INSTRUCTIONS FOR USE

24

87-900-973-01

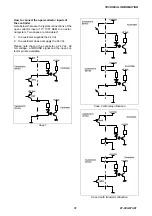

PUMP FIXING

!

WARNING!

If a rotor failure occurs, the connection of the pump to the sys-

tem could be subjected to a significant torque. If the connection

is not sufficient to withstand that torque, the pump could detach

from the system or the motor housing could detach from the

pump envelope. In this case metal fragments could be pro-

jected from the pump or system, which could cause serious

injury or death and/or damage to surrounding equipment.

Fix the TV 1001 SEM in a stable position, mounting the inlet

flange of the turbopump to the system counter-flange, with a

connection capable of withstanding a torque of 8900 Nm

around its axis.

For example the ISO-K flange can be fixed using high strength

steel clamps (like Varian model IC63250DCMZ).

The following table shows, for each flange, the necessary num-

ber of IC63250DCMZ clamps and the relevant fixing torque.

FLANGE N. FIXING

TORQUE

ISO 200 K

8

35 Nm

The turbopump with ISO 200 F inlet flange must be fixed to the

vacuum chamber by means of the appropriate Varian hard-

ware. See the appendix "Technical Information" for a detailed

description.

The TV 1001 SEM can be installed in any position.

NOTE

The TV 1001 SEM cannot be fixed by means of its base.

!

CAUTION

The TV 1001 SEM belongs to the second installation (or over-

voltage) category as per directive EN 61010-1. Connect the

device to a mains line that satisfy the above category.

The TV 1001 SEM has Input/Output and serial communication

connectors that must be connected to external circuits in such a

way that no electrical part is accessible.

Be sure that the insulation of the device connected to the TV

1001 SEM is adequate even in the case of single fault as per

directive EN 61010-1.

For installation of optional accessories, see "Technical Infor-

mation".

USE

This paragraph details the fundamental operating procedures.

Make all electrical an pneumatic connections before the use of

the system.

While heating the vacuum chamber, the temperature of the inlet

flange must not exceed 120 °C.

!

WARNING!

Never use the turbopump when the inlet flange is not con-

nected to the vacuum chamber or is not blanked.

Do not touch the turbopump or any of its accessories during the

heating process. The high temperatures may cause burns.

!

CAUTION

Avoid impacts, oscillations or harsh movements of the pump

when in operation. The bearings may become damaged.

Use air or inert gas free from dust or particles for venting the

pump. The pressure at the vent port must be less than 2 bar

(above atmospheric pressure).

For pumping aggressive gases, these pumps are fitted with a

special port to allow a steady flow of inert gas (like N2, Ar) for

pump bearing protection (see the appendix "Technical Informa-

tion").

!

WARNING!

When employing the pump for pumping toxic, flammable, or

radioactive gases, please follow the required procedures for

each gas disposal.

Do not use the pump in presence of explosive gases.

Switching on and Use of TV 1001 SEM

To switch on the TV 1001 SEM it is necessary to supply the

mains to the controller (optional). It automatically recognizes

the interlock and start signals presence and start up the pump.

The first pump start up is in “Soft Start” mode. When the start

up cycle is finished, the “Soft Start” mode automatically is dis-

abled, and the following start ups are without the “Soft Start”

mode. To re-enable the “Soft Start” mode it must be activated

by the suitable software command (see the paragraph “RS

232/485 COMMUNICATION DESCRIPTION” in the appendix

“Technical Information”).

The green LED located on the TV 1001 SEM base front panel

indicates with its flashing frequency the system operating con-

ditions:

-

with no flashing: the pump is normally rotating;

- slowly flashing (period of about 400 ms): the system is in

ramp, or in braking, or in Stop, or in “Waiting for interlock”

status;

-

fast flashing (period of about 200 ms): error condition.

TV 1001 SEM Switching off

To switch off the TV 1001 SEM it is necessary to remove the

mains from the controller. It immediately stops the pump.

Emergency Stop

To immediately stop the TV 1001 SEM in an emergency condi-

tion it is necessary to remove the supply cable from the mains

plug.

MAINTENANCE

The TV 1001 SEM does not require any maintenance. Any work

performed on the system must be carried out by author-ized

personnel.

!

WARNING!

Before carrying out any work on the system, disconnect it from

the mains, vent the pump by opening the appropriate valve,

wait until the rotor has stopped turning and wait until the sur-

face temperature of the pump falls below 50 °C.

In the case of breakdown, contact your local Varian service

center who can supply a reconditioned system to replace that

broken down.

NOTE

Before returning the system to the constructor for repairs, or

replacement with a reconditioned unit, the "Health and Safety"

sheet attached to this instruction manual must be filled-in and

sent to the local sales office. A copy of the sheet must be in-

serted in the system package before shipping.

If a system is to be scrapped, it must be disposed of in accor-

dance with the specific national standards.