unit to turn the unit on (position “I”).

3. Operating controls

With the unit switched on by the general switch, use the knob on the top of the unit to select the desired speed.

Thanks to the different positions, identified by numbers, it is possible to select the following speed:

1 = 10,000 rpm

2 = 14,000 rpm

3 = 18,000 rpm

4 = 22,000 rpm

5 = 26,000 rpm

max = 30,000 rpm

For reaching the best effects, the rotor speed of OV5 should be adapted to the dispersion problem.

NOTE

: The maximum rotor speed depends on the kind of sample and its viscosity. The speed is reduced by its viscosity in

order to protect the motor from overload. If the viscosity is too high, the motor will stop automatically to prevent damage to

the equipment. The electronic control system prevents damage to the motor.

NOTE

: The instrument cannot be used without put the dispersion tool inside a sample.

NOTE:

The OV5 is designed for continues operation, however normally the ultimate fineness will be reached within few

minutes. Longer application times bring no fineness improvement, but introduce unnecessary heat into the medium and

could even cause the damage of the dispersing tool.

3.1 Overload protection

When the motor overloads and the power supply cuts off, switch off the general switch, disconnect the dispersing tool and

re-start the instrument as fast as possible, without the load in order to accelerate cooling by the built-in fan.

3.2 Disassembling the dispersing tool

1. Hold the dispersing tool with a cloth (to avoid cutting of your hand due to sharp edges at the stator). At the same time turn

the shaft tube clockwise. Screw the shaft tube of the stator and pull it over the axle and put it aside.

2. Now hold the rotor with a cloth and turn the axle anticlockwise. Slowly screw the axle from the rotor and put it aside.

EN