I N S T A L L A T I O N

©Vantage, 8/12/2016 / IS-0521-B

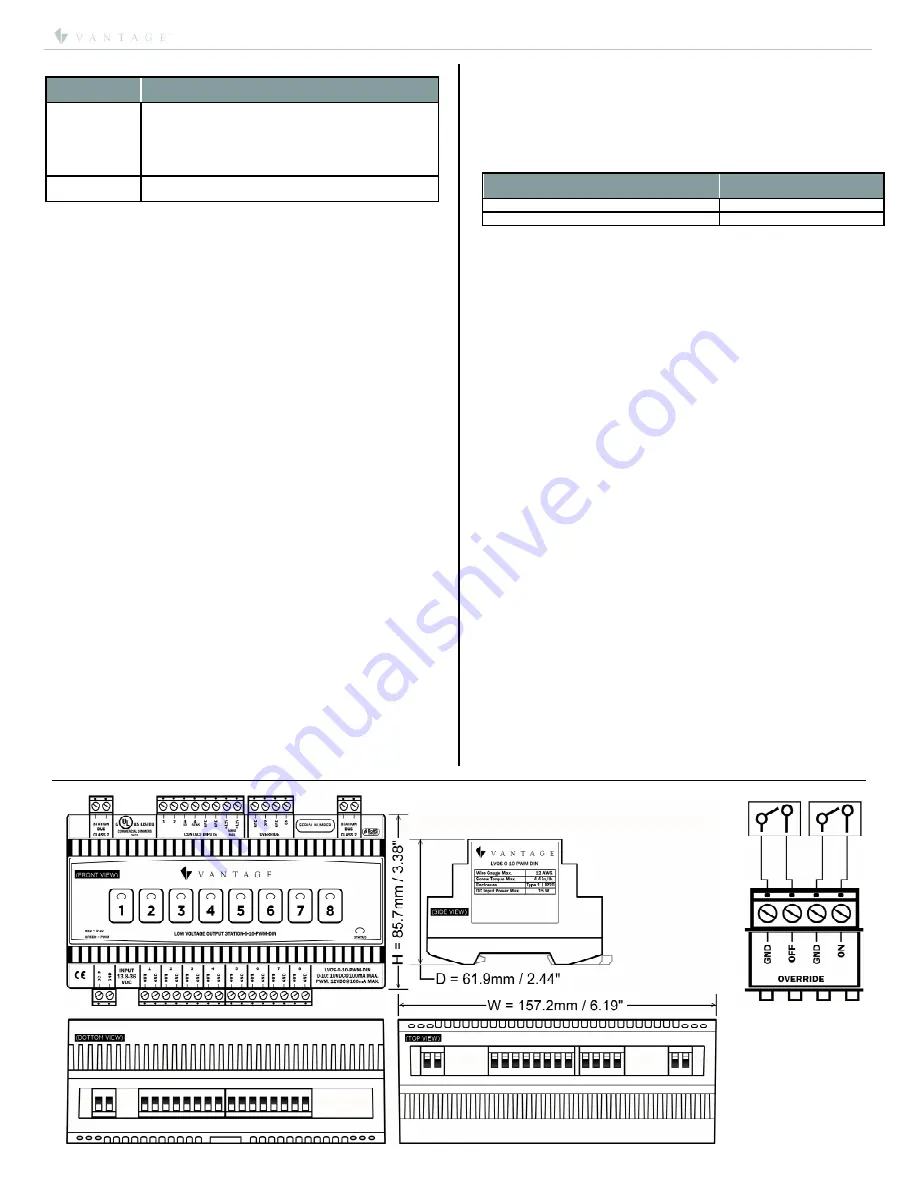

DIN Low Voltage Output Station — MODEL: LVOS-0-10-PWM-DIN

page 2 of 2

Override

Wiring

Example

Button Operation

Button

Action

Load Operation

Press/Release

1.

The load ramps to 100%

or

fades to 0% over

three seconds, alternating with every other

press and release.

2.

If the button is pressed again before the three

seconds time, the load stops ramping/fading

at its current level.

Press and

Hold/Learn

Press and Hold

and

learned level

features are

not

supported from the front panel buttons.

