28

6 Setup

VEGASWING 63 • Two-wire 8/16 mA

29232-EN-180704

2. Push the mode switch (min./max.) on the signal conditioning

instrument.

Check if the switching status changes (signal lamp - switching

status). By doing so, you can check the function of the measuring

system.

If this is not the case, then there is a fault in the measuring sys-

tem.

Make sure the connected downstream devices are activated dur-

ing the function test.

Implementation - Function test

If you are using a signal conditioning instrument of type VEGATOR

636 for this purpose, you can also carry out the test with the inte-

grated test key. The test key is recessed in the front plate of the signal

conditioning insturment. Push the test key for > 2 seconds with a suit-

able object (screwdriver, pen, etc.).

When the VEGASWING 63 is connected to a processing system or

an SPLC, you have to interrupt the connection cable to the sensor for

> 2 seconds. The switching delay must be set to 0.5 s.

After releasing the test key or interrupting the connection cable to the

sensor, the complete measuring system can be checked on correct

function. The following operating conditions are simulated during the

test:

•

Fault message

•

Empty signal

•

Full signal

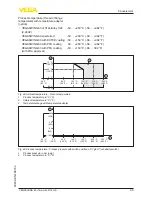

3

2

1

16

±1,5

I/mA

8

±1,5

< 3,6

0,6

±0,2

1,5

±0,5

1,5

±0,5

t/s

Fig. 30: Flow chart of the function test

1 Fault message

2 Empty signal

3 Full signal

Check if all three switching conditions occur in the correct sequence

and the stated time period. If this is not the case, there is a fault in the

measuring system (see also the operating instructions manual of the

signal conditioning instrument). Keep in mind that connected instru-

ments are activated during the function test. By doing this, you can

check the correct function of the measuring system.