BDR-595 E EuroAdela

10

6 Instructions for use

6.1 Machine assembly

Ask your dealer to provide machine unpackaging and briefing.

Grip points for unpackaging the machine from the box: Front – Mowing disk; Rear – the

„U“ tube of the machine frame.

Should you do the machine assembly yourself, please follow the below instructions:

Note: Washer size (e.g. Ø6.4mm) is always presented as the diameter of washer hole.

1. Take the machine out from the box and all parts from the packages.

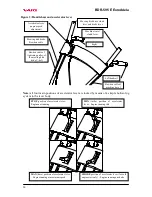

2. Slip the front part of screen frame (1a) into the rear part of screen frame (1b) and connect

them by means of M6x16 bolts (2) with small flat washers Ø6.4mm (3).

3. Put the assembled screen frame on a flat surface (table, floot, etc.) and slip the screen (4)

onto the longitudinal beam on the front part of screen frame with its back side out. Bolt

the screen (4) to the assembled apron frame by means of two bolts M6x16 (2) with

washers Ø6.6mm (5) and self-locking nuts M6 (6) with small flat washers Ø6.4mm (3).

Provide the bolt heads with plastic caps (7). Then sling the screen sides over the screen

frame so that they are in the position illustrated in Fig. 2a.

4. Turn the handlebars (8)so that the handrails point to the rear of the machine. Attach the

handlebars (8) onto the frame tubes at a required height by means of bolts with squares

(9), small flat washers Ø8.4mm (10) and plastic rosebits with internal tread (11). Fix the

Bowdens to the tubes of handlebars by means of two plastic tightening tapes.

Driving wheels

Engine

Handleba

rs

Mowing disk drive gear

lever with brake

Accelerator lever (adjustment

of engine speed)

Machine travel gear

clutch lever

Plastic rosebit to

adjust handlebars

height

Upper

casing

Figure 1: Drum mower BDR-595 E EuroAdela

Starter grip

Side apron

Front grip handrail (e.g. for

lifting the machine etc.)

Rear grip points

(for steering, lifting

or loading the

machine)

Apron

Содержание BDR-595 E EuroAdela

Страница 1: ...Drum mower BDR 595 E EuroAdela Instructions for use...

Страница 8: ...BDR 595 E EuroAdela 8 LwA 2 1 3 4 5 6 7 8 11 12 9 10...

Страница 28: ...BDR 595 E EuroAdela 28 8 List of components...

Страница 29: ...BDR 595 E EuroAdela 29 8 1 Machine casing...

Страница 31: ...BDR 595 E EuroAdela 31 8 2 Handlebars...

Страница 33: ...BDR 595 E EuroAdela 33 8 3 Mowing disk drive...

Страница 35: ...BDR 595 E EuroAdela 35...

Страница 36: ...BDR 595 E EuroAdela 36 8 4 Wheel driving gear...

Страница 38: ...BDR 595 E EuroAdela 38 8 5 Gearbox...