Installation

Installation of Vantage products should be performed or

supervised by a

Certified Vantage Installer

. Each LVOS-0-10-PWM-

DIN must be installed inside of a properly vented and covered DIN

enclosure. Connection torque is 4.4 inch pounds.

Station Connection

The LVOS-0-10-PWM-DIN connects to a Vantage System via

Station Bus. Two screw terminals are located in the low voltage

section of the electrical box (through top). The two connectors are

internally wired, in parallel, to facilitate daisy chaining the station

bus. The wire should comply with the Vantage Station Bus wiring

specification.

Remote Infrared Receiver or Dry-Contact

A remote infrared receiver (part # REMOTEIR) may be connected

to the LVOS-0-10-PWM-DIN dry-contact 3. This terminal is not

compatible with remote infrared receivers from other

manufacturers.

The receiver connects to +12V, IR IN (dry contact 3) and Gnd. If not

used with an IR receiver this input may be used as a standard dry

contact input, connecting the contact between IR IN (dry contact

3) and Gnd.

Sensor Input or Dry-Contact

Dry contact 4 connects to +12V, SENSOR IN and Gnd. If not used

for a light sensor, this input may be used as a standard dry contact

input, connecting the contact between SENSOR IN (dry contact 4)

and Gnd.

Wiring

Loads 1 – 8, Low Voltage outputs, should be limited to 250 feet /

76.2 meters for each wire run, using a minimum of 18AWG /

0.823mm2 gauge wire. All connections use 4.4 inch pound torque.

Stranded wire recommended.

Override

The station supports two Override modes, ON and OFF. When

either switch is closed, using a simple toggle switch, all loads are

ON or OFF depending on which override loop is closed. However,

the ON override takes precedence over the OFF override if both

switches are closed. NOTE:

Station does not communicate to

controller when in override.

Power Connection

Connect the 13.8 – 36VDC power feed. Vantage recommends the

PSU36-DIN 36VDC

or

ACPDXXSM2 24VDC

power supplies*. This

provides power for the LVOS-0-10-PWM-DIN and is required for

the station to operate. Use 16AWG / 1.31mm

2

wire between power

supply and stations using a daisy-chain topology.

Total

wire length

for all stations connected to power supply should not exceed 100ft

/ 30.5m.

*DIN Power Supply

LVOS-0-10-PWM-DIN

Stations Supported

PSU36-DIN – 36V DC 3.5A 130W Max

Supports up to 8 Stations

ACPDXXSM2 – 24V DC 2.5A 60W Max

Supports up to 4 Stations

Configuration

When the LVOS-0-10-PWM-DIN station is first connected to the

Station Bus, the diagnostic LED will blink twice followed by a pause.

In Design Center, click on Configure Stations, the Status LED will

blink 5 times followed by a pause. To finish configuring press any

button on the Station 3 times. The station may also be configured

by typing the serial number in the project file, using this method

the station will automatically be configured when the system is

programmed.

Diagnostic Information

The Status LED blinks evenly or flashes 2, 3, 4 or 5 times followed

by a pause to indicate status information.

Off: The station is not powered. A power connection has not been

made.

One Even blink: Station is operating correctly and is configured.

Two blinks: Station is operating correctly but is not configured.

Three blinks: Station is

not

communicating with the Main

Controller. Verify that station bus wiring conforms to Vantage

guidelines.

Four blinks: Station problem. Please contact the factory.

Five blinks: Configuration mode.

Firmware Upgradable From Design Center

1.

The station must always be configured and programmed to the system

in order to perform a firmware update.

2.

Click on

System | Update Firmware | Update DIN LVOS Firmware

.

3.

Select the checkbox for each DIN LVOS PWM station needing the

firmware upgrade.

4.

Complete the upgrade – wait for the process to finish.

Placing Station In Boot Code

If the application code is corrupted it may not be possible for Design

Center to connect to the DIN LVOS PWM station to update. If this

condition is suspected, place the DIN LVOS PWM station into boot code

and then update following the steps above.

1.

Remove DC voltage power to the station.

2.

Press and hold buttons 2 and 3 while DC voltage power is restored.

3.

All of the station’s load and status LED lights will flash in unison.

4.

While in this mode attempt the regular firmware update steps 2-4 again.

(Above -

Firmware Upgradable From Design Center

)

5.

When the firmware update is finished the update dialog box will display

a green checkmark and the station will reboot automatically.

Line Drawings