BDR-595 E EuroAdela

34

MOWING DISK DRIVE

Pos. Name

Size

Drawing-Standard

Order. No.

Pcs

1 Brake shoe

22 9 1664 024

189 014

2

2 Driven belt pulley

22 9 3325 012

189 004

1

3 Upper disk

22 9 5025 007

189 056

1

4 Brake cam

22 9 8032 048

196 003

1

5 Pulley arm

32 0 3330 034

196 010

1

6 Drive

32 0 3821 017

189 058

1

7 Drive Shaft

32 0 3822 022

196 005

1

8 Lower disk

32 0 5020 011

189 057

1

9 Knife

32 0 6030 009

189 060

3

10 Shim block

42/36/0,1

32 0 9220 024

110 012

3

12 Distance ring

32 0 9220 199

189 011

1

13 Housing

32 1 9220 126

127 014

1

14 Pulley

632 0 3325 040

189 586

1

15 Flange

632 0 3821 015

189 059

1

16 Washer

14

632 0 9220 205

189 061

3

17 Brake shoe pin

632 0 9311 152

196 524

1

18 Pulley bearing

632 0 9320 071

196 528

1

19 Brake shoe spring

632 0 9746 044

189 511

1

20 Spring

TZ1,8x16,2x63x20 FEVOZ Slavièín

169 514

1

21 Spring

TZ0,8x8,8x95,2x100 FEVOZ Slavièín

189 516

1

22 Bolt

M6x14

ÈSN 02 1151.25

189 557

6

23 Bolt

M6x45

ÈSN 02 1103.25

195 523

1

24 Bolt

M6x55

ÈSN 02 1101.25

196 523

1

25 Bolt

M10x30

ÈSN EN 24017

189 545

3

26 Nut

M6

ÈSN 02 1401.25

1800141

6

27 Nut

M6

ÈSN 02 1492.25

168 516

2

28 Nut

M10

ÈSN 02 1401.55

189 561

3

29 Washer

6,4

ÈSN 02 1702.15

189 571

4

30 Washer

8,4

ÈSN 02 1702.15

131 517

1

31 Washer

10,5

ÈSN 02 1702.15

131 518

3

32 Washer

21

ÈSN 02 1702.15

124 530

1

33 Washer

6,1

ÈSN 02 1740.05

6510920

6

34 Pin

5x40

ÈSN 02 2156

196 502

1

35 Feather

5x5x25

ÈSN 02 2562

189 574

1

36 Feather

6x6x25

ÈSN 02 2562

169 503

1

37 Retaining ring

8

ÈSN 02 2930

195 534

2

38 Retaining ring

10

ÈSN 02 2930

6021519

1

39 Retaining ring

20

ÈSN 02 2930

110 515

2

40 Retaining ring

35

ÈSN 02 2931

126 503

1

41 Retaining ring

42

ÈSN 02 2930

136 506

2

42 Bearing

6300 2RS

ÈSN 02 4630

189 585

1

43 Bearing

6004 2RS

ÈSN 02 4630

9943158

4

Set of spare knives

129 8565 144

189 066

Содержание BDR-595 E EuroAdela

Страница 1: ...Drum mower BDR 595 E EuroAdela Instructions for use...

Страница 8: ...BDR 595 E EuroAdela 8 LwA 2 1 3 4 5 6 7 8 11 12 9 10...

Страница 28: ...BDR 595 E EuroAdela 28 8 List of components...

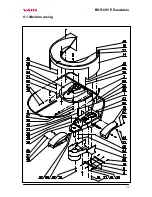

Страница 29: ...BDR 595 E EuroAdela 29 8 1 Machine casing...

Страница 31: ...BDR 595 E EuroAdela 31 8 2 Handlebars...

Страница 33: ...BDR 595 E EuroAdela 33 8 3 Mowing disk drive...

Страница 35: ...BDR 595 E EuroAdela 35...

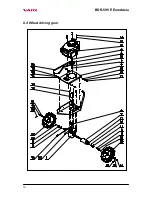

Страница 36: ...BDR 595 E EuroAdela 36 8 4 Wheel driving gear...

Страница 38: ...BDR 595 E EuroAdela 38 8 5 Gearbox...