19

Vasco

Kruishoefstraat 50

3650 Dilsen-Stokkem

Belgium

Tel.: +32(0)89790411

__________________________________________________________________________

3.

Maintenance

Vasco advices to clean the electric preheating element every 4 years.

1)

Remove the plugs of the ventilation unit and the preheating element from the sockets.

2)

Wait 10 minutes for the preheating element to cool down

3)

Take the preheating element off the installation

4)

Clean the metal elements inside the preheating element*

5)

Reinstall the preheating element onto the installation

6)

Put the plugs of the ventilation unit and the preheating element back in the sockets.

*Cleaning can be done with pressurized air and/or a small brush.

Do not use any chemical/liquids cleaners.

Failure to perform the maintenance work on time will ultimately result in the appliance no longer

functioning optimally.

4.

Technical information

The preheating elements essentially consist of an insulated PTC heat register that is built into a

housing consisting of metal and plastic. The preheating element will be controlled by the software on

the circuit board of the ventilation unit.

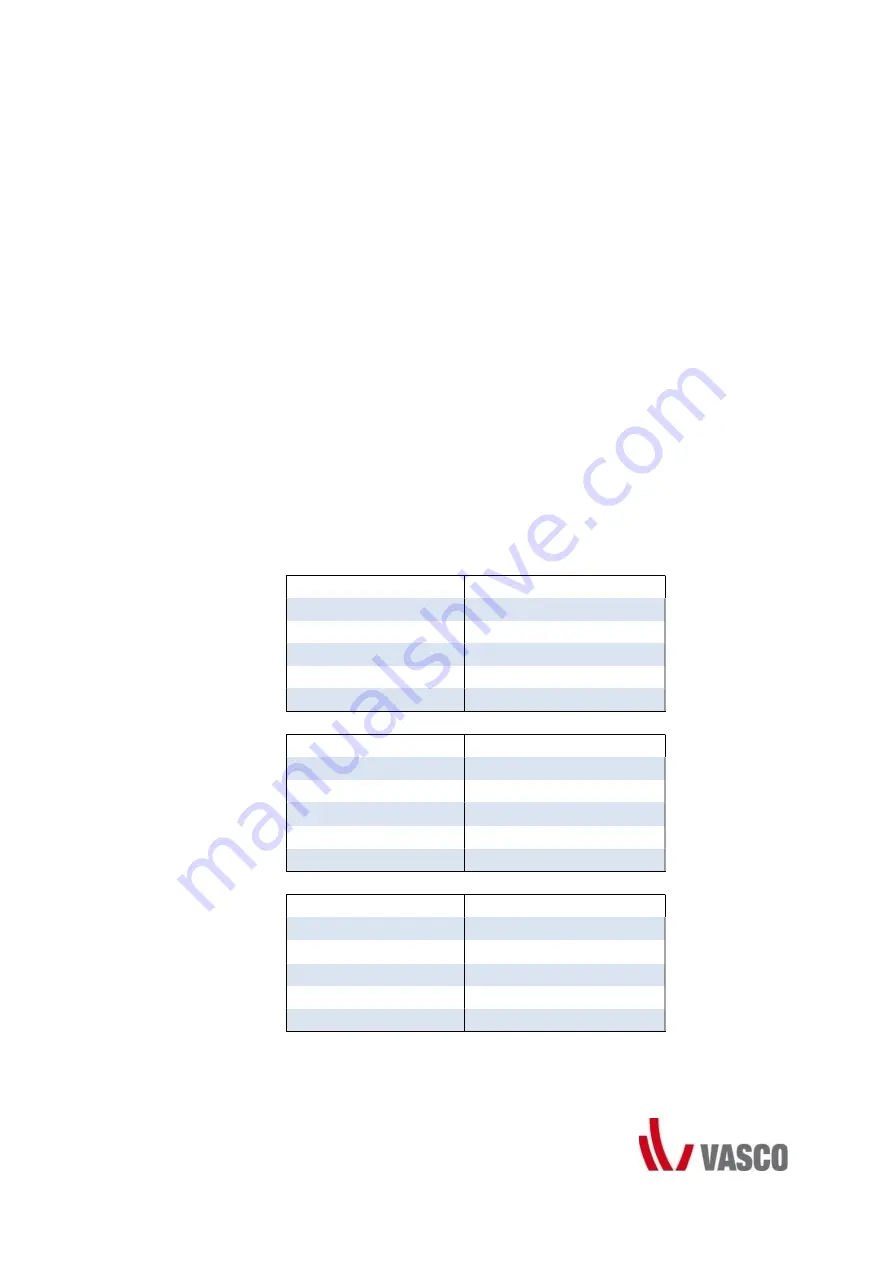

Technical data:

Name

Elec. Preheater D150 – 700W

Nominal power Pnom

600W

Max. power Pmax

700W

Differential pressure Δp*

17,5Pa

*21°C; 275m³/h

Connection diameter

DN150 (female)

Outside diameter

167 x 215 x 170mm (H x W x D)

Name

Elec. Preheater D180 – 700W

Nominal power Pnom

600W

Max. power Pmax

700W

Differential pressure Δp** 13,7Pa

**21°C; 400m³/h

Connection diameter

DN180 (female)

Outside diameter

168 x 240 x 200mm (H x W x D)

Name

Elec. Preheater D180 – 1400W

Nominal power Pnom

1200W

Max. power Pmax

1400W

Differential pressure Δp*** 48,3Pa

***21°C; 600m³/h

Connection diameter

DN180 (female)

Outside diameter

168 x 240 x 200mm (H x W x D)