20

6 Setup with a controller

VEGACAL 67 • For connection to a controller

31761-EN-200317

6.3 Continuous level measurement

Continuous measurement requires a constant dielectric value, i.e. the

measured product should have constant properties.

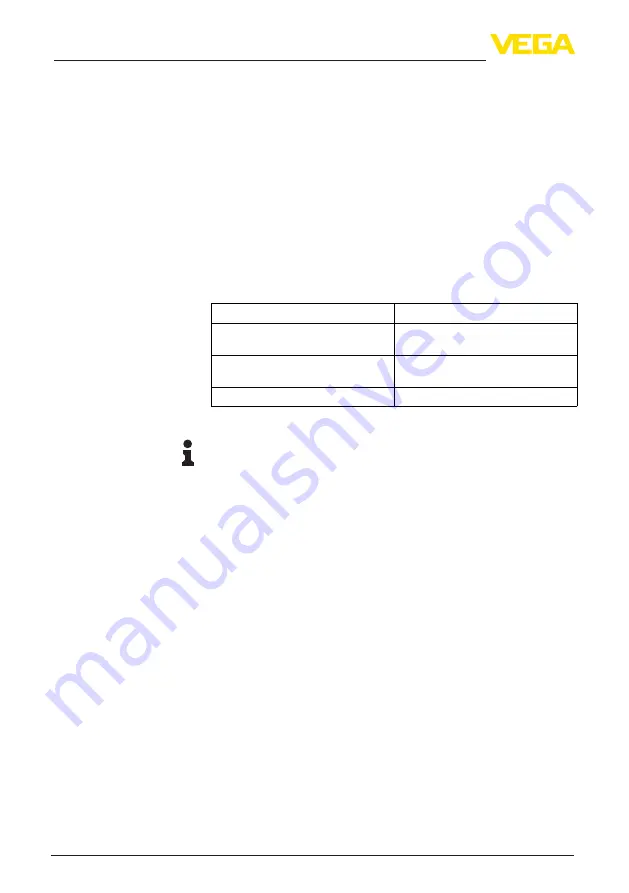

Select the stage with the measuring range selection switch on the

electronics module of the probe according to the following table.

Look in the row that corresponds to your product and select an ap-

propriate range according to the length of your probe.

The listed lengths do not completely correspond to those of the

actually available measuring probes. If the product has a dielectric

constant that lies between the values stated in the table, the max. per-

missible probe length for each range must be calculated accordingly.

For longer lengths or if there is no information available in the chart,

select range 3. If you are not sure, always set the measuring range

selection switch to the next higher stage.

VEGACAL 67

non-conductive and dielectric con-

stant = 2

0 - 6 m = range 1/6 - 30 m = range 2

non-conductive and dielectric con-

stant = 10

0 - 1 m = range 1/1 - 5 m = range 2

conductive or dielectric constant > 50 -

Tab. 1: Range setting

Tip:

For min. adjustment the vessel should be as empty as possible, and

for max. adjustment, as full as possible. If the vessel is already full,

start with max. adjustment.

1. Set range changeover switch on the capacitive probe according

to the above table

2. When connecting to an analogue input card of a PLC, take note

of the operating instructions manual of the input card. The vessel

must be as empty as possible for empty adjustment and as full as

possible for full adjustment.

If the indication cannot be set to 100 %, proceed as follows:

•

If the indication does not reach 100 %, you have to set the range

selection switch on the probe one stage lower.

•

If the indication exceeds 100 % and cannot be reset, you have

to set the range selection switch of the probe to the next higher

stage. In both cases you have to repeat the adjustment.

1. Set range changeover switch on the capacitive probe according

to the above table

2. Carry out the adjustment on the controller (see operating

instructions manual of the controller: "Adjustment with medium")

When connecting to an analogue input card of a PLC, take note of the

operating instructions manual of the input card. The vessel must be as

empty as possible for empty adjustment and as full as possible for full

adjustment.

If the indication cannot be set to 100 %, proceed as follows:

General information

Analogue input card of

a PLC

VEGAMET series 300, 600

controller

Содержание VEGACAL 67

Страница 3: ...3 Contents VEGACAL 67 For connection to a controller 31761 EN 200317 Editing status 2020 03 03...

Страница 33: ...33 Notes VEGACAL 67 For connection to a controller 31761 EN 200317...

Страница 34: ...34 Notes VEGACAL 67 For connection to a controller 31761 EN 200317...

Страница 35: ...35 Notes VEGACAL 67 For connection to a controller 31761 EN 200317...