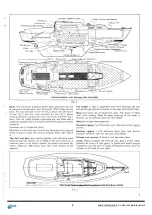

Interior and equipment

M a n y suggestions have been made for alterations to the

interior. The interior and equipment now p r o v i d e d is better

than that on the e a r l y V E G A : s . The best possible f u n c t i o n

has been c o n s i d e r e d . A f t e r that, the a c c o m m o d a t i o n is a

c o m p r o m i s e b e t w e e n s t r i c t e c o n o m y and desirable extras.

Further i m p r o v e m e n t s w i l l be made provided they do not

result in an increase in the price. The number of berths can

be increased (for children) by placing an extra mattress

b e t w e e n the bunks in the fore peak or by providing upper

bunks above t h o s e in the main cabin. These items can be

b o u g h t as extras. A special locker f o r c r o c k e r y and a b o o k

shelf can also be s u p p l i e d . The saloon berths can be f i t t e d

w i t h canvas lee b o a r d s to prevent y o u falling out in a sea-

w a y or when the b o a t is heeling. See the price list f o r V E G A

extra equipment.

Varnish, glue and fastening, cleaning

The interior j o i n e r y is mainly of resin glued marine p l y w o o d

w i t h surface v e n e e r s of sapele on g a b o o n cores. The finish

should normally last for several y e a r s but its life may be

p r o l o n g e d by p o l i s h i n g w i t h furniture polish. A f t e r a p e r i o d

the s u r f a c e finish will have to be r e n e w e d . The v a r n i s h e d

parts can be t r e a t e d with either alkyd or polyurethane based

varnish in a c c o r d a n c e w i t h the manufacturer's i n s t r u c t i o n s .

O t h e r parts can be painted with marine paint. Teak (hatches,

handrails, etc) s h o u l d be oiled several times each s e a s o n .

W h e n necessary, the teak parts s h o u l d be s c r a p e d and

s a n d e d . The best and cheapest " t e a k o i l " is a mixture of

t w o p a r t s raw linseed oil and one p a r t turpentine t h i n n e r s .

It can be put on w i t h either a brush or a soft cloth. Excess

oil s h o u l d be w i p e d off w i t h a cloth moistened w i t h t h i n n e r s .

If y o u w i s h to fix h o o k s or other fittings to the boat they can

either be screwed or glued on. Fittings can be s c r e w e d to

all w o o d parts, including the cabin aft bulkhead, w h i c h is

f a c e d w i t h p l y w o o d . Holes should be drilled for s c r e w s .

Fittings that do not carry a great load can be s c r e w e d on to

plastic surfaces w i t h short stainless steel self tapping s c r e w s .

It is v e r y important that the right size holes are d r i l l e d first.

A dab of epoxy glue on the threads w i l l provide c o n s i d e r a b l e

holding power. Epoxy glue is so strong that it can be used

to glue metal f i t t i n g s on to the plastic surfaces. This cannot

be d o n e , however, on thermo plastic.

Fittings that have to take a load must be attached w i t h

t h r o u g h bolts. The s a n d w i c h deck w i l l take the load of such

bolts only where t h e deck is filled w i t h w o o d or special fiIIer.

(See Figure 4). If bolts must be used in other p l a c e s , the

D i v i n y c e l l filling s h o u l d be r e m o v e d round the hole and

g l a s s f i b r e and resin put to form a strengthening " t u b e "

round the bolt. A piece of wood should be fitted under the

nuts to spread the load. Bolt holes will leak if the bolts are

not p a c k e d with a rubber gasket or sealing c o m p o u n d . G l a s s -

f i b r e does not e x p a n d when moist, so leaks are not self

sealing as is s o m e t i m e s the case w i t h a w o o d boat.

The curtains are c o t t o n and can be w a s h e d in water. For the

c a r p e t s a foam d e t e r g e n t can be used. The c o v e r s f o r t h e

matresses are synthetic and may be removed and dry-

cleaned, but it is a lot of work to p u t the covers back again.

W i t h a foam d e t e r g e n t it is possible to wash the c o v e r s

w i t h o u t removing t h e m . Test the detergent on a spot on the

back side to ascertain that the c o l o u r does not fade.

Fresh water

The w a t e r tank holds 65 litres ( 1 4 % gals). The deck filler is

situated right f o r w a r d on the fore deck. The level of the w a t e r

in the plastic t a n k can be c h e c k e d through the v e r t i c a l

opening in the b u l k h e a d aft of the tank. A thin breather pipe

w h i c h finishes j u s t under the deck is fitted parallel to the

filling pipe. If the tank is completely f i l l e d the water level

will rise up the breather pipe and a small amount of w a t e r

will find its w a y into the b i l g e ; it can be removed easily w i t h

the bilge pump. If the tank is c o m p l e t e l y filled, water may

also run o u t into the s i n k and wash b a s i n if the plastic c a p s

have not been placed over the w a t e r outlet pipes. If it is

desired to flush through the tank and supply hoses, the

plastic cap should be left off at the sink and the drain plug

r e m o v e d . W a t e r can then run freely t h r o u g h the s y s t e m ,

into the sink and o v e r b o a r d . A large lid is fitted to the t a n k

to facilitate inspection and cleaning. W h e n sailing, the f r e s h

water outlet in the w a s h basin should be covered w i t h the

plastic cap (or the w a s h basin locked in the pulled out p o s i -

tion) because with a full w a t e r tank, large quantities of w a t e r

may run out into the boat w h e n heeling on the port tack. The

f o r w a r d foot pump in the galley is for fresh water and the

aft one for sea water.

Skin fittings and hose clips

All skin fittings below the waterline — inlet and outlet f r o m

the toilet, outlet from the sink, sea w a t e r intake for the galley,

and cooling water for the engine have sea cocks to p r e v e n t

the water from entering the huil if a hose or pipe should be

damaged. Skin fittings for the exhaust and cockpit drains

have no sea cocks since they can be reached from deck and

b u n g e d up if need be.

All hose attachements s h o u l d be c h e c k e d regularly for leaks

and the hose clips t i g h t e n e d if necessary. There are drains

from the cockpit seats d o w n to the c o c k p i t floor. W h e n the

boat is heeling a c o n s i d e r a b l e amount of water can run

t h r o u g h the leeward hose if it is raining hard or s p r a y is

coming aboard. Should the seat drain hose come adrift, w a t e r

w i l l run straight into the boat. The hose fittings should, t h e r e -

fore, be checked frequently.

Ventilation and heating

The bilge is provided w i t h a special v e n t i l a t o r with an electric

extractor fan. This s u c k s any fuel fumes or gas f r o m the

deepest part of the boat through a hose and so p r e v e n t

explosions. The fan s h o u l d be run from 2 to 5 minutes b e f o r e

starting the engine or lighting a naked flame.

The ventilation system has been d e s i g n e d with scientific

t h o r o u g h n e s s by a f o r m e r chief of the S w e d i s h d e f e n c e

research, Hugo Larsson. This is p r o b a b l y the only system

that provides a well v e n t i l a t e d and dry boat without the use

of electric fans. On hot s u m m e r days the temperature inside

the boat will be cooler than that outside.

The system is based on the principle of all air being let into

the accommodation t h r o u g h a ventilator in the cockpit. The

hatch must be kept c l o s e d . The air is taken through ducts

next to the huil of the boat below the waterline which cools

the air and causes the moisture to condense against the

Fig. 20. Ventilation system.

15

17